Design and validation of efficient ventilation systems using CFD

Use of CFD in creation of safe conditions, both within industrial and residential spaces.

Promotion of safe conditions

Proper heating, ventilation and air conditioning (HVAC) systems play an important role in the creation of safe conditions, both within industrial and residential spaces.

These systems are necessary to provide individuals with air conditions that are humanly comfortable to withstand. Also, they are required to comply with safety regulations that consider detailed factors, dependent on the purpose of each building or single room.

Is ventilation really necessary?

Doing a detailed ventilation study at the design phase of any physical space, will contribute to:

- Ensure high air quality and a comfortable environment for users of the room or building.

- Prevent suboptimal and even dangerous room temperatures.

- Prevent undesired draughts.

- Prevent poor hygiene and infections.

- Prevent health issues due to inhalation of poisonous gases.

- Validate that the chosen size of HVAC systems fits the specific need.

- Reduce energy requirements, avoiding excessive power usage.

- Prevent damage of machinery or equipment.

- Minimize risk of fire, through controlled containment and spreading.

In the pharmaceutical and food industry, ventilation is especially relevant since faulty airing may lead to serious health issues not only directly affecting the employees, but also the consumers of the companies’ products.

At any industry where the presence of harmful gases is unavoidable, careful ventilation design and installation are required. However, at the design and construction stage of any type of building, ventilation systems must be considered a high priority, to warrant safe conditions at later stages.

How to achieve proper ventilation

Air temperature, velocity, humidity and in some applications, gas concentration, are closely monitored to assess the quality of a ventilation system. Each one of these variables needs to comply with specific regulations adapted to the purpose of different rooms and buildings.

The most common way to comply with these regulations is through the installation of heating, ventilation and air conditioning systems. However, in some cases natural ventilation can be enough. In order to assess if this is possible – or not – to find a suitable HVAC size, a ventilation study must be carried out.

Increase your ventilation system efficiency, through a detailed assessment using CFD

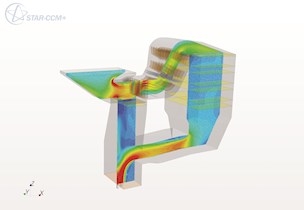

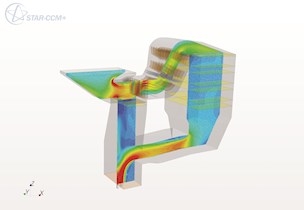

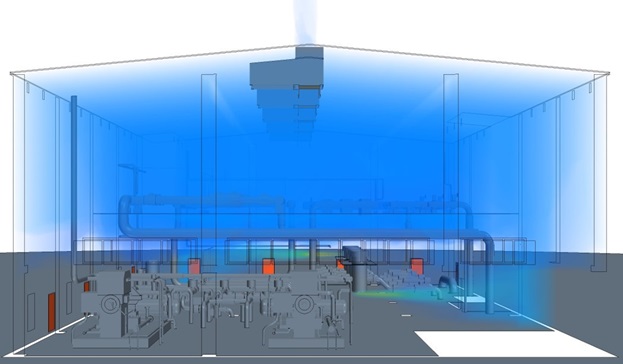

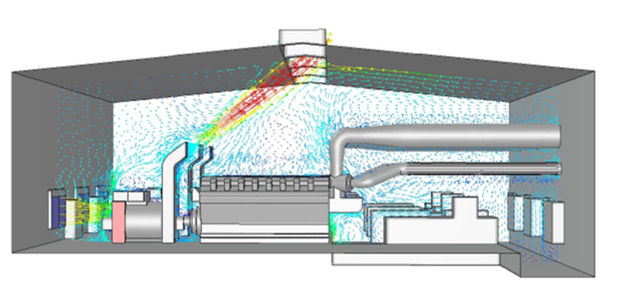

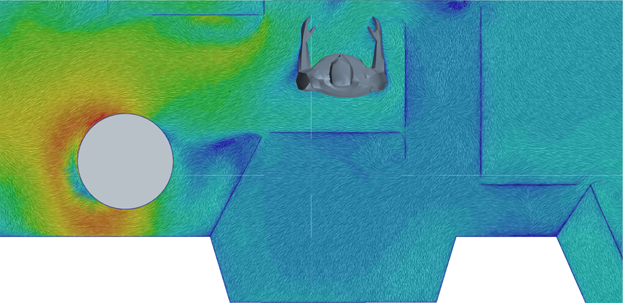

Computational Fluid Dynamics (CFD) can be used to assess whether a room complies with optimal ventilation, through quantification of critical variables.

