Looking to reduce the environmental footprint for offshore cathodic protection?

FORCE Technology is continuously striving to reduce our environmental footprint and support the industry in the green transition.

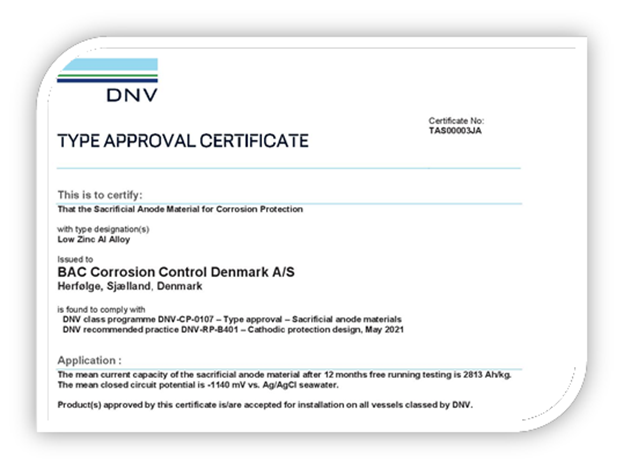

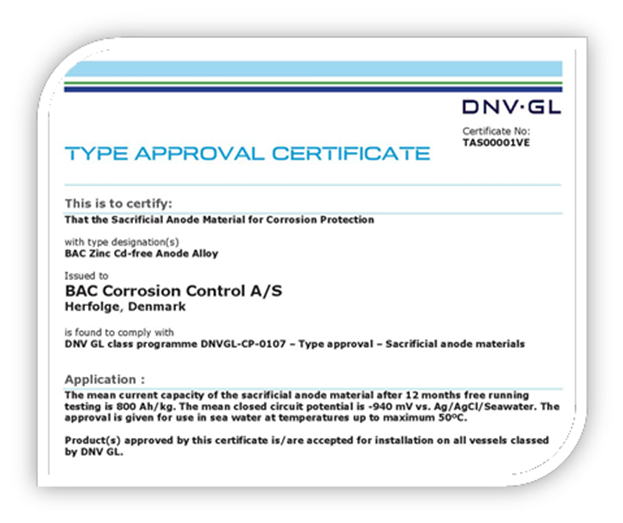

Through our alliance with BAC Corrosion Control AS, we offer solutions that significantly reduce the environmental footprint. We know that several countries have requirements for reduced use of anodes giving emission of toxic metals into the ocean and can now offer environmentally friendly galvanic anodes for all subsea assets, substantially reducing the release of toxic metals to sea. Two anode alloys have newly been certified - Aluminium anodes with 90% reduced Zinc content and Zinc anodes free of Cadmium. In addition to substantially lower content of toxic metals, the anodes are fabricated with furnaces powered by with renewable green energy further improving the environmental footprint.

Advancing environmental sustainability in offshore assets: Introducing FORCE Technology's eco-friendly galvanic anodes

The new alloys can of course be fitted onto all FORCE Technology/BAC standardized anode design for both construction and maintenance phase of asset life cycle. Our CP products also includes retrofit solutions, which are design to DNV and NORSOK requirements for offshore handling and deployment. This allows for immediate implementation without costly engineering, now providing an environmental contribution in addition to already being a cost-effective solution with short delivery times. Summarized, we see that our environmental galvanic anodes implies substantial contribution to both our clients and our own environmental footprint, for the operational life of offshore assets.

FORCE Technology is continuously striving to reduce our environmental footprint and support the industry in the green transition. Through 40 years we have been a global provider of Cathodic Protection services and always looking for ways to contribute to a better environment. For our business within corrosion protection this have e.g., be contributed by optimizing the number of galvanic anodes for the protection system – hence reducing the amount of anodes to a minimum. And now - together with BAC - we can offer further reduced environmental footprint by offering environmental friendly anodes. Please contact us for further discussions to give your company and the environment better conditions.