Uncover the lifespan and robustness of LED lights

LED lights are finding their way into lighting products of all kinds. But what about the lifespan and robustness of the lighting source, and especially the power supply?

LED lights are rapidly making their way into all sorts of lighting products, and experience in handling light sources and power supplies is developing quickly. The lifespan and robustness of the power supply, in particular, are still an area of interest for research projects like LED Power Electronics to Last, which is financed by the Smart Energy Innovation Network (INNO-SE). However, the market surveillance body of the EU also have their eye on LED products and their approval. In this article, we share results and conclusions from the INNO-SE project and from the EU's market supervision.

LEDs and power supplies: Critical partners

LED light sources generally consist of 2 parts: The lighting element itself (the LED chip), and the power electronics (the driver) that provides power to the lighting element. The lighting element - the LED diodes - have reached a high level of quality after years of development, offering advantages in light output and durability. In principle, the driver is just a switched mode power supply, capable of providing appropriate power to the lighting element. The result is a very high ratio of light output per watt. In addition to the challenge of maintaining spectral properties and light output, another challenge lies in making the power supply last for a two-digit number of years.Technological changes in lighting sources also affect the technical requirements in (e.g.) EMC and Electrical Safety standards. Along with the mechanical-, thermal-, and humidity-related conditions in which a product is used, electrical conditions also influence the lifespan of a product. In recent years, this influence has been looked at under a magnifying glass, since LED lights do not behave identically to earlier light sources, such as incandescent and discharge lamps.

Power supply and the power grid

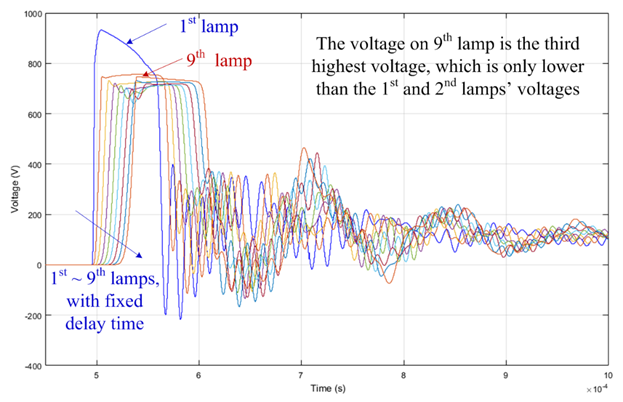

Voltage surges in the power grid were discussed in earlier articles as a potential risk factor for LED lighting equipment. This risk always exists, though the LED Power Electronics to Last project has shown that power quality logging campaigns in Denmark show a very moderate rate of occurrence of voltage surges. The project has also examined whether the specific installation conditions of street lighting can be considered to represent a special risk, since the power grid consists of open-air power lines which, from an electrical standpoint, can be considered transmission lines. AAU has created a model for a series of street lamps. Electrical simulations of the transient response for such a series of lamps were conducted, to determine whether or not resonances are created by transmission lines of a length of a kilometre or more, and the interaction with the reactive impedance in each street lamp's input filter.The detailed data is still being analysed, but the main conclusion can be seen in Figure 1. Such high transient voltage was applied, as to activate the varistors in each street lamp, resulting in limitation of the maximum voltage between phase and neutral to between 700 V and 900 V. We can see that the greatest voltage occurs across the first varistor in the series of lights, and that all other voltages are lower. If the transient is strong enough to destroy or burst the varistor (or the fuse) of the first lamp in the row, subsequent lamps in the series will still maintain their voltage within the limit established by the varistors. The oscillations that appear after the main cycle (i.e. after marker 6 on the time axis) are due to reflections on the transmission line. The reflections are not negligible, but for the line lengths used in real installations, it does not appear that serious voltage spikes capable of worsening the voltage conditions for individual lamps will occur. The topology, with lamps distributed along the transmission line consisting of open-air power lines, does not appear to represent a special risk of transient damage to lamps.

ADCO: The EU watchdog

The EU has a watchdog known as ADCO, which conducts ongoing market surveillance campaigns for electrical and electronic products. In late 2017, ADCO published a report on LED floodlights, covering working lights and point lighting for (e.g.) garages, workplaces, and similar locations. Report 7 is titled as follows: ”Report on the 7th Joint Cross-Border EMC/LVD Market Surveillance Campaign on LED Floodlights (2017)”. The report is available here.The products are not entirely of the same type as those covered by the corresponding report from 2015: “Report on the 4th Joint Cross-Border EMC Market Surveillance Campaign on LED lamps (2011)”. The report is available here.

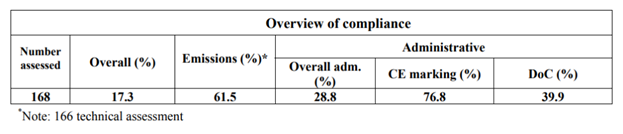

The LED products examined from 2011 to 2015 had a total success rate of 17.3 % (see Figure 2). During that period, the evaluations were carried out in accordance with the requirements for CE marking in EMC Directive 2004/108/EC. Conducted emissions were measured, and the complete technical documentation was inspected in relation to the directive's requirements. The errors and shortcomings identified varied widely in nature. Some products were missing a CE mark, while others contained directive- or standards-related errors or were missing information about the product itself or its manufacturer.

