Accurate survey of cathodic protection (CP) with AUVs possible with FiGS® technology

Subsea vehicles are shifting towards automation, with longer, and faster subsea surveys, avoiding heavy vessels and equipment required in an intervention with standard ROVs.

Solving new challenges

Autonomous Underwater Vehicles (AUV) are faster and fly high above the pipelines. Therefore, Cathodic Protection (CP) survey is perceived as a technology gap when conducting pipeline inspection with AUVs. FiGS®, our non-contact CP sensor, provides the solution for this challenge.

The unique design of FiGS® ensures that the readings are not influenced by reference cell drift and provides both strength and direction of the electric field, making filtration of noise fields from subsea vehicles far easier. Its sensitivity and lack of need of calibration or physical contact, makes FiGS® the only sensor suitable for AUVs.

Pipeline position

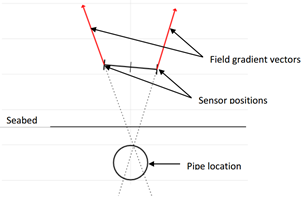

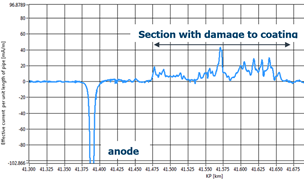

For pipeline surveys, two FiGS® sensors are positioned at an angle to triangulate the pipe. In areas with anodes or coating damages, where the intensity of the field gradient is higher, the measured field gradient vectors provide the direction from the sensors to the pipe.

During a survey, this feature can be used in real-time to track the pipeline, enabling the AUV to stay on track at all times.

More text following the images.

New possibilities with real-time data processing

The use of real-time data from FiGS®, with the right algorithms, makes the AUV “intelligent” when performing the survey. For instance, if the sensor recognises a finding during a survey, it could re-route the vehicle for a more detailed inspection of the segment where the finding was identified. This feature will bring more efficiency to the surveys, making sure that integrity threats are characterised with the information required for subsequent troubleshooting.

Integrity management & life extension of subsea pipelines

The sensitivity of FiGS® enables the identification of corrosion issues and the characterisation of cathodic protection (CP) system status. By combining FiGS® readings with CP modelling, we are able to estimate remaining life of CP systems and therefore optimise the investment in subsea inspection and maintenance works.

Feel free to contact us or visit www.figs.no for more information.