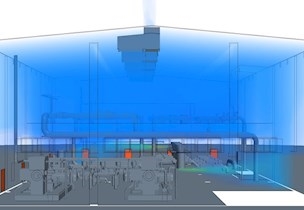

General design and flow consultancy for products and plants

We offer consultancy on design and installation of flow dynamics in order to maximise performance, energy efficiency and environmental load.

The highest performance of a plant in a wide range of processes and technologies can be closely coupled to the flow conditions. Designing and optimising flow movement requires detailed knowledge about the actual dynamic situation. FORCE technology has a wealth of experience in measuring this.

Physical experiments and numerical studies of flow

We offer a unique combination of physical experimentation and numerical analysis using both a mathematic model and our extensive practical experience. This ensures you can perfect the flow conditions in your plant or product by changing the design to obtain the optimal performance solution.

Services within flow optimisation

We can support you in the entire process from consultancy at the design stage through diagnostics and evaluation to on site optimisation.

Flow improvement is always performed in a close collaboration with the customer, as we need to integrate detailed specifics about your product as well as to consider other conditions besides the flow technology, such as production or application of the product. This is important in order for you to achieve a successful solution.

The successful outcome of flow analysis and optimisation of your product or production process may be:

- increased performance and efficiency

- reduced energy consumption

- maximising production rate

- minimised operational and maintenance costs

- reduced down time

- minimising damage, wear and erosion

- prolonged life time

- reduced emissions

- possibility of down sizing

- effect of upscaling

- reduced pressure loss.

Facilities

We have a long and wide experience in delivering flow-optimised solutions to the industry. Our consultancy services are based on a worldwide experience in industrial fluid dynamics, access to state-of-the-art software and hardware facilities together with sophisticated flow-measuring equipment and modern laboratory facilities.

To be able to solve our clients challenges involving complex mathematics, we develop and implement models using a specially developed CFD tool.

FAQ

-

What is computational fluid dynamics (CFD)?

Computational fluid dynamics (CFD) is a computer-based simulation method for fluid dynamics investigation. It is applied as a supplement or an alternative to experimental investigations and provides detailed prediction of flows.

Computational fluid dynamics makes it possible to simulate and describe flows that are complicated, expensive or impossible to study using experimental techniques.

A major advantage of using CFD is that information about the flow and pressure fields together with other related phenomena such as heat transfer, chemical reactions or multiphase flows features are obtained in the fully modelled geometry. This makes CFD an effective tool at the design stage as well as for optimisation and trouble shooting of existing installations. Once the CFD model has been set up, geometrical or operational changes can easily be implemented and tested.

For very complex flow challenges, where existing state of the art software possibilities are not sufficient, FORCE Technology has specialised in developing supplementary models to be able to solve your needs.

-

What is experimental fluid dynamics (EFD)?

Experimental fluid dynamics is a physical modelling method for flow investigation. An experimental model is constructed in either full-scale or model scale where the flow can be measured at specific points in the model.

This allows for precise interpretation of the flow under various conditions. This knowledge can be used in all kinds of test conditions, where precise knowledge is required.

The model set-up allows for supportive measurements sustaining the numerical investigation from computational fluid dynamics.

Furthermore, experimental fluid dynamics may be applied as the best option in specific cases where existing CFD models are not accurate enough or may require extremely long calculation time.

-

What is a theoretical flow investigation?

Theoretical flow investigation is a simplified and fast method of predicting flow of fluids. It is cost-effective and can be applied to standardised cases. The theoretical investigations are supported by our many years of experience in flow investigations.

The analysis may form basis for the computational and experimental methods.

The theoretical flow investigation provides knowledge about the flow, which ensures a more qualified point of departure for the computational and experimental methods. This may reduce cost and time for the overall investigation.