Additionally, solutions tailored to specific rooms and conditions can easily be found using CFD. This ensures highly efficient operations of your ventilation systems, leading to prolonged lifetime and reduced costs.

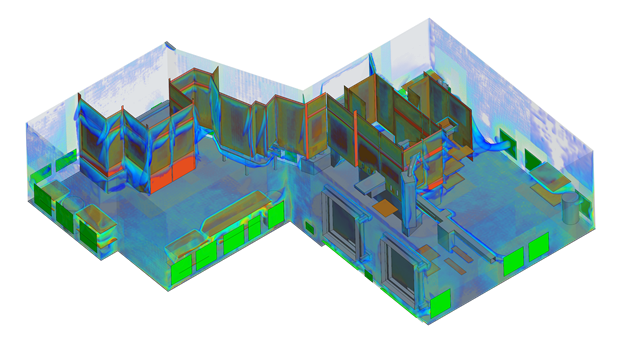

Full-scale 3D fluid dynamic numerical simulations allow for the modelling and complex geometries to obtain the values of all relevant variables at any point of the room. This cannot be done through analytical calculations, which mainly allow for obtaining average values. Average values are not necessarily representative of critical zones, potentially leading to incompliance of regulations and safety issues for the users inside the buildings.

The use of CFD permits obtaining the necessary information, removing the dependency of expensive and time-consuming tests.

Modelling of real conditions

Our 3D numerical models assess natural ventilation caused by external flows, as well as forced ventilation achieved through mechanical systems. In doing so, draught and air leakage quantification also come into play.

Regarding heat transfer, different heat sources and sinks (e.g. lighting gain, human gain, ground loss) are considered, as well as the different heat transfer methods (conduction, convection, radiation).

Draughts, flow vortices, local temperatures and solar radiation, are some of the most relevant phenomena affecting ventilation, and their detailed study without CFD – or expensive testing – is hardly possible.

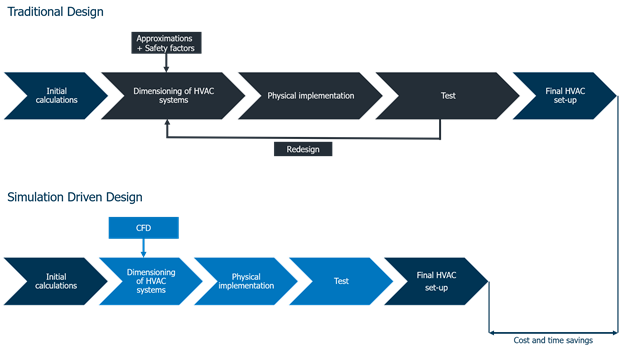

Time and cost reduction

When it comes to the design phase of the ventilation system for a room or building, replacing tests with high-quality numerical simulations has a direct contribution on time and cost reduction. Additionally, CFD can be used to estimate the optimal size of the HVAC system, which leads to a reduction of both capital and operating expenses.

It is highly encouraged to carry out a detailed CFD study before the installation of the HVAC system, to avoid re-dimensioning and re-installation costs caused by poor initial design – not to mention the downtime caused by these undesired procedures.

Easy start

At FORCE Technology, we conduct all the aforementioned tests for you – with the least amount of complications. In order for us to provide you with the optimal ventilation solutions based on our CFD simulations, we need:

- 2D drawings or 3D CAD of your desired object of study.

- Baseline configuration of natural and forced ventilation (if any).

- HVAC system (if any) data: flowrate, temperature, specific heat.