Flow laboratory for test and optimisation of industrial equipment

In the flow laboratory we perform test and optimisation of industrial and processing equipment through experimental tests on scale models.

A part of the flow laboratory is specialized in the optimization of SCR units (selective catalytic reduction) on the basis of experimental scale models.

We have many years of experience in testing flow parameters and working with energy and process efficiency through optimisation of gas flow in industrial equipment.

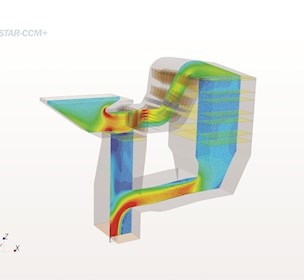

Based on the work in the laboratory and our decade long experience with mathematical modelling of fluid flow using Computational Fluid Dynamics (CFD) tools, we offer consultancy on the design and optimisation of flow solutions in a vast range of industries, helping our clients to optimise the energy efficiency of their equipment.

We have over the years helped optimising flow in equipment ranging from small valves to 100 m high tower furnaces.

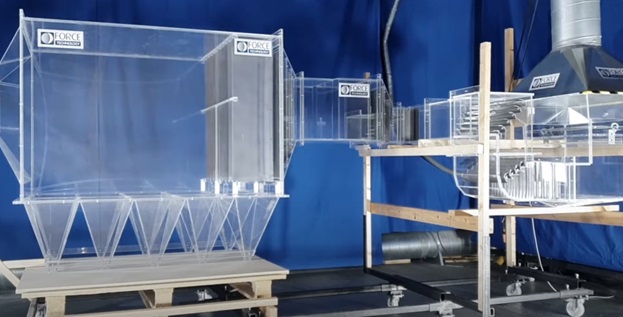

Specifically for SCR testing we have the capacity to carry out simultaneous investigations of several scale model units at any time. Geometric scaling of the units is typically between 1:15 and 1:10, which is equal to the models being between 3 and 6 meters high. The models are constructed entirely in acrylic glass to allow full optical access to the internal flow.

We can thereby disclose the entire internal process in the unit and thereby identify any problems regarding fluid flow and dust load. The models include scale ammonia injection grid, scale mixer and internals such as truss work and dust screens as laid out in cooperation with the client.

The model set-up allows for analysis of:

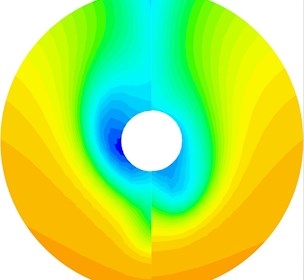

- Flow distribution at AIG and catalyst inlet

- Temperature stratification in the unit

- Chemical mixing at the catalyst

- Dust load on the catalyst layers

- Dust precipitation in ductwork

- APH inlet flow conditions

- Pressure distribution and loss

- Flue Gas Desulpherisation (FGD) unit efficiency.