Enhancing pipeline integrity management with advanced inspection technology

Boost pipeline integrity cutting-edge inspection tool. Using CorPos™ and ANDT, we ensure accurate corrosion detection and optimal maintenance planning for safer operations.

Pipelines form a critical part of our energy infrastructure, enabling the safe, continuous, and economical transportation of oil and gas. Their proper operation is essential for maintaining a company's export capabilities, which is why pipeline integrity management is such an integral aspect of downstream operations and maintenance in the offshore energy sector.

Pipeline integrity management involves identifying vulnerable spots along the pipeline susceptible to corrosion and forecasting corrosion over time to predict potential failures. At FORCE Technology, we have developed state-of-the-art tools and software to enhance pipeline integrity management, combining advanced inspection technologies with sophisticated corrosion simulation software.

In-house developed software and tools

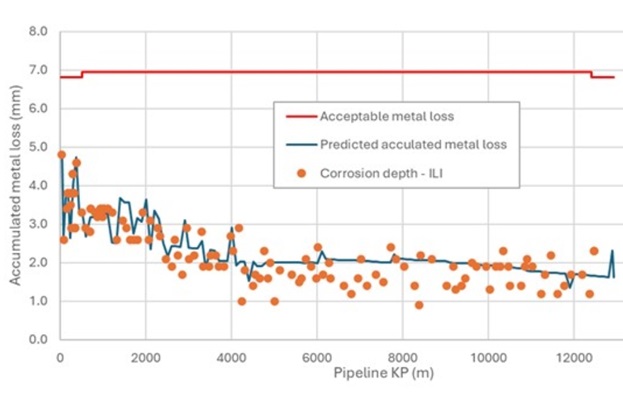

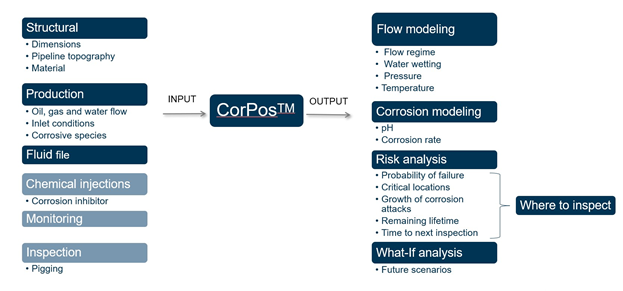

One of our key innovations is the CorPos™ software tool. CorPos™ assesses the corrosion profiles of entire pipelines, integrating modelling with monitoring and inspection data. This approach enhances safety control by providing comprehensive data on: Actual corrosion risk situation, risk status (maximum corrosion depth vs. acceptable corrosion depth), remaining lifetime (e.g., re-qualification/life extension of the pipeline), optimum time for the next inspection, requirements for chemical treatment (inhibition) and other KPIs, "What-If" scenarios, and advanced subsea inspection solutions.

In addition to our software, we offer intelligent and world-leading subsea inspection solutions capable of inspecting structures and pipelines of various geometries. Our latest Automated Non-Destructive Testing (ANDT) equipment represents a significant advancement in pipeline inspection technology. It is designed to offer unparalleled precision and efficiency in subsea inspections and combines high-resolution imaging with advanced data analysis, providing detailed assessments of pipeline conditions. The technology allows for the detection of minor coating damages and other defects that might otherwise go unnoticed, ensuring a thorough evaluation of the pipeline's integrity.

A powerful integrated integrity tool

The integration of CorPos™ with our ANDT equipment offers numerous benefits, making it a powerful tool for integrity management. Combining real-time data from ANDT inspections with the predictive capabilities of CorPos™ ensures a highly accurate assessment of a pipeline's current and future condition. This integration significantly reduces the risk of undetected corrosion, enhancing overall pipeline safety. Additionally, by providing precise information on corrosion and coating defects, this combined approach optimizes inspection schedules and maintenance activities, leading to reduced downtime, minimized operational disruptions, and substantial cost savings.

Furthermore, when analyzed through CorPos™, data gathered from ANDT inspections offers insights into timing for maintenance activities, helping to optimize maintenance planning. This proactive approach contributes to preventing pipeline failures and extends the operational life of infrastructure. Ultimately, the combination of these technologies allows for a holistic approach to comprehensive integrity management. It provides a complete picture of the pipeline's health, from current corrosion levels to future risk predictions, enabling informed decision-making and strategic planning.

Cutting-edge inspection technology

At FORCE Technology, we are committed to advancing pipeline integrity management through innovative solutions that combine cutting-edge inspection technology with advanced corrosion simulation software. Our integrated approach not only enhances the accuracy and efficiency of pipeline inspections but also contributes to safer and more economical subsea product transportation.

For technical personnel and managers seeking a robust integrity management tool, the combination of CorPos™ and our state-of-the-art ANDT equipment represents a significant leap forward in ensuring the long-term reliability and safety of subsea infrastructure.