Surface treatment & coatings

We provide complete assistance within surface treatment and coating, assuring that your asset is fully protected against corrosion throughout its service life.

We hold extensive experience and knowledge within corrosion and materials technology as well as inspection and maintenance planning. Our experts include some of the foremost specialists within corrosion protection, with published articles and books on the subject. This allows us to make qualified decisions regarding the choice of surface protection and coating.

We provide:

- Development of specifications within surface preparation and application of coatings (organic coatings, linings and metallic coatings (thermal spray coatings))

- Evaluation of coating specifications from suppliers

- Inspection and evaluation of results at shops or on-site by FROSIO qualified inspectors

- Failure investigations on-site or at in-house facilities

- Testing at in-house facilities

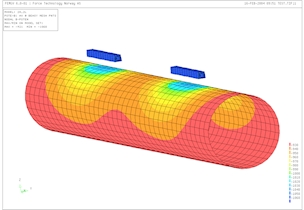

Surface treatment

Surface treatments are necessary to ensure a proper service life for all coating systems, and one of the most important steps is that the steel is completely clean prior to application of a coating system.

On large constructions, this is obtained by degreasing and washing the surface prior to abrasive blast-cleaning. This leaves the surface thoroughly cleaned with an anchor profile (surface roughness) providing proper adhesion of the coating system to the steel.

When dealing with maintenance of older constructions, abrasive blast cleaning may be a preferred method, but mechanical methods (Power Tool cleaning) and Ultra High Pressure Water Jetting are also common.

Coating

It is important to apply the coating system correctly and ensure that it has the correct number of coats and degree of thickness. Through our in-depth knowledge on how materials and coatings react, we can assist and advise on choice of coating types and coating thickness within environments from C1 to C5-I or C5-M (NS-EN ISO 12944) and NORSOK M-501.

Consultancy and Expertise

We offer years of experience and expertise, tailored to your specific needs. In addition to this, our variety of specialists within areas ranging from material technology, integrity management to monitoring, structural integrity and inspection, make us a preferred supplier and partner in offshore and land-based industry.

Do not hesitate to contact us if you would like to receive more information, or if you have any questions or inquiries.