Start-up ready to build facilities to store wind energy

Hyme Energy is building thermal energy storage, which will store electricity from renewable energy sources. A MADE project has helped the company to test whether the materials can stand the distance.

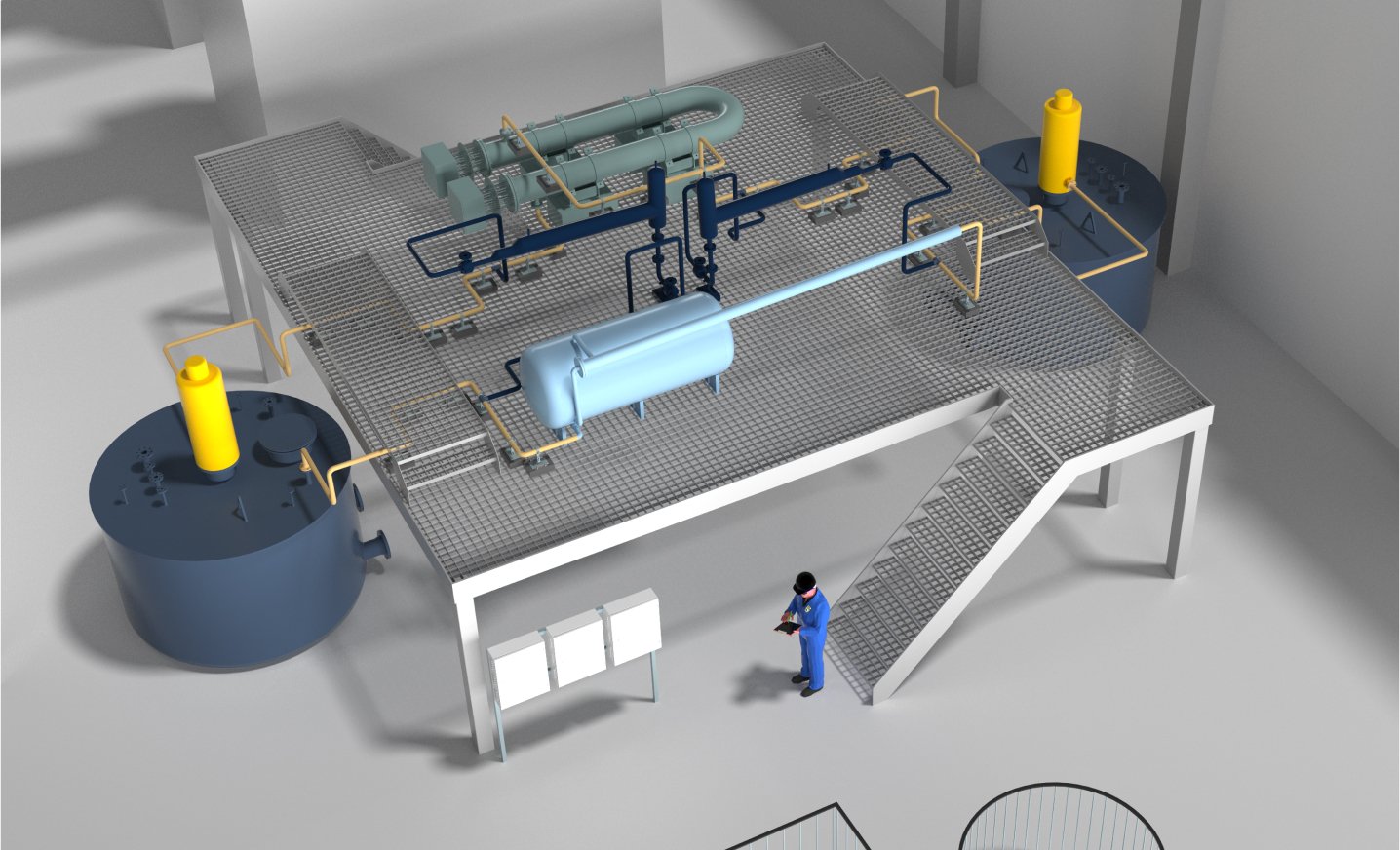

Hyme Energy's thermal energy storage system holds more than millions of litres of red-hot, highly corrosive sodium hydroxide, a substance better known as lye or caustic soda. It also holds green opportunities that extend far beyond its harsh chemistry.

