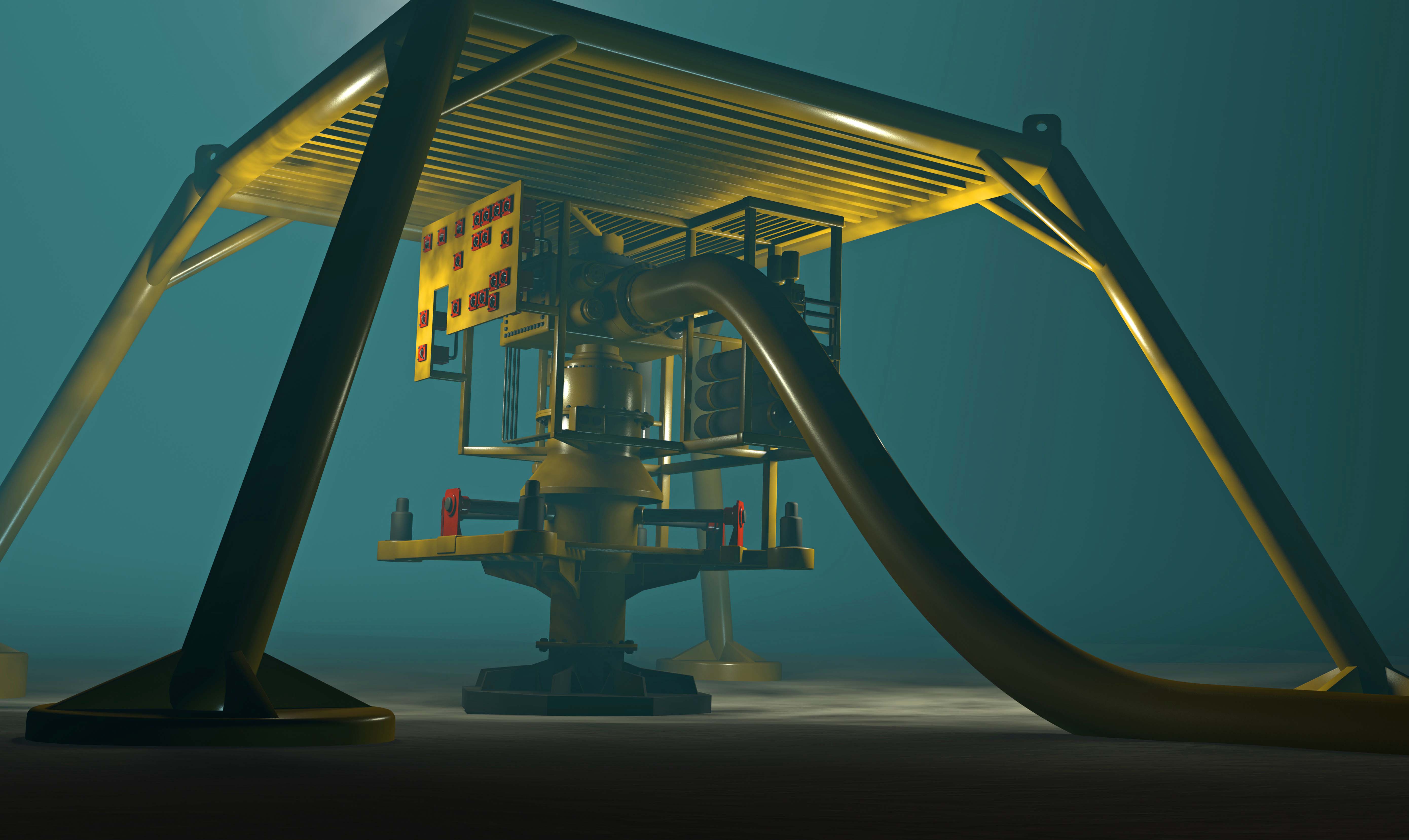

Cutting-edge care for underwater assets

Intelligent and world-leading subsea inspection solutions to inspect structures and pipelines of various geometries.

One of the most reliable subsea inspection systems in the world since 1990

Underwater structures and pipelines are subject to corrosion and natural wear and tear. The risks and implications of undetected flaws can be serious safety-wise and financially, impacting assets' expected lifetime.

