Design and validation of efficient flue gas cleaning systems using CFD

Flue gas cleaning units are commonly used to discharge clean air into the atmosphere and comply with environmental regulations.

Compliance of environmental regulations

At FORCE Technology, we have extensive experience working with some of the most used technologies for this purpose.- NOx reduction: SCR and SNCR.

- SOx reduction: FGD and Scrubber.

- Dust Particles Separation: Cyclones, Bag Filters, ESP and WESP.

Flue gas cleaning efficiency

In order for these units to properly clean the gas, close attention must be paid to the efficiency at which they do so.

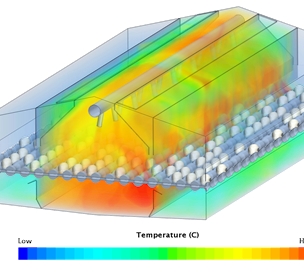

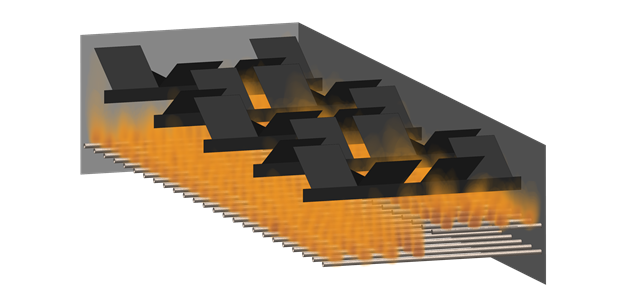

The efficiency of any flow dependent system is highly affected by the flow distribution inside of it. Poor flow distribution can lead to unit malfunctioning, since most internal processes are dependent on specific requirements, such as velocity or temperature optimal conditions. Inability of these processes to take place, will not only worsen the performance of a single unit, but it can also lead to strong repercussions in the performance of the entire system that it belongs to.

Flue gas cleaning units are no exception to this behavior. Improving the flow distribution inside the cleaning unit, allows necessary chemical reactions and heat transfer processes, to occur optimally. Optimal performance of these processes translates itself into better cleaning efficiency.

Increase your unit's efficiency

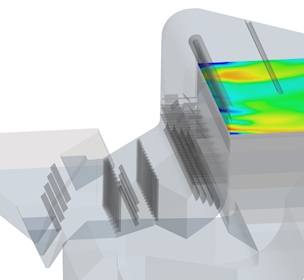

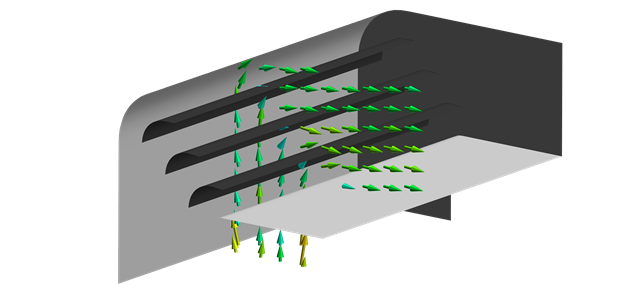

With more than 200 cases of experience we can optimise the flow distribution inside your flue gas cleaning unit, using our CFD (Computational Fluid Dynamics) tools and methods. Our solutions ensure not only high cleaning efficiency under all loads and operating conditions, but also optimal performance, extended lifetime and reduced operational cost of units, through:- Optimization of flow distribution

