Non-contact cathodic protection (CP) with FiGS®

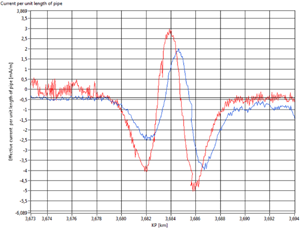

FORCE Technology Field Gradient Sensor, FiGS®, is a unique inspection tool that detects electric currents in seawater by measuring electric field gradients (FG).

Breaking barriers

FiGS® delivers highly accurate measurements with a resolution and detection level, surpassing all other field gradient sensors.

The accurate measurement of electric fields surrounding a subsea structure or pipeline provides us with the status of the cathodic protection (CP) system. It allows for identification of issues related to coating degradation and damage, as well as pinpointing anodes that are not working as intended and excessive CP drain to adjacent structures.

All of these issues can have a negative impact on the integrity of pipelines and structures. Knowing the exact condition of your CP system allows for an accurate assessment of remaining service life.

Limitations of standard contact CP

Periodic inspections using stab measurements are the current practice for CP inspection. As opposed to a FiGS® survey, where one measure both the strength and direction of the electric fields, which tells you how hard the anodes are working, stab measurements comprises local measurements of the electrochemical potential only.

Accurate readings can only be obtained through direct contact with the anode or on bare metal, if available. The output will generally only provide information about the current status of a CP system. A large number of readings combined with CP modelling is typically required to be able estimate the future CP status of subsea assets.

Article continues under image.

Integrity management & life extension of subsea pipelines

The sensitivity of FiGS® enables the identification of corrosion issues and the CP status assessment of pipelines and subsea structures, even when these are buried. In combination with CP modelling, this enables more detailed predictions of the future development and remaining service life, thereby optimising the investment in subsea inspection and maintenance works.

Integrity management of flexibles

The design life of flexibles is limited by coating degradation and corrosion in the strain armor. FiGS® can detect exposed steel, resulting from coating damages at the flexible pipe. Due to the construction of a flexible pipe, a small coating damage may expose a much larger area of steel, because of the strain armor layout. Any findings from the FiGS® survey can be combined with CP computer modelling to evaluate the size of the damage.

Contact us or visit www.figs.no for more information.