The Copenhagen start-up's solution can store sustainably generated energy in sodium hydroxide as heat and convert it into steam when it is needed. The heat can be used directly in high-temperature industrial processes, as well as in electrical generation and co-generation.

Two projects seek to make Hyme's energy storage solution more mature. The first demonstration facility in Esbjerg will demonstrate the potential for storing wind and solar energy for later conversion into steam. A second, larger facility in Bornholm will determine whether the thermal energy storage system can also be used as a buffer for a co-generation plant, supplying steam for internal processes, electricity for main grid balancing, and heat for district heating customers.

Origins in Seaborg Technologies, a nuclear energy start-up

Hyme Energy has its origins in the perhaps more familiar Seaborg Technologies, a company developing a compact and safe nuclear reactor that is also based on liquid sodium hydroxide. This is possible because Seaborg Technologies has found a way to reduce the corrosive properties of sodium hydroxide. Despite that, the components in Hyme Energy's system will need to withstand extreme conditions.

In terms of material performance requirements, sodium hydroxide-based thermal energy storage facilities are on par with space rockets and Formula 1 racing cars.Carsten Jensen / FORCE Technology

“In terms of material performance requirements, sodium hydroxide-based thermal energy storage facilities are on par with space rockets and Formula 1 racing cars.” Carsten Jensen / Materials specialist at FORCE Technology

Mechanical challenges caused by fluctuating temperatures

Materials specialist Carsten Jensen has assisted Hyme Energy in a MADE Demonstration Project including input on material selection, the development of a test system, and collection of testing data.

Hyme Energy's goal is to be able to simulate how components and the system as a whole will perform over time.

"Our system undergoes thermal cycles involving heating from 350 degrees up to 700 degrees, then back down again. That causes the materials to expand and contract. If not properly designed, this mechanical challenge will be critical to the system's durability. For that reason, we need data on the properties of these materials for our simulation models," explains Jonathan Dam, a research and development engineer at Hyme Energy.

The start-up could have sourced this high-temperature data from international laboratories, but doing so would have been both slow and expensive. Instead, Hyme Energy devised a testing set-up inspired by the way the strength of high-tension cables is tested.

The testing set-up was created by suspending metal wires made of selected corrosion-resistant materials horizontally in an oven and heating the oven up to 700 degrees. Additionally, due to the materials' strength, weights were suspended from the wires on one end in order to measure how drastically they flexed in the heat, and how long it took them to do so.

Ready for their own oven

Jonathan Dam considers the MADE Demonstration Project a success that Hyme Energy will move forward with in its work.

"We were able to document that our testing set-up works and that we can collect data from it. Since we also need to test the corrosion resistance of our selected materials, we are now ready for our own oven, which will allow us to easily conduct even more material tests and collect data about their strength," he says, and adds:

"We're busy, so time and flexibility are crucial for us. We want to be a part of making the green transformation a reality as quickly as possible, and so we've set ambitious but not unrealistic goals."

We're busy, so time and flexibility are crucial for us. We want to be a part of making the green transformation a reality as quickly as possible, and so we've set ambitious but not unrealistic goals.Jonathan Dam / Hyme Energy

MADE DEMONSTATION PROJECTS

MADE Manufacturing Cluster - The Manufacturing Academy of Denmark offers demonstration projects:

With a MADE Demonstration Project, a small or medium-sized company may receive financial support of up to DKK 100,000 for solving a specific challenge in the company or testing a new technology in production.

Applications for demonstration projects in materials and manufacturing are accepted on an ongoing basis.

MADE Demonstration Projects are supported by the Danish Industry Foundation.