X-ray measuring systems

An X-ray measuring system can contribute to optimising production and improving product quality. Furthermore, the system can assist in maximising resource utilisation by minimising errors and waste.

Improve quality and production

We have developed and installed many X-ray measuring systems that help secure optimal production, maximum production yield and optimal product quality. We configure the systems to fit and live up to your specific requirements.

Our X-ray measuring systems are built to optimise your production and product quality, reduce waste and consumption of raw materials and to document production.

We develop X-ray measuring systems for:

- production control in pipe production

- quality control of welds joining coils

- production and process control of materials or products moved on conveyer systems

- production control of flexible or rigid polymer based foam

Furthermore, we are OEM supplier of X-ray based core components and system parts to different industrial sectors.

Find a measuring system for your production

Below you can read more about our different X-ray measuring systems and download detailed product sheets. Please contact us, if you have any questions or inquiries.

In-line production control of pipes (TwinEye, TripleEye)

In-line quality control of welds joining coils (AWC)

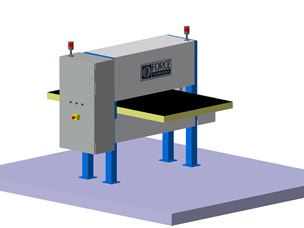

In-line production and process control (X-FORCE-Scan)

In-line inspection of flexible and rigid foam (PolyScan)

OEM supplier

If you want to know more, please contact us.

Downloads

Case

TwinEye X-ray measuring system monitors pipes in Brazil

Case

Innovative X-ray measuring system for the plastic pipe industry

Case

Another TwinEye X-ray measuring system installed at LOGSTOR

Case