Analyse particle sizes and shapes with Computed Tomography (CT) technology

In materials science and quality control, understanding the sizes and shapes of particles plays a pivotal role across various industries.

Whether optimising powders for additive manufacturing, scrutinising grains of recycled plastics, ensuring the uniform distribution of active ingredients in pharmaceuticals, or delving into the intricacies of voids in injection-moulded plastics, precise particle analysis is the key to success.

Rich legacy of state-of-the-art particle characterisation methods

Our comprehensive approach encompasses traditional techniques such as sieving and dynamic light scattering (DLS) for particle size analysis, as well as advanced methods like small-angle X-ray scattering (SAXS) and small-angle neutron scattering (SANS).

Simultaneously analyse and 3D map up to 100,000 individual particles

We have recently embraced the cutting-edge capabilities of 3D X-ray computed tomography (CT) for particle analysis. What sets X-ray CT apart is its ability to simultaneously analyse up to 100,000 individual particles, delivering a comprehensive 3D mapping of each particle. This opens the door to an array of sophisticated analyses, including precise calculations of particle volume, surface area, Feret diameters (indicating the thickness of the flattest part of the particle), surface roughness, sphericity, orientation, and many more critical parameters.

Unwavering commitment to precision and excellence across all analyses

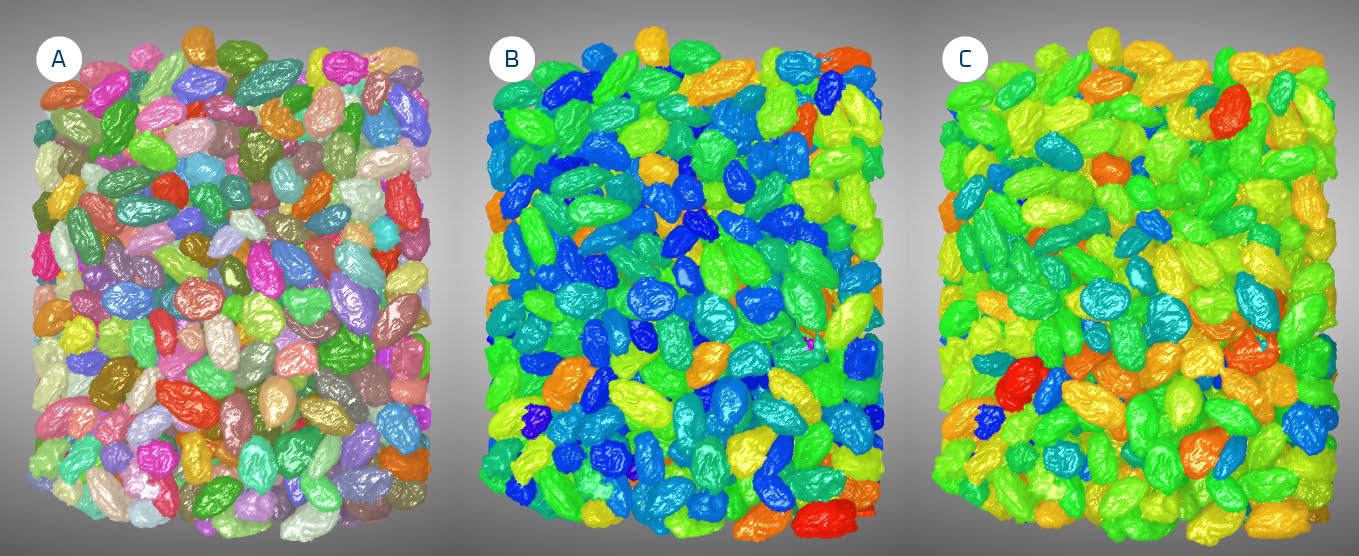

