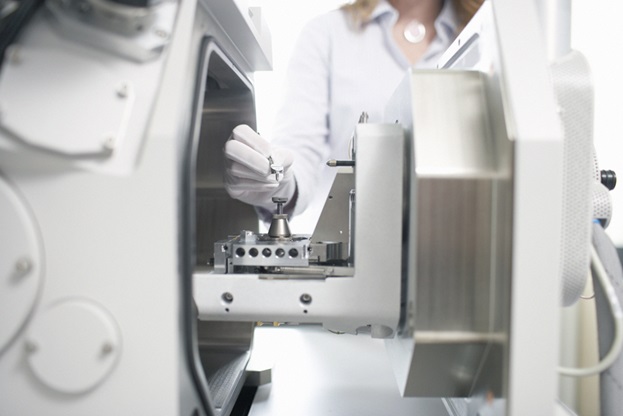

Surface characterisation laboratory

We have state-of-the-art equipment for surface characterisation and surface analysis. Our equipment covers both 3D-microscopy, electron microscopy and X-ray analysis.

With our advanced surface characterisation equipment, we are able to perform highly specialised analysis on many different and complex surfaces. Our experts can also advise on surface characterization and analysis of surfaces in connection with e.g. new processes, carry out troubleshooting and perform damage assessment.

Scanning Electron Microscopy (SEM) using Energy-Dispersive X-Ray Spectroscopy

We have two types of SEM in which surface characterisation can be done with nanometer range resolution.

SEM with internal ion source (Focused Ion Beam – FIB)

One of our SEM’s has an internal ion source (Focused Ion Beam – FIB). This allows analysis on and under the surface (in situ cross sectioning) and is very suitable for studying sub-surface structures. Expressed in popular terms it is a “Nano Swiss knife” as it is both possible to build and remove material with nanometer precision.

With the SEM we can also perform the following micro analyses:

- EDS (Energy Dispersive Spectroscopy)

- µ-XRF (Micro x-ray fluorescence)

- WDS (Wavelength Dispersive Spectroscopy)

- EBSD (Electron BackScattered Diffraction)

ESEM (Environmental scanning electron microscope)

We also have an ESEM (Environmental scanning electron microscope) which allows us to characterise humid or water containing test material. Examples of this are analysis of biological material without drying up the material.

Advanced optical 3D profilometry with AFM (Atomic Force Microscopy)

The equipment measures and visualises in 3D surface topographies of almost all solid materials in sizes from nm to cm. It is very convenient in order to support companies in development- and design processes of new materials and in relation to quality assurance of these.

The equipment also perform highly sophisticated surface-finish characterisation down to nano-level on both plane and highly curved surfaces.

X-ray Diffraction (XRD)

Equipment for determination of the crystal structure of crystalline materials.

Chemical analysis

We also have access to all the “conventional” chemical analyses, so we can carry out further analysis in connection with advanced characterisation of various material.

Characterisation of a wide spectrum of materials

With this equipment it is possible to both visualise and analyse in great detail (microanalysis down to 1 µm³). For that reason, we are able to characterise a wide spectrum of materials in relation to evaluating new processes, troubleshooting, damage assessment and many other purposes where microanalysis and visualisation are essential.

Services

Advanced surface characterisation and analysis

Investigation and analysis of surfaces, structures, fractured surfaces, particles, impurities etc.

Identification of foreign bodies and contaminants

Foreign material can be a potential hazard in pharma and food production

Test and analysis of plastics and composites

Ensure optimal material selection and design when working with polymers and composites.