Test your IoT devices yourself

Do-it-yourself test facilities provide many companies with the opportunity to carry out their own tests, which are developed in the IoT & Wireless Club.

The market for IoT is in rapid development and many manufacturers need to test their IoT solutions during product development in order to ensure that the products can also function in “real life”.

When we talk about IoT, it is easy to talk about all the new features that must be implemented with automatic maintenance, predictive maintenance, over-the-air firmware, and machine learning with big data. The challenge is simply that ensuring basic functionality is often forgotten. In this article we will describe a couple of the tests that can be carried out in IoT & Wireless Club’s do-it-yourself test facilities, and why we perform them.

IoT devices are often wireless and much of the functionality is dependent on the wireless connection and is directly dependent on the radiation of the antenna. Unfortunately, for most people it is not possible to test this radiation themselves at home, as it requires expensive equipment. Therefore, we have made this facility available to the club’s members, who can quickly set up a wireless device in the do-it-yourself facilities and measure the radiation.

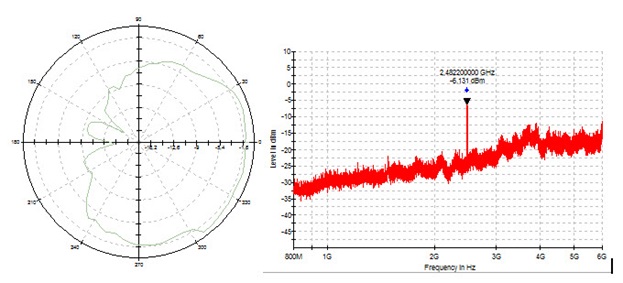

This radiation is normally measured in dBm and is a dB scale, which is relative to 1 mW. That is to say that a transmission power of 1 mW corresponds to a level of 0 dBm. 0.1 mW corresponds to -10 dBm, while 0.01 mW corresponds to -20 dBm. In a recently tested radio based on the nRF24 design, the radiation pattern shown in Figure 1 was measured, because the device had poor range. Here, it can be seen that the radiation from 30 over 0 to 240 degrees has “only” lost 3 dB, i.e. about half of the effect. In the other semicircle, on the other hand, approx. 10 dB has been lost, or the equivalent of 90 % of the effect.

Unfortunately, such results are not uncommon. A wireless unit was recently measured with an average attenuation of 20 dB. The challenge is that a well-designed module has roughly 0 dBm radiation power for this technology, but this is not mentioned in the datasheet because very few manufacturers can measure it. Even worse, most companies do not notice that they have been supplied with poor modules until they start receiving complaints from customers about poor range.

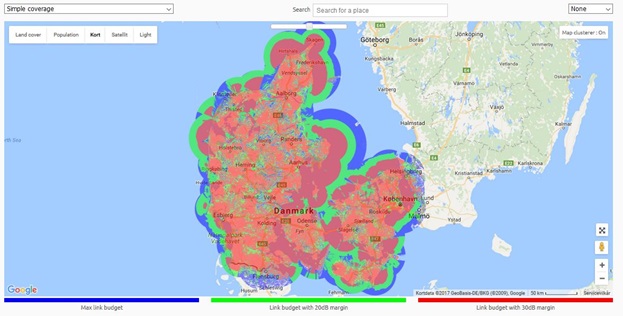

But why is it so important to measure the level of radiated power? Because it can reduce the coverage. This is why SIGFOX, for example, now requires companies to certify modules manufactured for its technology including that they have tested the transmitted power. Figure 2 shows the latest coverage map for SIGFOX coverage rolled out by IoT Denmark. It shows the level of coverage outdoors (in blue) for modems that have fulfilled the certification requirements. It is also possible to see the coverage (in green) when there is a reduction of 20 dB. This occurs if you are either indoors in an ordinary house or outdoors with a poorly implemented antenna. The difference is that you go from 98 % geographic coverage to 83 % demographic national coverage of Denmark, and the effect is even more drastic with other technologies. The advantage of do-it-yourself test is that you can pre-qualify your devices before they are sent for certification from SIGFOX.

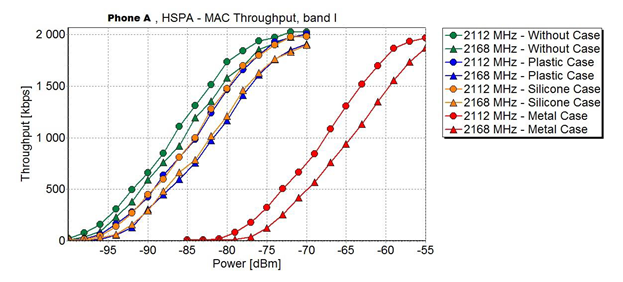

Another effect of a poor antenna is a reduction in the speed of the wireless transfer. Bluetest has produced a white paper that shows how much a mobile phone cover can reduce telephone coverage. Here (see figure 3) you can see that not only a metal cover reduces the transmission power by 20 dB, but also that it reduces the speed from 2000 kilobytes per second to approx. 150 kilobytes per second with a reference level of -75 dBm received power. You can also see that this reduction is considerably less, although still present, if you use a plastic cover instead of a metal cover. This is a scenario equivalent to including a radio module in your product, where you risk experiencing significantly reduced transmission strength.

The value this brings to a company can be seen for example in Danfoss, which uses it actively in its development process. By using the do-it-yourself test facilities, Danfoss achieves a more active participation in the test cycle and consequently more efficiency. If there are any problems or issues to be clarified during the do-it-yourself test process, experts are ready to help. The facilities offer the companies a great deal of flexibility, as they can perform the tests when it fits into their project process.

Do-it-yourself test is also a good way of reducing the expenses use on test and testing equipment, points out Jesper Bruhn Hansen, who highlights the advantages of joining the EMC Club or IoT and Wireless Club, where members gain access to some really useful basic knowledge.

A shared basic knowledge is essential if Denmark is to be at the forefront of IoT. FORCE Technology participates actively in international standardisation work, for example in ISO/IEC 30141 IoT reference architecture as well as international regulatory standards for regulatory requirements for EMC and radio parameters through ETSI and REDCA. All this knowledge, together with training in the use of facilities and knowledge sharing with central stakeholders in Denmark, is shared yearly at eight meetings, which are held both in Aarhus and Hørsholm. This ensures that we are speaking the same ‘language’ and can create a shared understanding of how to create innovative and robust IoT products.

IoT & Wireless Club consists of more than 40 companies and is therefore generally considered as being important to the development of hardware in Denmark. Rohde & Schwarz has therefore also chosen to make its brand new CMW290 communication tests available at the club’s do-it-yourself test facilities. These allow users to test GSM, GPRS, LTE, LTE-Advanced, LTE Cat 0 and 1, GPS, Bluetooth, WiFi and many more technologies. It will also allow Narrow-band IoT once this specification is completed (3GPP Release 13). It is also possible to measure the power consumption of the devices as a function of the communication. Bluetest from Sweden has also made its equipment available, in the form of a reverberation chamber to test radiation. This extends the existing facilities to enable the measurement of total radiated power, total received power, and data rate as a function of link attenuation. This chamber was used for example to produce the curves in Figure 2. Finally, work is underway to create virtual test environments where devices can be tested in the IoT ecosystem. This would take into account the connection of a device to a server, and that the data is part of a larger system, but would also consider the risk of hacking, which naturally must be tested too.

All in all, the do-it-yourself facilities have a total value of DKK 7.5 million and can thus save members from making substantial investments. The Nordic IoT centre also helps FORCE Technology supply the technical infrastructure for Denmark – a GTS obligation which we are delighted to fulfil.