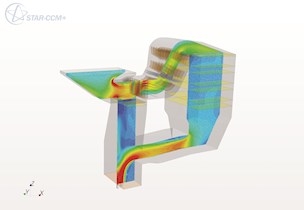

CFD combustion simulation and consultancy ensures efficient and environmentally friendly combustion

Computational fluid dynamics (CFD) simulation of your combustion processes gives you great financial savings and reduces downtime compared to tests on the plant itself.

The performance of a wide range of processes and engineering technology are closely coupled to the flow conditions in the plant. Designing good flow solutions requires detailed knowledge about the actual flow conditions, which we can establish.

Physical experiments and simulations to optimise combustion plant designs

We offer a unique combination of physical experiments and numerical investigations based on a theoretical foundation and our extensive experience. This gives you optimal knowledge about the flow conditions in your plant or product, and allows you to make the correct decision about where to change the design to obtain the optimal solution regarding performance, energy efficiency and environmental load.

Our services span from consultancy at the design stage through diagnostics and evaluation to optimisation of flow solutions. Flow optimisation is always performed in a close collaboration with the customer as we need to integrate detailed specifics about your product as well as to consider other conditions besides the flow technical issues, such as production or application of the product. This is important to ensure a successful solution.

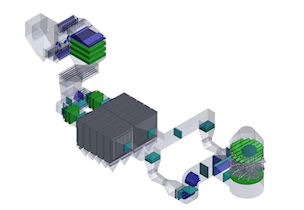

Design and retrofit of boiler and furnace solutions using CFD

We offer consultancy on design and optimisation of boilers and furnaces at the design stage as well as in retrofit situations. To gain detailed knowledge about the actual flow and combustion conditions in your plant, we apply computer simulations (CFD). This provides a strong platform for performance improvement regarding efficiency, emission control as well as reduction of risk of corrosion and other damage.

Fossil and new fuels

CFD has proven to be an effective tool for design of many different types of plants including

- coal fired plants

- biomass combustion plants

- waste- to-energy plants

- green fuels.

Based on the results of CFD analyses combined with our knowledge and long experience within combustion technology, we generate optimal solutions, resulting in improved performance, minimised emissions and enhanced service life of your plant.

Facilities

We have a long and wide experience delivering flow-optimised solutions to the industry. Our consultancy services are based on a worldwide experience in industrial fluid dynamics, access to state-of-the-art software and hardware facilities together with sophisticated flow-measuring equipment and modern laboratory facilities.

To be able to solve our clients’ challenges involving complex physics, we develop and implement additional models in the applied CFD tool.