Design and validation of efficient food and pharma processing systems using CFD

Improve the quality of your product or process using Computational Fluid Dynamics (CFD) simulations in the design phase. Simulation tools can also make sure you comply with regulations and standards in your industry.

Hygiene and safety regulations

The food and pharmaceutical industries are highly regulated. Hygiene and safety play a key role in the manufacturing of pharmaceutical products and food processing. Companies in these sectors need to meet very special requirements to comply with national and international standards. To meet these requirements, products and processes must reach the highest quality level.

Design high quality and efficient systems

In order to achieve high quality and efficient processing systems, detailed knowledge on the system’s behavior is required. CFD simulations provide insights into potential problem areas, making it possible to eradicate those areas before a real-life physical process has been set up.

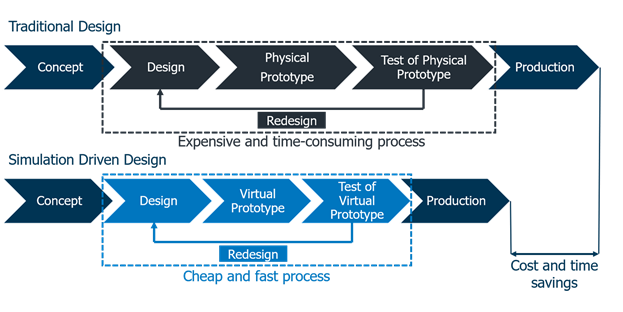

Virtual prototype in your design phase

As opposed to manufacture and testing of prototypes, CFD simulations:

- Provide detailed information that is not limited to a few measurement points in specific locations.

- Offer the opportunity to simulate scenarios that are dangerous or too expensive to carry out in real-life testing.

- Allow testing a large number of different setups, in a quick and affordable manner.

CFD enables the creation of a virtual prototype, which provides a high degree of understanding that can either precede or entirely replace the need for a physical prototype. This ensures a much more straightforward design process, reducing the expenses and long timeframes related to prototype manufacture and testing.

Experience in diverse types of systems

We have a very broad profile of expertise that can be allocated for specific needs. At FORCE Technology, we are often challenged to solve specific problems related to different applications, requiring not only knowledge about fluid mechanics but also about the different types of systems. Within the food and pharma industries, these are some of the applications where our CFD services can be of great advantage:

- Hygienic design

- Mixing tanks

- Cleaning, disinfection and sterilization

- Heat exchanger design

- Drying

- Refrigeration

- Baking

- Pasteurization

Below are some examples.

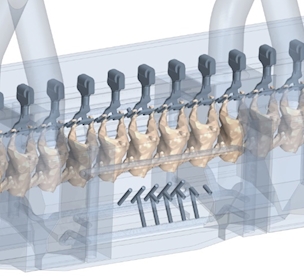

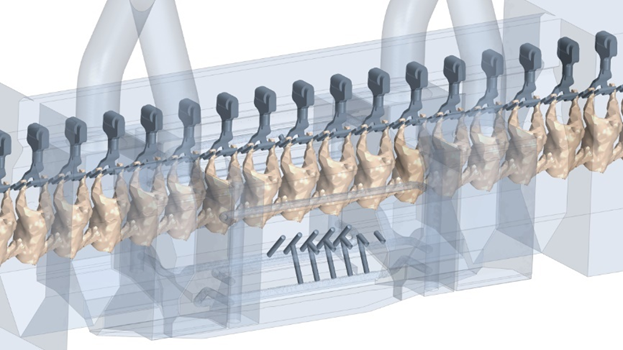

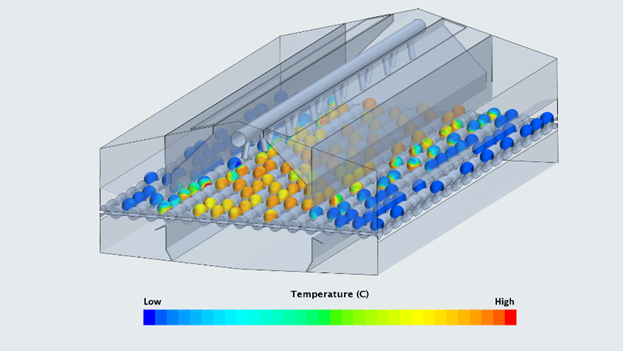

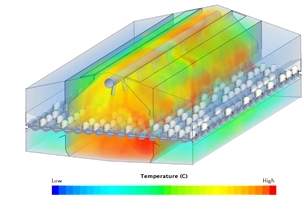

A CFD simulation of the disinfection process of eggs

You can read about our case study with Sonosteam’s disinfection system here.

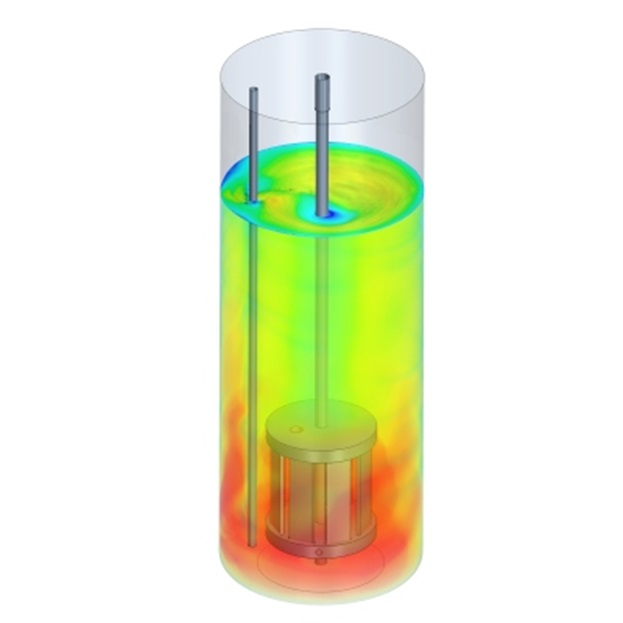

A CFD simulation of the performance of a mixing tank

Your system is our priority

It is our top priority to fully understand your system, and the improvements that you wish to achieve. This is why ongoing communication regarding background, and desired scope of work, is part of the experience of working with us.

We will adapt our CFD model to your preferences, in terms of level of detail and desired output, and you can expect support on the current status of your processing system, as well as on how to improve it.

At FORCE Technology, we develop CFD simulations in which all relevant aspects of your system are taken into account, including both the design and operation stage. You can see our CFD models as a method to test multiple design ideas, under different operating conditions, and gain early knowledge on how the combination of these have an effect on the system.

Contact us

Ready to optimize your processing system? Contact our CFD experts today for a tailored solution that improves efficiency and compliance.

Services

Food contact materials, compliance and own control

Manage regulations and documentation requirements in DK, EU or third countries.

Food safety and microbiology

Consultancy on microbiological food safety, hygienic design, cleaning and cleaning validation.

Corrosion and materials examinations

Corrosion and material data helps you in relation to design, product knowledge, and product failure.

Case