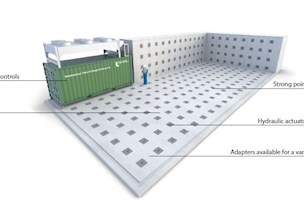

Climatic test chamber for tests of large components

In the climatic test chamber, large components, structures and functional systems can be tested under realistic atmospheric sea conditions.

A climatic chamber for testing of both offshore and land based systems

The climatic test chamber is the largest commercially available in Northern Europe (900 m3) providing a combination of three different environmental systems to perfectly simulate an offshore environment:

- Temperature control

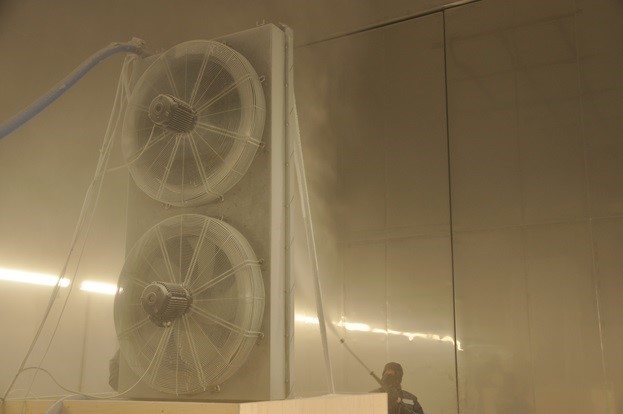

- Humidity control

- Salt spray.

The three environmental parameters can be individually controlled or be programmed as combined effects to simulate the harsh offshore atmosphere as realistically as possible.

Thorough testing creates robust products

Thorough testing, evaluation and optimization of your equipment before installation will help ensure the lifetime robustness of your product, and our specialists are available to give guidance on the best test program for climatic testing of large components. In the climate chamber, we can test according to a large number of standards as needed.

Our corrosion and metallurgy experts will be available to help during the entire design and production chain. This will enable you to find the right solution for your product and avoid unexpected corrosion, material damage, or operational failures.

Customised tests

Testing in the climatic chamber can be customised to meet your specific demands. If you need assistance in the process of designing the test for your needs, we shall be happy to guide you. The climatic chamber is also capable of performing according to a number of standards.

Climatic chamber:

- Test chamber: 14 x 8 x 8 m

- Temperature range from -60 °C to +60 °C

- Humidity range: 10 %RH to 100 %RH

- Salt spray: Adjustable from 3 sides

- Cooling capacity: 210 kW @ -10 °C and 60 kW @ -35°C

• Testing of product at low temperature (-20 °C)

• Over icing test using water spray

• Data acquisition

• Arctic climate simulation

• Battery lifetime testing

• Performance testing

• Functional testing

• Corrosion testing

• Realistic operational condition simulation (-35°C to +60°C, humidity control, salt spray)• Functional testing

• Product validation

• Performance testing

• Heavy, large scale product testing (maximum floor load of over 1000 tons)

• Thermal stress test in operational conditions (from -20 to approximately +50 °C)

• System validation

• Over icing test using water spray

• Component function and integrity testing

• Test duration – 400 cycles, 7 days