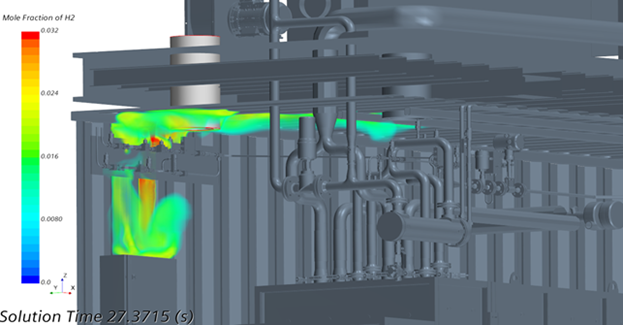

CFD simulations of green fuel leakage and dispersion

CFD enables risk assessment of hydrogen, ammonia, methanol or other green fuels. Optimise ATEX zones, ventilation and sensors for safe operation.

Simulation of risk and safety for green fuels

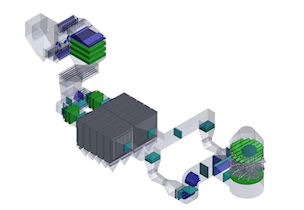

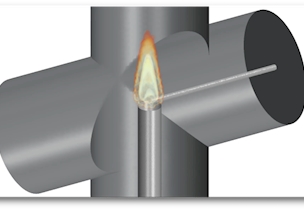

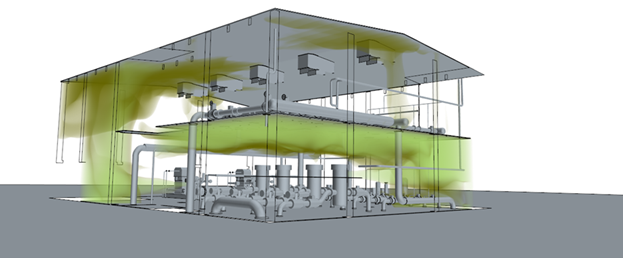

Green fuels such as hydrogen, ammonia or methanol can introduce major safety risks when leaks or spills occur, and the dispersion behaviour can be difficult to predict. Computational Fluid Dynamics (CFD) makes it possible to simulate leakage and dispersion of toxic gases in a virtual, risk-free environment. These simulations provide insight into how gases and liquids spread, supporting preventive design measures and strengthening compliance with ATEX and standards. The models use advanced 3D analyses that include wind, turbulence, evaporation, temperature and ventilation effects, tailored to specific project needs.

CFD supports safety compliance in green fuel operations

This service supports safety managers, engineers and compliance officers in production plants, storage facilities, harbours and transport systems working with hydrogen, ammonia, methanol or other green fuels. These operations face strict safety requirements, but the outcome of certain leakage scenarios can be difficult to predict, leading to problems with risk assessment.

CFD simulations enable:

- Identification of flammability and health risks, including exposure compared with AEGLs

- Can be used as documentation in ATEX and IEC hazardous zone classifications

- Designing effective ventilation and gas detection strategies

- Providing reliable evaluation of HAZID and HAZOP-detected scenarios

CFD simulations assist in smarter decision-making, leading to reduced costs

Ensure proper ATEX equipment and strengthen planning

- Avoid over-engineering and lower compliance costs by gaining reliable insight early in the design and safety planning process. Reduce equipment costs by avoiding oversimplified large ATEX zones, leading to unnecessary compliance requirements.

Support compliance with ATEX and IEC

- Generate accurate data for zone classification and safety documentation, including input for HAZID, HAZOP and regulatory submissions.

Optimise ventilation and detection systems

- Proper design by CFD leads to better ventilation, leading to reduced ATEX zone sizes. In addition, CFD consultancy can help detect or remove redundant sensors and increase detection reliability by optimising sensor positioning.

Maximise risk control within project constraints

- Avoid project delays, over-engineered solutions or a lack of proper precautions during risk management. CFD enables proper insights, giving the decision maker a solid foundation for making informed decisions when facilitating Power-to-X safety.

CFD simulations support ATEX, IEC and recognised safety assessment standards

- ATEX Directive 2014/34/EU – equipment and protective systems for explosive atmospheres

- IEC 60079-10-1 – classification of hazardous areas and explosive gas atmospheres

- HAZID (Hazard Identification) and HAZOP (Hazard and Operability) process support

- Documentation for safety cases and regulatory compliance