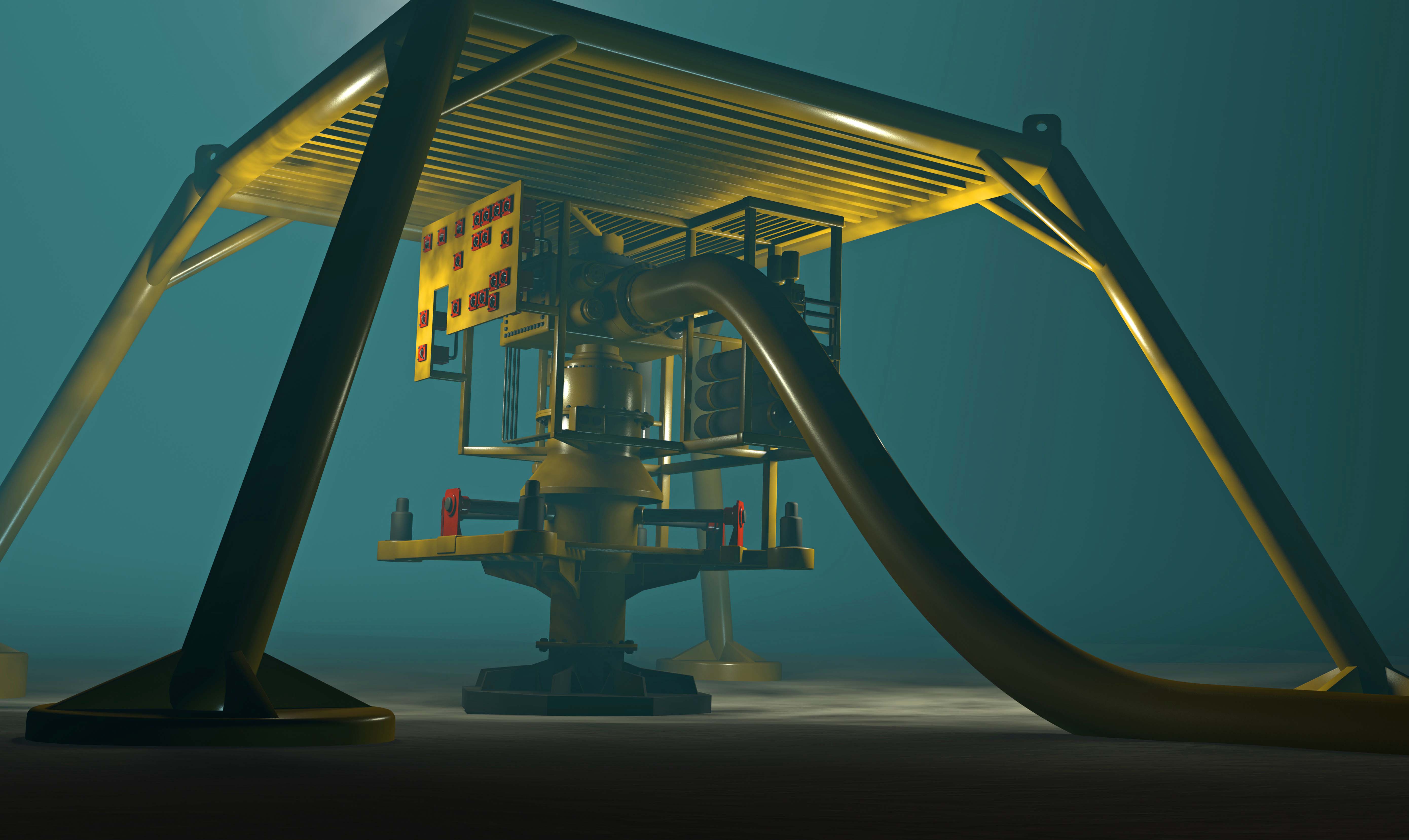

Flexible riser monitoring

Increase safety and reduce the risk and implications of damages or reduced service life through careful, real-time condition monitoring of your flexible riser and pipelines.

