Inspection using drone technology

The optimal solution for inspecting hard-to-reach areas, both onshore and offshore.

An increasing number of companies today are using drone technology for visual inspection, providing a cost-effective and efficient way to access heights and otherwise inaccessible areas.

The advantages of drone technology

Drone technology offers a variety of advantages such as:- Quick overview and evaluation of the conditions

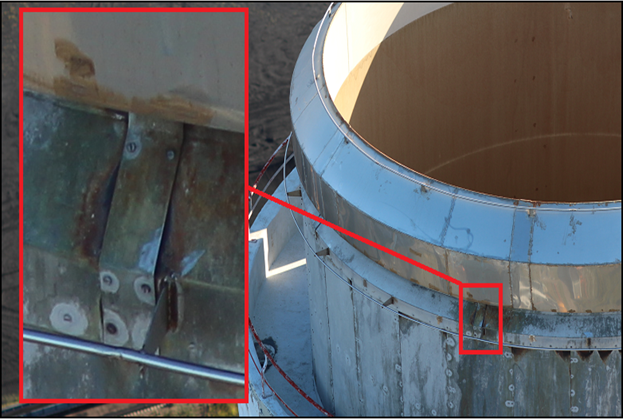

- Sharp and detailed photographs of defects

- Preventive maintenance planning and optimised production

- Access to hard to reach areas

- Reduced downtime

- High safety standards.

Typically, we recommend drone inspection for the following three categories:

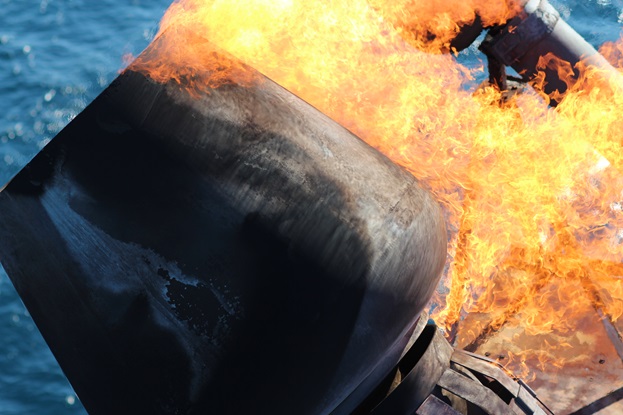

1. Offshore constructions

Offshore environments are tough and demanding, requiring minimal faults and production losses. For example, during a flare inspection on an oil-gas platform, drones capture image or thermographic data of the flare while production continues without disruption. The data collection occurs in a turbulent, flame-filled environment, with the drone, pilot, and inspectors safely distanced from the risk zone.2. Onshore constructions

Normally drones are restricted to flying at an altitude of 100 meters. FORCE Technology is authorised to carry out inspections higher than 100 meters.

An example is the inspection of a 225 meter chimney and masts at a power station, refinery or hydro power plant. Another area clearly suitable for drone inspection are bridges, irrespective of their being on land, connecting islands or spanning divisions in a landscape.

Additionally, drones are delivering good results with the increasingly taller wind turbines. In particular, leading edges, lightning receptors and nacelles are subjects for inspection. Here the drone collects high resolution pictures of potential defects, making it possible to plan repair work in detail as the data collected will help avoid unpleasant surprises during maintenance.

3. Confined spaces

Drones are increasingly used for inspections in confined spaces, such as boilers, fuel storage tanks, and other challenging environments. These inspections are invaluable when setting up scaffolding is too costly or time-consuming, or when physical access is too hazardous.

However, confined space inspections present challenges, such as poor lighting conditions, reflection of radio signals, and propeller turbulence. We tackle these issues by using powerful LED lights for optimal image quality and deploying specialized equipment and experienced pilots to predict areas with high turbulence risk.

The technical possibilities

Today, drones range from basic models capable of recording video and still images to advanced systems that can carry specialized data-collection equipment.

Advanced drones are particularly useful for measuring flue gas emissions or inspecting wind turbines, where thermographic cameras detect issues like delamination — internal composite layers separating beneath the surface of the wing.

We’ve also used thermographic cameras to inspect house roofs and electrical installations, identifying heat-related faults or defects.

Expert data analysis is crucial

While drone inspections are typically completed quickly, the bulk of the work lies in analyzing the data collected. Enlisting qualified experts for this analysis ensures that the full value of the inspection is realized.

Someone lacking the necessary qualified experience may overlook a critical defect or fault, possibly with fatal consequences. For instance, an inspection concerning a steel construction requires an expert metallurgist to analyse and interpret the collected data.

The inspection report, based on expert analysis, will categorize issues into red, yellow, and green priorities, according to the severity of the damage. If necessary, a service plan with recommendations for cost-effective improvements is included.

Drones for almost everything

As highlighted in this article, drones are particularly effective for offshore, onshore, and increasingly for confined space inspections. However, we always work closely with the client to determine if a drone inspection is the best choice based on the nature of the problem and the required data.

Given that a large part of drone inspections revolves around data and image analysis, it's essential that those conducting the analysis are experts in the field. Clients should request references from both the drone inspectors and the data analysts involved.

FORCE Technology's octocopter drone