Asset integrity management (AIM)

Combining experience in a variety of areas, we offer a systematic approach for asset integrity management.

What are the benefits of asset integrity management?

The most obvious advantages of utilising an asset integrity management approach are:

- Reduced risks

- Increased safety

- Increase reliability

- Improved environmental performances

At FORCE Technology Norway, we have a long history of providing asset integrity management. With our wide spectre of expert areas and scientific approach, we ensure that your asset is in the best hands. We use our combined experience to ensure optimal solutions in terms of operational stability, safety and cost effectiveness.

Our services within asset integrity management

We specialise within:

- Risk based inspection / assessment (RBI)

- Corrosion management

- Subsea inspection management

- Pipeline integrity management

- Well integrity management

- Structural integrity

- Advanced inspection (onshore / offshore and subsea)

- FORCENSETM monitoring (vibration / structure / corrosion)

Risk based inspection planning

We use Risk Based Inspection (RBI) planning, which is a method for planning and inspection based on an assessment / analysis of probability and consequence of a component failure. By this systematic approach, the optimum inspection and monitoring schemes are determined and detailed inspection and monitoring plans are furnished.

Inspection planning encompasses various activities performed in order to optimise the use of inspection resources (cost effective), while at the same time ensuring the technical integrity of the asset. By targeting areas strategically based on an RBI, you acquire an inspection program that is cost-effective and ensures a safe and reliable operation.

Asset corrosion management

A large amount of the unforeseen incidents that occur in process plants are related to corrosion and erosion. Corrosion management is therefore essential in order to maintain the integrity of the facility, increasing the level of safety as well as improving cost-efficiency.

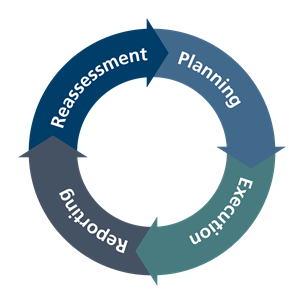

Corrosion management is a dynamic approach where we control and monitor an asset’s technical integrity related to material degradation such as corrosion, erosion, cracks and fatigue. It is a part of the overall management system, and is described in a Corrosion Management Strategy. A corrosion management strategy aims to define roles and responsibilities and ensure ownership, ensure focus on high risk system and identify barriers and Key Performance Indicators (KPI).Four steps of a continuous cycle:

- Planning: A detailed plan is established based on results from a risk assessment, and includes inspection, monitoring and mitigation programs.

- Execution: Implementation of defined and planned activities and programmes as well as identifying KPIs in order to measure critical parameters, and to ensure corrosion control.

- Reporting / measure: Measure and evaluate KPIs and data from inspection activities as well as monitoring and mitigation activities, and prepare status reports and improvements. We collect, compare and present data through a corrosion management information system.

- Improve: Review the effectiveness of the corrosion management programs, and improve the corrosion management activities and take necessary actions.

Subsea and pipeline inspection management

Pipelines represent a very important part of the energy infrastructure. Proper operation of the pipelines is critical to a company’s ability to export its assets.

We offer several solutions for these types of challenges (pipeline integrity management). This include among others; operational support, inspection planning, data analysis (e.g. pipeline degradation, remaining lifetime), corrosion modelling recommendations regarding corrosion and materials and advanced inspection / monitoring for subsea (e.g. vibration, field gradient sensor).

Well integrity management

Corrosion control for well operations is performed with a focus on health, safety and environmental requirements.

Costly work-over’s and loss of production can be avoided by implementing corrosion control for wells, using models and experience to understand the mechanisms driving corrosion. We offer, among others (well integrity management); corrosion monitoring, analysis and assessment of corrosion for wells (e.g. degradation of tubing, remaining lifetime of wells/tubing due to corrosion), in addition to addressing wellhead fatigue from drilling and workover operations.

Corrosion management

Our long experience within the area of materials technology improves our ability to identify critical technical factors affecting the safety of the installation throughout the operation. This concerns several types of structures and systems, including jackets, subsea structures, FPSOs, semi-subs, TLPs, risers, pipelines, subsea coolers, topside process systems, wells and onshore facilities.

Among other material related services within asset integrity management, we can assist with; material selection and verification, corrosion rate simulations and calculations, surface protection and CP management.

- Material selection/ verification

- Cathodic protection (CP)

- Coating and surface protection

- Welding consultancy/ Certification

- Laboratory services (testing and analysis)

- Failure assessment

Structural integrity management

We offer comprehensive consultancy services for concept development, design, verification, in-service and decommissioning of marine structures. This includes the detailed design analyses and analyses of the structures for all conditions.

We provide cost-effective assistance from the initial concept to final installation and subsequent maintenance and reanalysis, aiding in asset integrity management. The deliveries span over the following areas;

- Design and development of new structures

- Third party verification

- Reassessment

- Advanced engineering

- Analysis

- Simulation

- Design

- Reanalysis

- Modification

- Global and local analysis

- Verification

NDT inspection & advanced inspection (onshore / offshore / subsea)

We have experts within all standard NDT methods and hold a variety of equipment available for these types of inspections that support the asset integrity management process.

FORCE Technology performs NDT on a wide range of systems and components both onshore and offshore, and in addition we have extensive knowledge on the application and development of NDT methods for existing or new objects.

- NDT Inspection

- Advanced remote-automated subsea and topside inspection technology

- NDT certification of inspectors and equipment

- Procedures, verification and fabrication services

- Training (Inspection and methods)

- Destructive Testing

Monitoring services

FORCE Technology supplies in-house developed products and technology for measurement of strain, tension, motion and angular deflections, as well as vibrations and interfaces to other relevant sensors and systems. Systems have been delivered to major global operators. We provide monitoring services as part of asset integrity management for structures, wellhead, drilling/work-over risers, steel catenaries’ and flexible risers.

- Sophisticated Data acquisitions online or Autonomous Data Storage

- ROV deployable system

- Dry installed systems

- Online fatigue analysis and complimentary engineering services

Maintenance management

FORCE Technology offers customised solutions that use the state of the art methodologies and special tools to ensure cost-effective maintenance. We provide a wide range of services within maintenance management:

- Development of maintenance, inspection, and monitoring philosophies and strategies

- Criticality analysis using Failure Mode, Effects, and Criticality Analysis (FMECA)

- Definition of preventive maintenance programs using a Reliability Centered Maintenance (RCM) assessment

- Maintenance/inspection data analysis and reassessment of maintenance plans

- Specification and control of KPIs to ensure an effective maintenance management with a continuous improvement process

- Provide/develop data management tools and condition reporting systems to manage inspection, maintenance and condition monitoring information