FEM analyses

FEM analysis provides the opportunity of ensuring a correctly designed structure avoiding the exposure to critical loads resulting in failure.

With the Finite Element Method (FEM), you get analyses of geometrically complicated structures and components and you may calculate many different problems and combinations of them.

FEM – Something for you?

FEM is a numerical analysis method, which is used more and more often to determine the stresses in structures. As structures become more complicated over time, it becomes harder to analyse according to the analytical methods. FEM is both versatile and applicable when the field of application of the analytical method is no longer sufficient.

- Analysis of stresses and deformations in complex geometries from a given load

- Sinking of floating items in liquids

- Heat diffusion and temperature variation through a structure

- Analysis of thermal stresses in thick-walled components.

We perform FEM analyses within many different segments including:

- Steel structures and steel joints

- Offshore industry

- Storage tanks

- Power plants

- Machines and machine elements

- Wind turbines

- Pressure vessels and tanks.

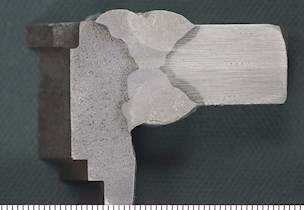

Examples of our experience with FEM

If you have a structure for which analytical methods are no longer sufficient, the FEM analysis may be the solution. With the FEM, we can analyse complicated structures and determine stresses, strains and deflections. In this way you can make sure that the structure fulfils legislative requirements and norms, and thus does not result in a breakdown.

These stresses can be assessed by a fracture mechanics analysis, and you can thus estimate whether the defect is critical with regard to remaining product life and brittle fracture.

We have experience in assessing the product life of components that are exposed to large temperature variations resulting in thermal stress. Here you can use the FEM analysis to determine the thermal stresses in a component, which may be applied to assess the service life of the component.

For strength analysis, fatigue, fracture mechanics analysis as well as thermally loaded components, we use current standards to ensure that your structure lives up to laws in force and other requirements and to safeguard against unexpected failure.

Services

Strength analysis of welded structures

Strength analysis of welded structures can protect you from failure and accidents.

Engineering critical assessment of welded structures

Is it safe to keep using a structure with flaws, without any risk of failure?

Lifetime assessment of wind turbine structures

Lifetime assessment helps you plan and avoid breakdowns in wind turbine towers and foundations.