Giant robots could revolutionise Danish shipbuilding

In the research project LSP Ship Factory, researchers from The University of Southern Denmark together with FORCE Technology and 14 other partners aim to automate ship production with robots, AI and 3D printing. The project is supported by Innovation Fund Denmark and has a total budget of 47 million DKK.

Danish shipbuilding will be moving up into a new league. That is the goal of the research and development project LSP Ship Factory, which over the next 4.5 years will develop new automation solutions, and with the help of giant robots, AI and 3D printing, will be able to produce everything from ferries to frigates.

Researchers from The University of Southern Denmark, Danish Maritime, FORCE Technology and a range of shipyards, private companies and organizations are behind the project, and the partners expect to be able to increase productivity in shipbuilding by up to 60-80 percent.

In addition to increased productivity, the project also aims to strengthen security of supply and competitiveness, maintain Danish shipbuilding skills and counter the future labor shortage.

Providing 3D printing and welding skills

As project partner FORCE Technology makes its welding skills and 3D printing facility on Lindø available. The plan is for the most complicated parts of the physical setup to be 3D printed to ensure high quality and save time and resources.

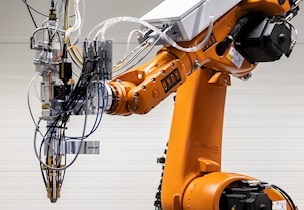

The project will take place at The University of Southern Denmarks Center for Large Structure Production (LSP). The physical framework of the center is currently under construction at the Port of Odense, including the unique 10-meter-tall gantry crane equipped with four robotic arms that can operate welding equipment, paint sprayers and grinding discs.

The idea is that the robots should be able to start producing ship modules and elements without programming and directly from a 3D drawing of the ship. It has the potential to revolutionise the entire maritime sector, and it might also draw some of the outsourced production back to Denmark.

(Image courtesy of Güdel)

(Image courtesy of Inrotech A/S)

Facts about LSP Ship Factory

- LSP is a research and innovation project supported by Innovation Fund Denmark. It runs for 4.5 years.

- There are a total of 15 partners involved in the project: SDU Center for Large Structure Production (LSP), Danske Maritime, Inrotech A/S, FORCE Technology, Simfact ApS, Fayard A/S, Orskov Yard A/S, Karstensens Shipyard A/S, Søby Shipyard A/S, Tuco Marine Group A/S, SDU Mechanical Engineering, Odense Maritime Technology A/S, Hauschildt Marine A/S, SH Group A/S and Odense Robotics.

- The project has received DKK 33 million in support from Innovation Fund Denmark and has a total budget of DKK 47 million.