Subsea inspection tailored to any need provides peace of mind

Combining expertise within integrity management, material technology, monitoring, and structural and engineering design, our subsea solutions promise unparalleled accuracy and can be tailored to solve any challenge.

Get detailed data for qualified decisions about underwater assets

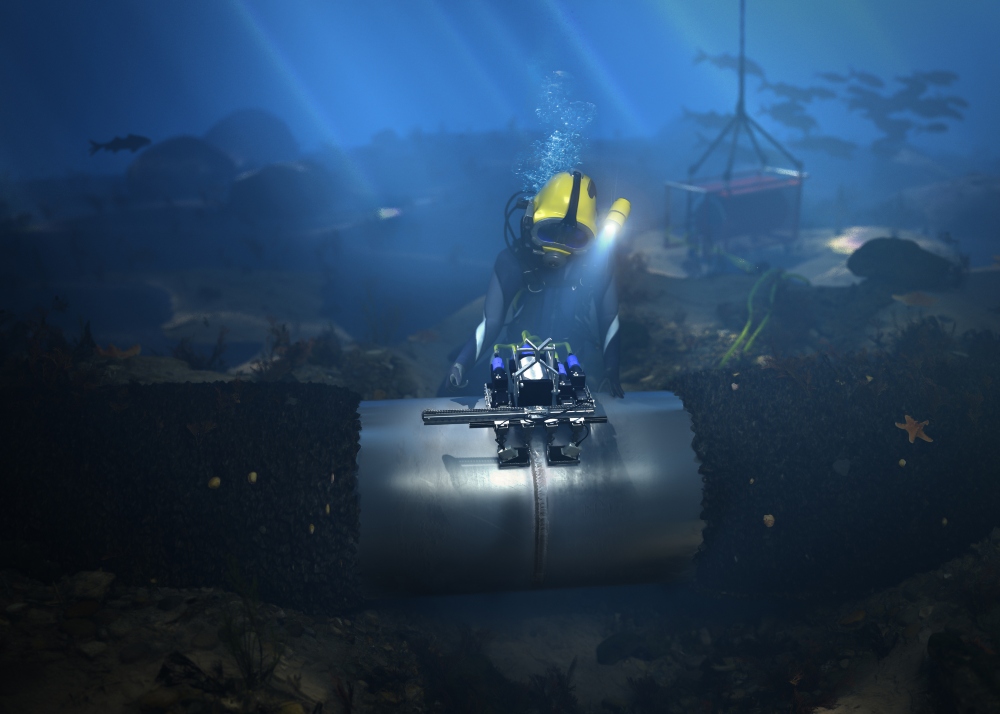

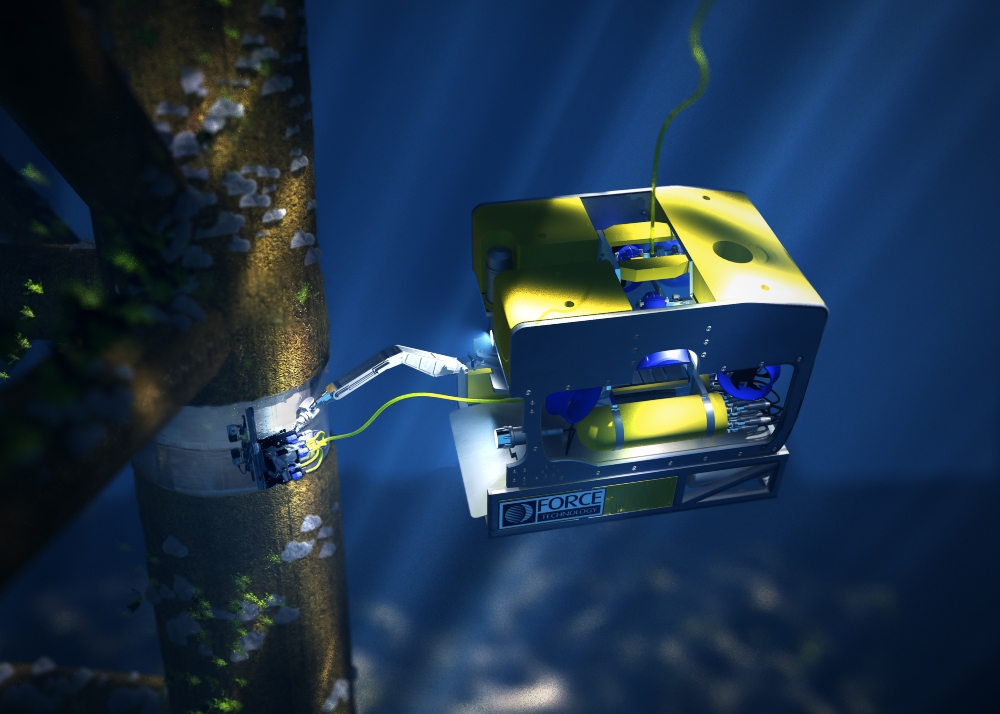

Technology like phased array allows the best possible better imaging of an inspected underwater component. It lets us access hard or even inaccessible areas, providing the best possible basis for tailoring maintenance, repair and asset life-extension solutions to customers' widely differing needs and assets. Automated reports help customers take better care of their assets and can contribute to documenting safety and compliance.

Modular subsea inspection system is easy to adapt and modify

All our tried and tested subsea inspection methods aim to give customers the information they need to make qualified, safe and financially sustainable decisions about their subsea assets. They include:

- Ultrasonic scanners inspect subsea pipelines and pipe geometry

Our numerous scanners controlled by our in-house developed P-scan systems for different purposes can be fitted for various geometries in all shapes and sizes, including pipe bends.

Key features:- Corrosion mapping of piping, both straight and bent pipes, ranging (but not limited to) from an outer diameter of 2" to 36"

- Precise ovality measurements for subsea piping interventions, hot taps and more (quali-fied accuracy of up to 0.2mm)

- Narrow access scanners (line-, ring-, segment- and sector scanners)

- All scanners can be fitted with eddy current testing probes to map surface-breaking flaws/imperfections on piping.

- Crack detection of subsea structures

Our P-Scan system effectively maps topography and inspects the subsea structures, pipelines and pipe geometry for cracks in the full volume of the material. It can be designed to follow complex weld geometry on nodes and has a high sensitivity towards imperfections.

- Cathodic protection (CP) survey of subsea structures and pipelines