Real-time data for improved decision making

Since the early nineties, FORCE Technology has taken an active part in the development of condition monitoring systems for flexible risers. We offer three systems for monitoring flexible pipelines; vent gas monitoring (VGM), polymer coupon monitoring (PCM) and load & response monitoring.

Vent gas monitoring monitors vent gas rates, annulus pressure and annulus free volume, in order to determine the integrity of the flexible riser. The system looks at the main components of the flexible riser; such as the outer sheath, armour layer, the inner polymer sheath and the end-fitting. Sudden fluctuations suggest a change of integrity, which calls for action.

Polymer coupon monitoring monitors the integrity of the polymer sheath of the flexible riser. Coupons are placed inside the pipeline in order to expose them to the exact same conditions as the riser in question. The coupons are easily retrieved for examination with our patented method for evaluating polymer integrity.

Load & response monitoring registers motion within the flexible riser over time in order to estimate the level of fatigue. Several techniques may be used to determine the level of fatigue, but we typically monitor critical areas, such as the bend stiffener and sag bend, which are the most fatigue prone areas of the flexible riser.

More elaborate information about these systems is found below.Vent gas condition monitoring of offshore risers

The increased focus on health, safety and environment (HSE) in the offshore industry calls for pre-emptive actions in order to increase safety and minimise unnecessary stress on the environment.

The VGM system answers to that by supplying real-time and historical data on the condition of the flexible riser annulus, providing the operators with an opportunity to make qualified decisions based on actual measurements.

This is highly beneficial:

- at start-up

- during routine inspections to see that the riser is working according to specifications

- during the day to day normal operation

- in case of unplanned events

- when considering lifetime extension

- when planning for replacement.

Sudden changes in the annulus composition may suggest a breach in the outer sheath, in the inner liner or in the end fitting seal. Via composition data and monitoring of flow rates and volume directly, it is possible to detect the various types of breaches.

Polymer coupon condition monitoring of offshore risers

Flexible risers consist of several layers of polymer, one of which works as a sealing between the bore fluids and the surrounding layers. Keeping this layer intact and under control is crucial with regards to operational safety. The PCM system allows for continuous monitoring of the integrity of this layer, maintaining your security and control.

Unlike metal parts, the deterioration of plastic parts is difficult to assess. Typically, one would periodically replace the pipelines prior to the end of its expected service life. This often leads to unnecessary replacements, which is ineffective when considering the huge costs involved for such a replacement, in addition to profit-loss during unexpected shut-downs due to a pipeline integrity breach. The PCM system is intended to determine the remaining service life, as well as evaluating the performance characteristics of the sheath of a flexible riser, providing the operator with a powerful decision tool.

Exposure to bore fluids and bore environment ages the polymer, either chemically or physically. It has been found that the underlying ageing mechanism for PA-11 (a polyamide) is a chemical degradation of the polymer chains themselves. Therefore, monitoring the molecular weight of the polymer chain allows one to determine the exact rate of deterioration, and hence predict the remaining service life. This method has been developed and patented by FORCE Technology.

Load & response condition monitoring of offshore risers & pipelines

By installing inclinometers, accelerometers, strain gauges, temperature sensors and pressure gauges, the mechanical state of the riser can be monitored and analysed in real-time. The mechanical state may be influenced by local forces and bending moments, vibration, curvature, inclinations, accelerations and velocities on any axis. The combination and distribution of various sensors can be optimised to give a better estimation of any mechanical property of interest.

Through the implementation of a proper combinations of sensors, we are able to assess loads and calculate the accumulated fatigue damage and load history of near all structural elements in a riser or other mechanical structure.

Consultancy and Expertise

With FORCE Technology, you can always count on receiving expert consultancy throughout the process. Because of our extensive experience within monitoring systems in the offshore industry, we offer solutions that are tailored to your needs specifically.

Please contact us for more information or if you have any questions or inquiries.