- Optimization of injection systems

- Improvement of mixing

- Reduction of pressure drop

- Minimising use of necessary cleaning substance

- Reduced risk of erosion

- Reduced risk of dust accumulation

- Minimised recirculation areas

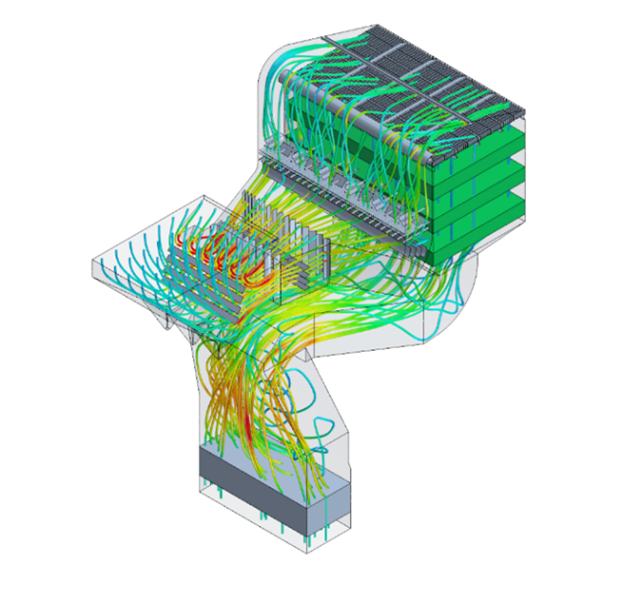

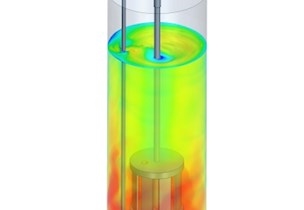

CFD analyses performed on full-scale 3D geometries

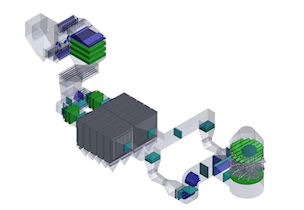

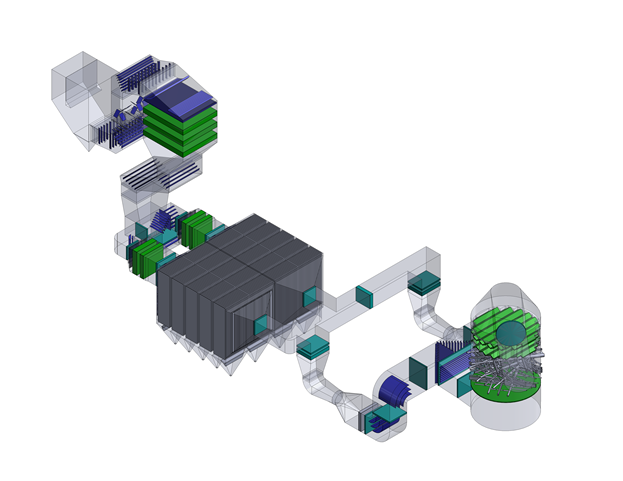

Our CFD analyses are performed on full-scale 3D geometries constructed based on CAD data, and modifications of the model regarding operating conditions, guide vanes and injection systems, can be easily implemented to obtain the best flow conditions possible.

We also provide services of manufacturing and testing of scaled-down flow models in our facilities. This means that you have the possibility to choose between a CFD only study, an EFD (Experimental Fluid Dynamics) only study, or a combination of both studies.

Manufacturing and installation simplicity

Our flow optimisation process covers design, placement and selection of the minimum amount of conditioning devices needed to properly distribute the flow.

To do so, the baseline case is evaluated, and flow optimization devices are designed accordingly, taking into account manufacturing and installation simplicity. Injection systems are also optimized upon request, as well as the geometrical re-design or even initial design of flow ducts.

Work with validated solutions

Our services are based on world-wide experience in industrial fluid mechanics, access to state-of-the-art software and hardware facilities, sophisticated flow-measuring equipment and modern laboratory facilities. The combination of all these, has allowed us to do proper validation of our numerical models against experimental testing and full-scale data measured on site.

Quick start

Upon order confirmation, receival of either 2D drawings or 3D geometries of anything from a unit to a full system, and receival of operating conditions, our team of experienced engineers and technicians are ready to start working on the flow optimisation.Personalised assistance

When choosing to work with us, you can expect a team of responsible engineers open to ongoing dialogue and discussion. We aim to meet your requests as best as possible. We will adapt our models to the specific conditions that your systems are subject to, addressing particular issues or topics of interest.Smart reporting

Our solutions are displayed in informative reports with a combination of flow contour plots, streamlines, and a compilation of all relevant values.

Work with us to ensure your flue gas cleaning systems operate efficiently. Contact our experts or watch our webinar for more insights.

Watch our webinar

Services

Combustion simulation and consultancy using CFD

Consultancy on design and optimisation for flow solutions ensuring optimum performance of the plant.

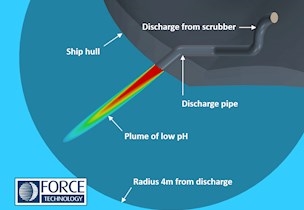

pH simulation of marine scrubber discharge

A quick and flexible model to document compliance with the marine scrubber discharge regulations.

Design and validation of processing systems using CFD

Improve the quality of your product or process by doing simulation studies in the design phase.

General design and flow consultancy

Design and optimisation of flow solutions for performance, energy efficiency and environmental impact.