CCUS: Carbon capture, utilization, and storage

CCUS, the capture and storage or utilization of CO2, is a crucial component in the green transition and a prerequisite for Denmark's goal of a 70% reduction in CO2 emissions by 2030 and climate neutrality by 2050.

CCUS involves capturing CO2 either from the atmosphere or from point sources such as incineration plants, production facilities, etc., with the aim of permanent storage underground (CCS) or utilization as a raw material to produce alternative fuels such as methanol or jet fuel in Power-to-X (CCU). Reliable and efficient collection of CO2 requires control over the processes and the physical conditions at the facilities.

The Danish subsoil is particularly suitable for CO2 storage, and the technologies to capture and store CO2 already exist, but there is a need to further develop, optimize, and scale them - just as our infrastructure needs to be expanded to support safe import, transport, storage, and utilization of CO2. Rapid expansion must not be based on solutions that later create new problems.

CCUS is largely described and regulated by the EU. It can be a comprehensive task to comply with all regulations and standards for a developer. Likewise, there are still some areas where standards are lacking. Overall, the challenges are to become familiar with the requirements from standards and legislation with minimal resource consumption. FORCE Technology offers services for the entire CCUS value chain in several areas, including:

Materials and corrosion

CO2, along with other factors such as the presence of impurities from flue gas, including sulfur compounds and moisture, and under conditions of high pressure and extreme temperatures, can pose a challenge for the materials used in, for example, pipes, tanks, valves, pumps, and wells. Therefore, it is crucial to choose the right materials already in the design phase, both for CO2 capture plants and for components to be used in facilities, transport, or storage of CO2.

You can get advice on and have materials tested to ensure they hold up once installed. We also test existing infrastructure to be used for, for example, the transport or storage of CO2.

In the event of a failure, you can also find out what went wrong to avoid it happening again.

Risk management

CO2 leaks can pose a significant personal hazard. Safety and risk management are therefore important to protect both people, equipment, and capital involved in either the development, operation, or handling of facilities or infrastructure. We work with a 360-degree approach and can support you with everything from HAZOP in the initial design phase to ensuring you have control over your operational risk management, as well as helping you with relevant documentation for authorities and other stakeholders.

Identify and manage your risks using, for example, a risk screening or by creating a list of inherent risks.

Measurement and documentation of emissions

With a CO2 capture plant, you need to be able to measure and document the captured amounts of CO2 as well as your emissions to the surroundings in the form of both CO2 and residual products from, for example, the use of amines for CO2 capture. Additionally, you should expect that buyers of captured CO2 will set quality requirements – that is, what and how many impurities are in the CO2. If the captured CO2 is used to offset taxes and quotas, additional documentation requirements are imposed – often with reference to EU regulations for CO2 quotas and CCS.

Ensure the content of emissions in flue gases and the purity of CO2, including the biogenic and fossil fraction, etc. Also, get help to ensure that the documentation meets the requirements that a verification will impose.

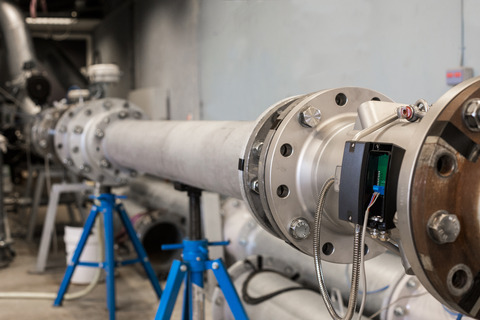

Metrology - Calibration of measuring instruments and measurement systems

Accurate measurement of CO2 is important, whether you need to document capture, storage, or for the sale and purchase of CO2. If you need to have your measuring instruments calibrated, we are available with knowledge and facilities. We are also available for verification of measurement systems or meters used for settlement measurement subject to requirements for independent verification.

We can also offer an objective and independent assessment of your equipment, for example, a supplier audit. We also offer an independent review of your maintenance systems, for example, against applicable requirements from EU regulations relevant to CO2 trading.

Consultancy on PED and CE marking

When handling CO2 either at facilities or in infrastructure, it must comply with requirements for pressure equipment according to the PED directive, and components and parts often need to be CE marked.

Get consultancy on which requirements your facility or equipment is subject to and how to handle documentation and certificates as well as the certification process, including installation control. If you need to have your facility certified, contact FORCE Certification.

Optimization of CO2 capture plants

Optimization of CO2 capture plants is important for both safe and economical operation and maintenance. We offer design optimization of the plant's components and configurations to ensure efficient CO2 capture, including liquid injectors, packing material, and flue gas piping. We analyze and test different tower configurations and absorber intercooling to find the best solutions.

After the completion of the plant, we can examine performance under different loads and adjust settings to optimize operating costs. We plan safe ventilation of CO2 and place sensors to detect leaks. After construction, we use a digital twin system to ensure cost-optimal operation and predict maintenance needs.

Knowledge sharing and innovation are crucial for CCUS

Knowledge sharing, networking, and innovation are crucial for developing and implementing CCUS technologies and establishing the ecosystem. Therefore, we participate in several projects, networks, etc., to contribute to this, including:

Green technologies

We also participate in a number of research and development projects (R&D) to provide the latest knowledge and technologies to our customers and society. Besides CCUS, we work on the following development projects.

Related content

Safe CO₂ capture: real-time emissions monitoring

/Case

Explore real-time emissions monitoring for CO₂ capture and CCUS at ARC’s waste-to-energy facility.

Documenting efficient carbon capture at Ammongas

/Case

Vital in fighting climate change, Ammongas proves the quality of their CO2 capture pilot plant.

What is carbon capture, and how does it work?

/Article

CO2 can be collected from combustion processes or the atmosphere via many different technologies.

For more information, contact

Lisbeth Brøde Jepsen

Sales and Business Development Manager

T: +45 30 58 99 66