Offshore Wind Concepts for Cathodic Protection of monopiles at varying depths

FORCE Technology Norway was hired by leading offshore wind firm to test sustainable and cost-saving Cathodic Protection designs for huge monopiles in low resistivity areas, providing valuable results.

FORCE Technology Norway AS was selected by one of Europe's leading offshore wind operators to verify various concepts for Cathodic Protection of large monopiles in a low resistivity region.

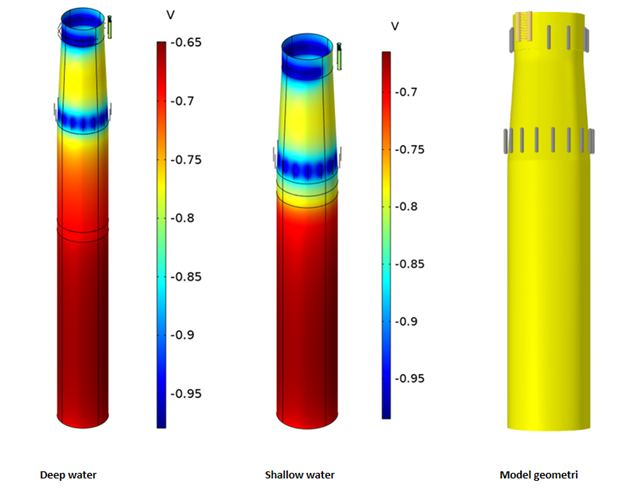

The work entailed evaluating concepts for cathodic protection of monopiles at varying depths, with combinations of protection from the Transition Piece, post-installed anode cages at the monopile and seabed anode sleds.

Designing Effective Protection for Offshore Wind Farms in High Seawater Resistivity

The main issue/challenge for providing adequate protection is the high seawater resistivity, which borders that of fresh water. This means that the throwing range of protective current from the anodes is greatly reduced, and the anode distribution becomes even more an issue as compared to more saline waters.

Modelling by our renowned SeaCorr/CP modelling tool was used to study the various concepts and determine the boundaries for each of them. Our unparalleled experience in design and modelling of offshore structures enabled fine-tuning of the initial concepts and provided the project team with a set of workable concepts for the development of the wind farm.