FORCENSE Wellhead Monitoring

Using state of the art sensors, direct and indirect measurements with FORCENSE technology, we have provided customers with real time monitoring data from subsea wellheads for more than a decade.

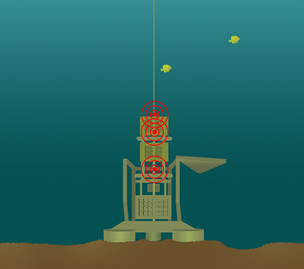

During the past 10 years FORCE Technology has provided customers with real time data of loads going into the subsea wellhead from the drilling rig’s BOP and riser system. We measure direct and indirect loads, with the FORCENSETM sensor range, mounted on the riser, LMRP and BOP.

The steady flow of information is used to:

- align the riser and BOP to prevent wear on the drilling equipment by positioning the rig

- reduce the moments transferred into the wellhead by positioning the rig

- verify that BOP and riser excursions are within the operational window

- detect abnormal behavior in the wellhead

- do fatigue assessment based on the induced damage

Text continues below images.

Utilisation and accumulated wellhead fatigue from the connected marine riser and BOP, or workover riser and EDP, is an issue of concern since increased IOR from the wells depend on active well maintenance, and the fatigue damage limits the number of days such systems can be connected to the well, and the corresponding operational window.

The monitoring systems are used on new wells to capture the actual accumulated damage from day one, through the life of a well, and on old wells where the calculated remaining fatigue life is limited and the exposure must be watched continuously.

Online data, raw and processed, is available through the riser monitoring system and as dashboards in the cloud application showing bullseye views, time lines, trends and frequency content, live, available onshore and offshore, and mitigating actions can be performed before the situation becomes critical.