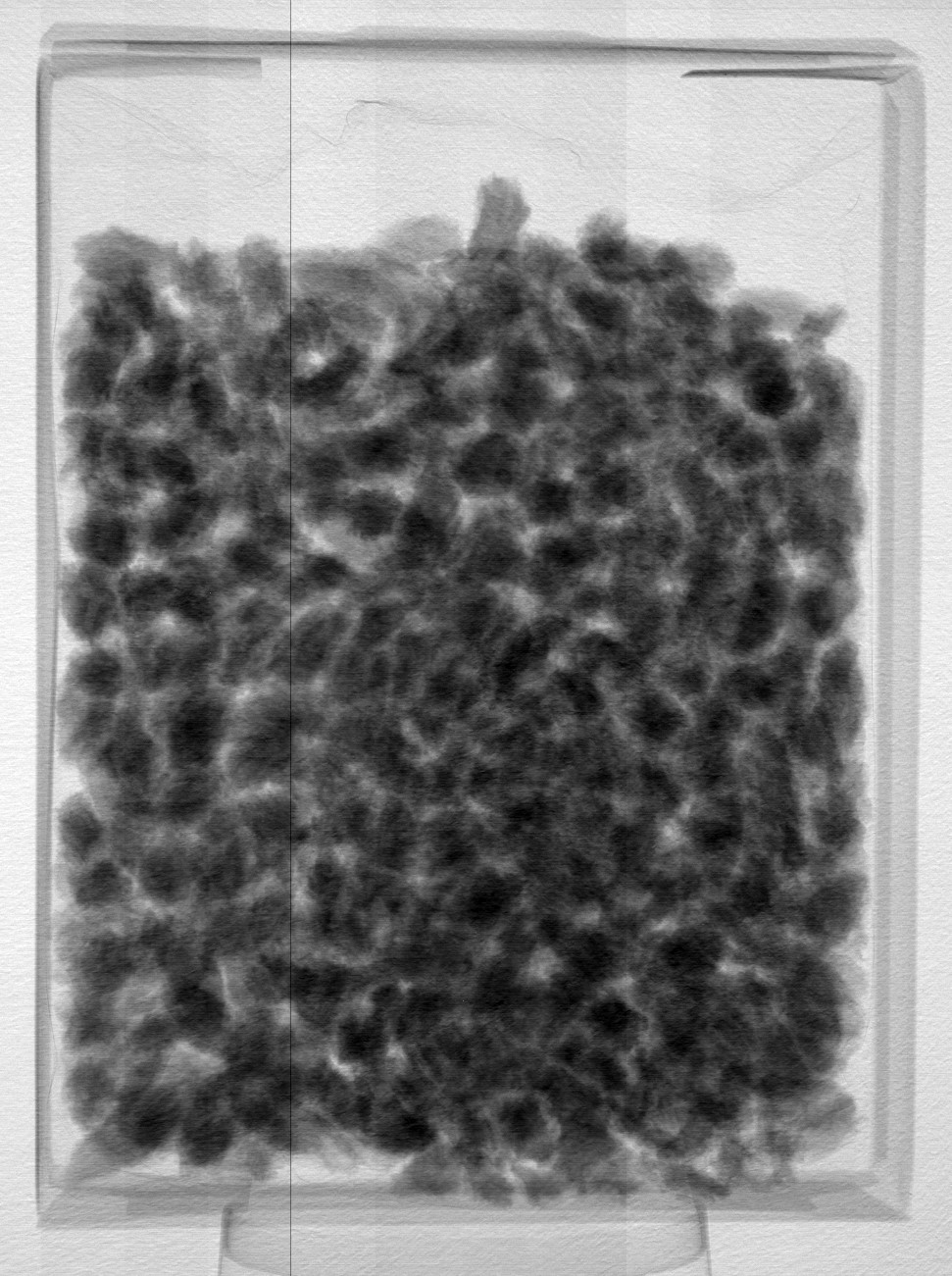

Due to our commitment to client confidentiality, we cannot showcase specific customer results. However, we can provide insights from an internal demonstration where we CT-scanned a sealed package of raisins. By digitally removing the packaging from the CT scan, we successfully identified and analysed a total of 684 individual raisins. Each raisin was identified individually, as demonstrated in Image (A), where each raisin is assigned a unique colour. Image (B) showcases the raisins colour-coded according to their volume. Image (C) depicts the raisins colour-coded based on their minimum Feret diameter – a metric that gauges the flatness of the raisins.

It is crucial to note that the analysis principles employed for raisins are equally applicable to particles of varying sizes, be it centimetre-sized raisins, millimetre-sized plastic granules, or micrometre-sized metal particles. While the CT scanner used for image acquisition may vary, the methodology and our unwavering commitment to precision and excellence remain consistent across all analyses.

Unravel the dimension and shape of any particle

If you have particles whose dimensions and shapes you need to unravel, we invite you to contact us today. Our expertise and cutting-edge technology are at your disposal to unlock the hidden insights within your materials. Let us help you elevate your particle analysis to new heights. If you have particles you want to know more about regarding their sizes and shapes, please contact Torben Haugaard Jensen.