Ammonia combustion simulations pave the way to new green fuels

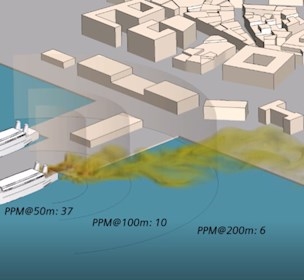

Research indicates that using CFD technology in fuel combustion tests allows companies to reduce or even replace expensive and time-consuming traditional physical methods. Data verification awaits.

Transitioning to a society that runs on green fuel requires a lot of research. For a potential fuel like ammonia to be a guaranteed safe, efficient and environmentally friendly energy source, it must be backed by vast quantities of verified data.

Computational Fluid Dynamics (CFD) is an alternative to expensive physical experiments

Traditional fuel combustion experiments consume fuel and require a substantial investment of time to record results, analyse them and improve operations. They also require a research team to manually measure and record data to find optimal combustion parameters.

Simulating an experiment on the computer makes it easier to see the result of combustion under various external factors or input parameters.

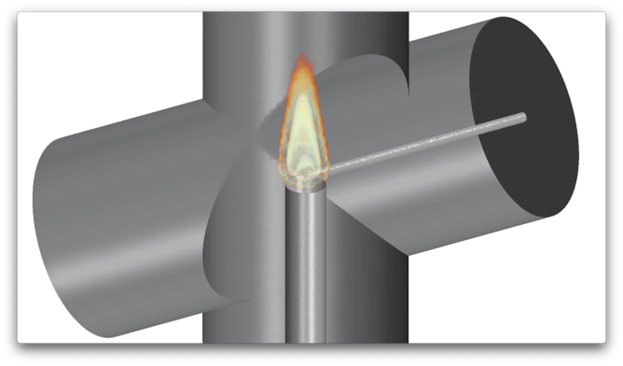

"By making a CFD model on the computer to simulate the physical ammonia combustion experiment, we can monitor the temperature distribution, visualise the flow in the burner and track the NOx emission under different ammonia-air ratios and flow rates. We believe that CFD simulation can support physical experiments during feasibility tests of new fuels such as ammonia. By simply changing the parameters on the computer, we can simulate the condition in a combustion burner and arrive at the optimal ammonia-air ratio and flow rate for combustion in a certain burner. Compared with traditional experiments, there is no doubt that CFD design can save time and reduce financial costs," FORCE Technology Emissions & Thermal Technologies Project Engineer Xin Li says.

Next up: validating the CFD ammonia combustion model

"We recently collaborated with an industry partner to get experimental data on the CFD process and consequences of burning ammonia. We have used the data to develop numerical simulation models that we believe in, but they require real-life validation. That's what we're working on now. When validated, we see that simulating fuel combustion using CFD can be relevant for companies working in transportational energy supply, manufacturing internal fuel combustion engines or industrial burner development.

We are currently looking for partners we can work with to co-develop and perform experiments based on our numerical CFD models. Get in touch with Xin Li to learn more.

The goal of our "Green fuels of the future" project is to, by the end of 2024, be able to assist the energy industry with impartial documentation on the reduction of emissions from a wide range of the future's new green fuels and technologies. The Danish Agency for Higher Education and Science has supported the project with contract funds.