Vortex Induced Vibrations or Motions (VIV/VIM)

Vortex Induced Vibrations or Motions (VIV/VIM) are important issues for the oil and gas industry. Model tests play a significant role in the evaluation of VIV/VIM.

Vortex shedding occurs on all blunt bodies subject to current. The vortex shedding results in alternating cross-flow forces on the body. If the natural frequencies of the body motions and of the vortex shedding approach each other, lock-on may occur, meaning that the vortex shedding synchronizes with the transverse oscillations of the body, resulting in large amplitudes.

We have extensive experience in VIV/VIM model tests of all kinds of structures prone to VIV/VIM, and we continue to improve and develop new test methods and equipment.

Examples of structures relevant for the oil and gas industry include stay cables, drilling and production risers, spanning pipelines, tensioned tethers and floating platforms such as SPAR platforms, semisubmersibles, TLPs, floating buoys under towage etc.

VIV of production platforms causes stress to risers, mooring lines and other equipment, and may have a significant effect on the fatigue life.

Model testing in the towing tank

Model tests are performed in the towing tank by towing the model to simulate the current. Tests can be made both in calm water and in waves. The model is held in place by a horizontal mooring system replicating the horizontal stiffness of the full scale system.

The motions of the model are measured in all 6 DOF by our optical tracking system, and the horizontal mooring force in the x and y directions are measured at the attachment points.

In addition, we can perform other types of measurements, for instance accelerations or structural loads.

VIV/VIM response of floating platforms is highly dependent on current direction relative to the platform. Model tests will therefore include a full range of approach angles as well as speeds. The carriage runs accurately both ahead and astern, so tests are often made either way to improve cost efficiency.

The presence of waves has in several cases proved to reduce the VIM cross flow amplitudes. Additional tests in waves can be performed to evaluate the effect of the waves.

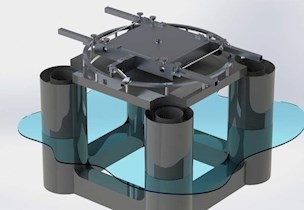

TLP tests using air-bearing push down system

Tension leg platforms (TLPs) can be tested using our air-bearing push down system which can replicate the tendon down forces without introducing frictional damping in the horizontal plane. This enables us to load the platform with correct mass and draught. The TLP is held in place by a horizontal mooring system as the one used for standard VIV/VIM tests.

Controlled damping

A damping device has been developed in order to introduce linear damping in the cross-flow direction. It is then possible to simulate additional damping from the risers and mooring lines/chains not physically modeled.