Mechanical tests of large structures

Full-size structures can be exposed to static and dynamic multi-axial loads or fatigue testing and applied with simulated loading from e.g. waves or wind.

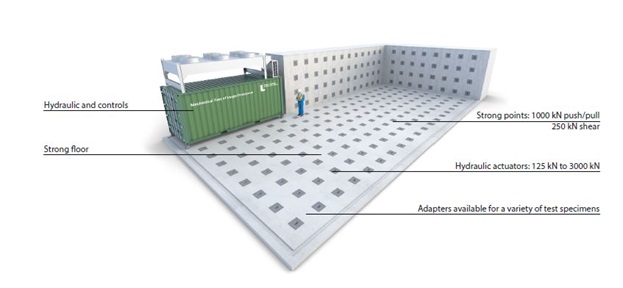

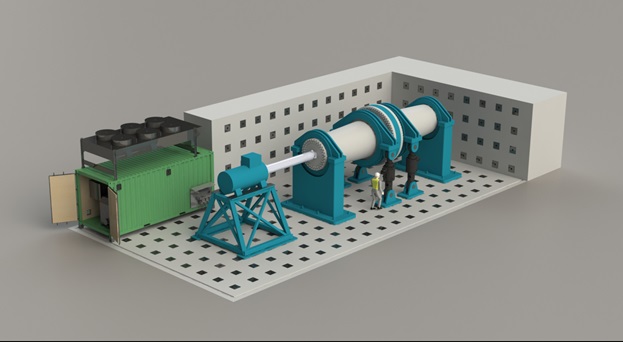

High capacity mechanical test bench

Testing of large components and structures can be performed on the mechanical test bench at Lindø Component and Structure Testing A/S. The size and capacity of the test bench enables testing with realistic forces.

Full-scale testing can supplement the testing of sub-systems and components, where complex mechanical or structural systems can be tested in near operational conditions.

The ability to test large components or full-scale systems will give you the necessary verification to ensure your system meets the high demands of its operating environment and you get competent guidance on mechanical testing of large components.

Mechanical test bench:

- Size (floor): 20 x 9 m

- Size walls: 13 x 4 m and 9 x 4 m (WxH)

- Cylinder capacity: 125 kN up to 3 MN

- No. of cylinders: Up to 6 simutaneously

- Max. bending mom: 60 MNm.

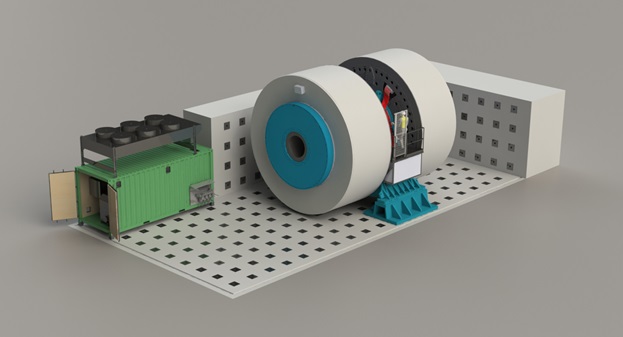

• Performance and functional testing

• Full torque load testing

• Robustness testing

• Determination of generator efficiency

• Short-circuit testing

• Heat-run testing

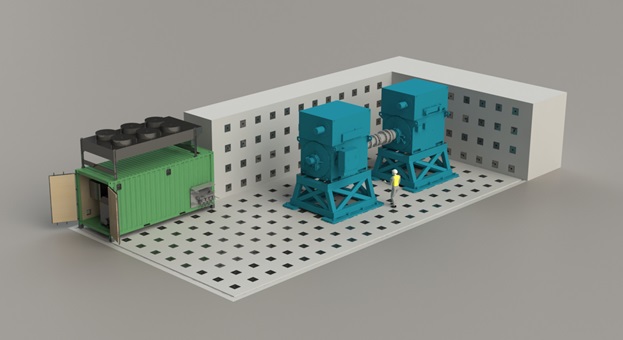

• Performance and functional testing

• Full torque load testing

• Robustness testing

• Determination of generator efficiency

• Short-circuit testing

• Heat-run testing

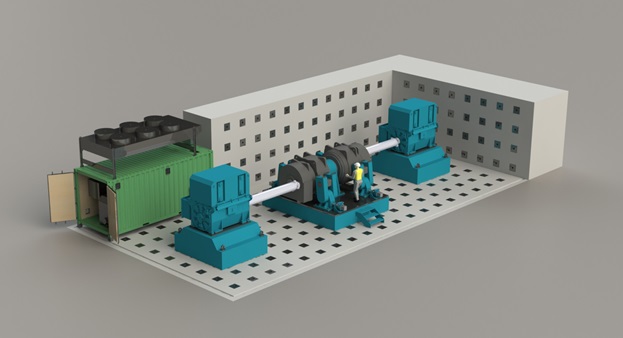

• Performance and functional testing

• Full torque load testing

• Robustness testing

• Determination of generator efficiency

• Short-circuit testing

• Heat-run testing

• Performance and functional testing

• Endurance test of internal mechanical components (gears, bearings, etc.)

• Lubrication performance testing

• Determination of gearbox efficiency