Safety included in latest inspection

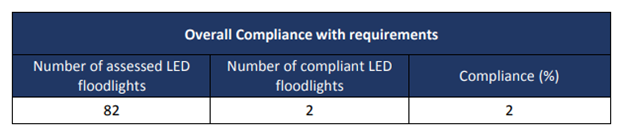

The latest inspection of LED floodlight products, from 2017, was expanded relative to earlier inspections to include both EMC requirements and Electrical Safety. The inspection was conducted following the same (old) EMC Directive 2004/108/EC, and the old LV Directive 2006/95/EC. Thus, the newer directives and their expanded documentation requirements for products and manufacturers were not used. The corresponding new directives in force today are 2014/30/EU and 2014/35/EU, respectively.The overall conclusion from the latest inspection can be seen in Figure 3.

Right away, things look bad. However, there are many finer details to the report, so we recommend reading the specific circumstances of each investigation to be able to compare and evaluate the more detailed conclusions.

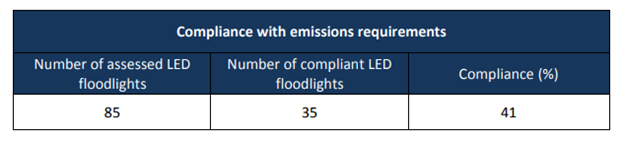

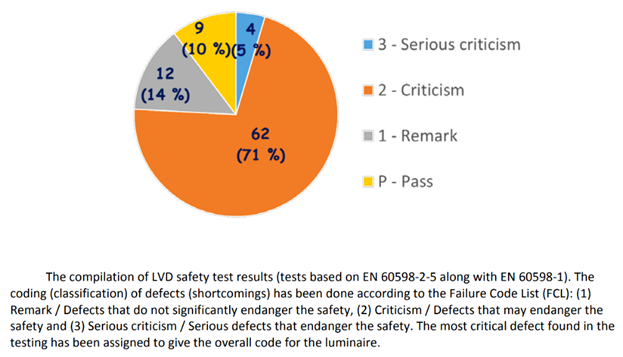

The newest inspection from 2017 has a somewhat different conclusion for each of the two technical areas, EMC and Safety. The report provides sub-conclusions for EMC emission requirements (see Figure 4) and for Electrical Safety requirements. Results are also provided in the areas of DoC (Declarations of Conformity), product marking, and Electrical Safety parameters, such as the risk of electric shock, creepage distances, and wiring. Note that 76 % of the products displayed safety-related defects categorised as "Criticism" or "Serious criticism" (see Figure 5).

Comprehensive EU requirements: Now with revisions!

Due to the expanded scope of the latest market surveillance campaign, it is difficult to make direct comparisons between the two campaigns. However, one common point between the two is the proportion of manufacturers from outside Europe. Only 5–7 % of the sampled products were produced by EU based manufacturers. Nonetheless, the reports show that European manufacturers generally do not perform any better than the others as far as compliance with CE marking requirements is concerned. We can conclude that it is clearly difficult to navigate the various twists and turns of the comprehensive regulations. In practice, even more requirements are often added, when directives and technical standards are updated. Rarely are requirements eliminated or simplified, despite that possibly being the intention.

As mentioned, the directive-imposed requirements for EMC and Electrical Safety have changed since the conclusion of the two reports. More weight is now given to documentation of traceability from product to manufacturer. The EU Commission wishes to be able to establish the origin of products that could cause problems on the European market. For that reason, the new directives include requirements for manufacturers, importers, and distributors alike. The Commission's position is clearly that products without a documented origin will not be accepted on the market. Of course, they have to be identified and reported on the market, before authorities can demand that a product be recalled, or that the use of a dangerous product be prohibited.

LED is changing standards

Along with the new directive-imposed requirements, some EMC standards have also been updated. This includes, for example, the EMC product standard for lighting equipment, EN 55015:2018. Among the updates is a requirement for radiated emission in the 300–1000 MHz range.

The basic EMC standard for harmonic emission, EN 61000-3-2, is also being revised, and is expected to be approved in 2018. This last standard has been updated to take into account minimum power requirements, which will be lowered from 25 W to 5 W. This is done to impose requirements on LED lighting sources, which would otherwise be exempt from the harmonic emission requirements due to their low power consumption.

It can be difficult to keep track of developments in both directives and standards. Changes may be made on short notice. The best way to ensure your own products is documented, is to follow or participate in standardisation work, or to make use of the services of a recognised advisor with respect to the relevant directives.

Note that ADCO has also performed market research in other product categories, such as power supplies and induction cooking appliances.