The FiGS® CP survey is a field gradient sensor that measures current output from anodes, the current density of steels and current drain, and a potential profile of buried pipelines. It accurate-ly assesses conditions and detects even minor coating damages on exposed and buried pipe-lines and structures. The FiGS® CP survey provides an accurate image of the asset's condition, which allows for qualified decisions and substantial cost savings when considering life extension and anode replacement. This approach heavily increases the return on investment.

- Accurate fluid level measurements in buoyancy tanks

Using ultrasound helps accurately measure the water level inside buoyancy tanks. This is particularly useful if the built-in sensor is old, unstable or measures incorrectly.

- Flooded member detection (FMD)

This ultrasonic probe detects water ingress behind offshore steel structure members and sees flooding in structural members and buoyancy tanks. We provide various ultrasonic solutions for flooded member detection, typically tailored to each assignment depending on geometry and thickness.

Get in touch to find out how we can help you with your subsea inspection needs.

Services

Cathodic protection optimisation

/Service

We provide a wide range of cathodic protection (CP) services, incl. design, modelling & survey.

Structural monitoring

/Service

We provide management and control of the current status of pipelines, risers, structures and wells.

Subsea integrity management

/Service

Tying it all together, we offer integrity management of all your subsea assets.

Flexible riser monitoring

/Service

Increase safety & reduce risk through careful, real-time monitoring.

Retrofit & life extension of cathodic protection systems

/Service

We deliver highly cost-efficient retrofit solutions for life extension and repair purposes.

Cathodic protection of stainless steels

/Service

We offer cathodic protection (CP) for internal corrosion of stainless steels.

Corrosion and materials

/Service

We provide a variety of services related to preventing corrosion and maintaining material and technical integrity.