Subsea integrity management

We offer subsea integrity management through a multidisciplinary approach, with experts within CP, materials technology, structural engineering & monitoring, certification as well as customised subsea NDT solutions.

Cost reduction through improved service life

Subsea integrity management is a concept that is founded on a deep understanding of integrity management and subsea structures of all kinds. By utilising an integrity management approach to subsea operations, you can reduce the risk of unwanted episodes, improve the service life of your asset and keep costs at a minimum.

Our areas of expertise

- FiGS® CP survey of structures and pipelines (incl. buried)

- Structural engineering and structural monitoring

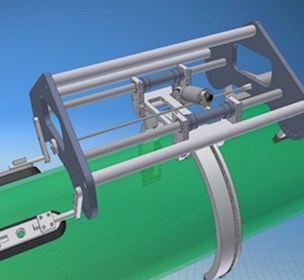

- Advanced inspection (subsea/topside)

- Cathodic protection of stainless steel

- CP design & modelling

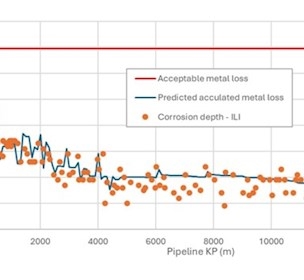

Risk based inspection

We use Risk Based Inspection (RBI) planning, which is a method for planning and inspection based on an assessment/analysis of probability and consequence of a component failure. By this systematic approach, the optimum inspection and monitoring schemes are determined and detailed inspection and monitoring plans are furnished.

Inspection planning encompasses various activities performed in order to optimise the use of inspection resources (cost effective), while at the same time ensuring the technical integrity of the asset. By targeting areas strategically based on an RBI, you acquire an inspection program that is cost-effective and ensures a safe and reliable operation.

Contact us today to find out how we can transform your subsea operations to run efficiently with less effort and resources.

Related content

Evolving subsea integrity in the North Sea

/Article

Pipeline integrity management & ANDT services

/Article

Ensure your subsea asset integrity with our advanced Automated Non-Destructive Testing solutions.

Pipeline integrity management with CorPos-ADMT & ANDT

/Article

Enhance pipeline integrity management with CorPos-ADTM & ANDT. Learn more today!

Subsea - a world of capabilities

/Page

We offer world class services catered to the subsea environment - from cathodic protection to monitoring as well as inspection.