Meeting the needs of safe downstream operations offshore Thailand

Recent oil spills in Thailand have highlighted the need for advanced subsea inspection technologies.

Southeast Asia has witnessed its share of oil spills that have negatively impacted the environment, local economies, and communities in recent years. These include the catastrophic 2013 Rayong spill in Thailand, where a ruptured undersea pipeline released 50,000 litres of crude oil onto the pristine beaches of Koh Samet.

More recently, in January 2022, the waters off Rayong Province were once again polluted when an undersea pipeline leaked 160,000 litters of crude oil into the Gulf of Thailand. The spill not only damaged the coastline but also reignited concerns about the safety and environmental practices of oil and gas operations in Southeast Asia.

Pipeline integrity

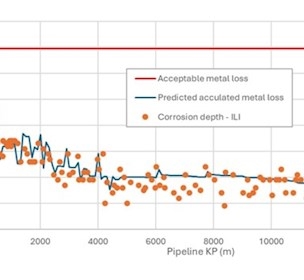

The incidents also highlight a critical issue: integrity of subsea infrastructure is vital to a region's prosperity. The importance of effective corrosion management and regular pipeline inspections has never been clearer. Cathodic Protection (CP) is one of the most vital methods used to safeguard pipelines from corrosion, yet its effectiveness depends heavily on routine and thorough inspections.

Advanced technologies for subsea inspection

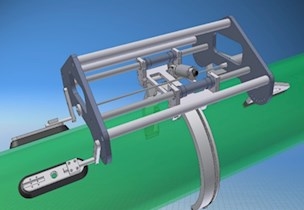

Advanced subsea inspection technologies, such as the highly sensitive Field Gradient Sensor (FiGS®) developed by FORCE Technology, are now at the forefront of enhancing the accuracy and efficiency of these inspections. Unlike traditional methods, FiGS® can detect very small coating damages and assess the remaining life of sacrificial anodes without the need for direct contact or excavation, making it a game-changer in subsea integrity management.

Current density

FiGS® detects coating defects in both exposed and buried pipelines without the need for excavation. Further, the accurate field gradient data measured by the high sensitivity sensors allows precise calculations of current density on coated and uncoated steel, as well as concrete structures, which is crucial for operators planning lifetime extensions or addressing anomalies in CP surveys. Currently, no other sensor can measure field gradients with the same accuracy and extent of analysis, making FiGS® indispensable for proactive maintenance and structural integrity.

In the wake of oil spills in Southeast Asia, it is crucial that national oil and gas operators adopt more proactive and technologically advanced approaches to pipeline maintenance. Doing so not only prevents environmental disasters but also ensures the long-term sustainability of the region’s vital energy infrastructure. FORCE Technology is on hand to help, with local partners ready to deliver cost-effective and insight generating data that could save the region from more pipeline leaks and the resulting challenges.

Contact us today for information on how to get FiGS® data in your region

Pipeline integrity solutions for Southeast Asia

/Article

Pipeline integrity management & ANDT services

/Article

Ensuring subsea integrity with FIGS in deep waters

/Article

FORCE Technology's FIGS and ROVs ensure subsea integrity with advanced cathodic protection.

Pipeline integrity management with CorPos-ADMT & ANDT

/Article

Enhance pipeline integrity management with CorPos-ADTM & ANDT. Learn more today!

Revolutionizing subsea inspection of CP systems

/Article

FiGS® offers non-contact assessments, boosting maintenance efficiency and extending CP systems' lifespan.