NS System reduces the trouble of equipment hunting as well as downtime with IoT

NS System is optimising its supply chain with a new IoT solution. QR codes save employees the trouble of hunting for equipment, while also revealing worn-out equipment and reducing downtime.

In Denmark, if you own a shirt, work uniform, or team jersey with a logo on it, chances are that it was printed at NS System in Frederikshavn. The company is among Northern Europe's largest textile printers and embroiderers, and the most widely used technique is screen printing. In this process, a logo, text, or pattern is first printed on special paper or foil, then transferred to a textile using a heated press. Printing is accomplished by forcing ink through a fine mesh stretched over a frame. With several production lines, there can be hundreds of frames in use at the same time, and as many as 20 - 30 frames on a single machine.

"We're a growing company, and we've been investing in efficiency and automation in recent years. Our employees pointed out that they wasted a lot of time searching for frames during print jobs," says Niels Rask, executive director at NS System.

NS System has a total of about 350 screen printing frames. Each one has its place in a rack, where you can flip through them rather like posters in a poster shop. But whenever a frame was put back in the wrong place (or not at all), a time-wasting hunt for the frame began.

Rejecting RFID

NS System brought the weakest link in the company's supply chain to MADE (the Manufacturing Academy of Denmark), where FORCE Technology, a GTS institute, offered its assistance in finding a solution. Adding an RFID chip to each frame was among the initial options considered, but FORCE Technology determined that RFID chips could be damaged by the forces that frames are subjected to during a busy day of printing, and they require batteries that would eventually need changing. If the RFID chip on a frame is dead, an RFID reader cannot detect it. This issue does not exist with QR codes, which can be scanned as long as they are visible to a camera and readable.

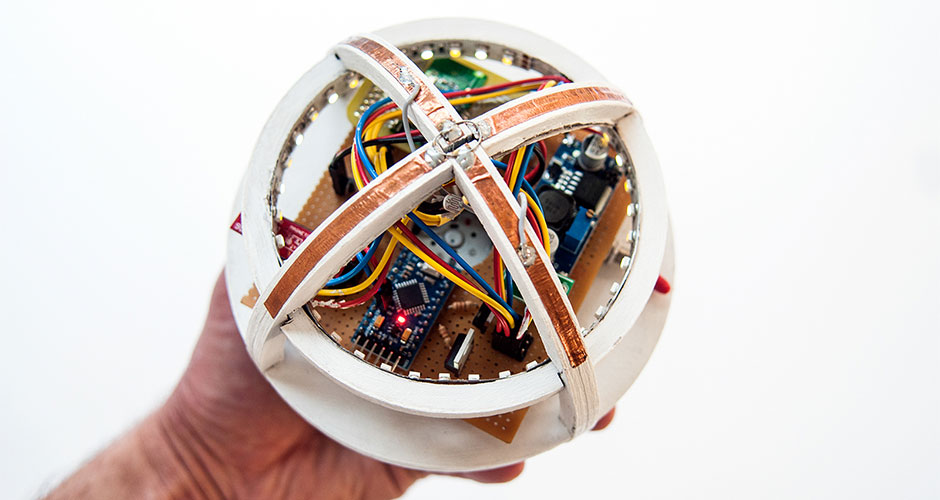

Consequently, FORCE Technology recommended and developed an IoT solution with QR codes for NS System. The company is now in the process of integrating a solution which assigns specific QR codes and frames to each order number, reserving those frames for that job. A fixed camera continuously scans the QR codes on the frames in the racks, and since each frame also has a unique number, the production management system can instruct an employee to use frame 27 in rack 4, for example.

"It's much more efficient than before. When fully operational, it will save us three or four man-hours per shift, halving the time spent finding frames," estimates Niels Rask.

QR codes provide production data

Not only will the solution reduce lead times - in the long term, it can also reduce downtime. Every frame is part of a cycle: after a print job, the mesh in the frame is washed and prepared for the next job. But the mesh only lasts for a certain number of cycles, and the usual way of identifying a worn-out mesh is by having it break during a print job, delaying the entire process.

"Because of that, we also installed a camera on the frame washer to scan the QR codes there. That way, we can count the number of washes a frame has gone through and collect data on how many cycles a mesh is good for. The idea is that an employee can use this data to decide which jobs a frame can be used on as its mesh becomes worn. Eventually, the frame can be thrown away before the mesh has a chance to break during a print job," Rask explains. He has also come up with more applications for the IoT solution using QR codes:

"We also have future plans for MIRs [mobile industrial robots], which will use the QR codes to retrieve used frames and load them into the frame washer."

NS System's director looks forward to continuing this collaboration with FORCE Technology.

"While the pandemic has caused some difficulties, it's been wonderful to work with them. They really know what they're doing, and they explained to us the pros and cons of using RFID and QR codes. The project is really important and relevant to us, and the solution we got works perfectly for us," says Rask.

Facility