A sustainable approach to salmon farming

A solution created in cooperation with AkvaDesign that eliminates the need for lice treatments and increases the growth rate and economy of offshore fish farming.

Each year, lice treatments cost the Norwegian aquaculture industry approximately NOK 500 billion in direct and indirect losses. Lice can survive at depths of up to 15 metres and inevitably infest open aquaculture systems. The long-time dream has therefore been to develop an environmentally friendly offshore solution, where there is more room for the growing industry.

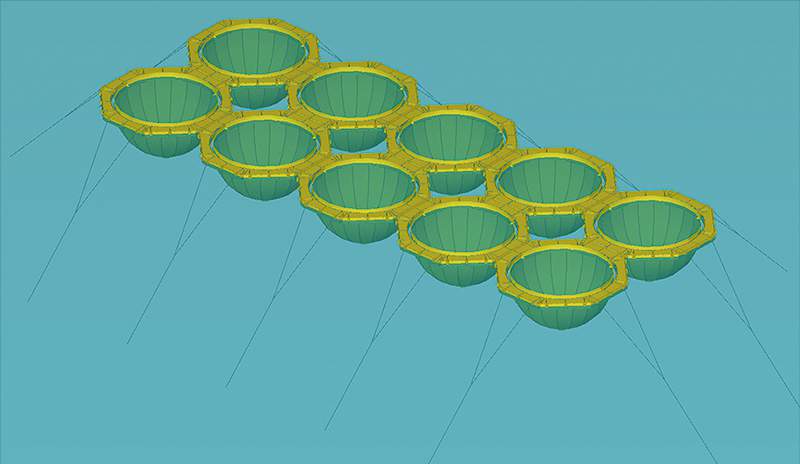

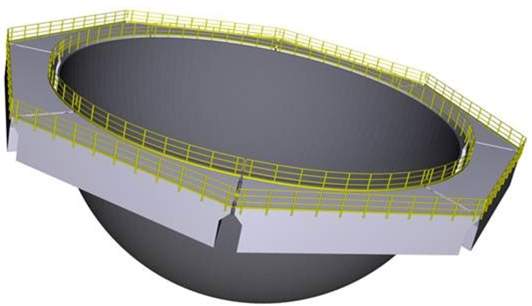

The Norwegian company AkvaDesign develops closed cages and has patented a new closed offshore system. AkvaDesign hired FORCE Technology Norway to complete the design of the closed system. They wanted cages that could be grouped together and could withstand waves of up to 2 metres. With the help of advanced hydrodynamic modelling, Jorunn Knive Hals, senior engineer, and Bogdan Iwanowski, principal engineer, took the lead on the final design: a wide floating collar in concrete with an impenetrable polyester skirt underneath. Nothing can get in, and nothing can get out.

Each cage has a diameter of 90 metres and can hold up to 6,000 m3. Fresh sea water is pumped up from a depth of 25 metres and the sludge from the bottom of the cages is used on land as fertiliser or biofuel. This results in salmon production with a minimal environmental footprint.

In trials with smaller models of the new design, the salmon stayed completely free of lice and the mortality rate fell to nearly 0%.