Emissions from pyrolysis plants – overview of environmental impact and legal requirements

What are the legal requirements for emissions from pyrolysis plants – and which substances require particular attention when the flue gas reaches the surrounding environment?

Pyrolysis plants and emissions

Denmark aims to become climate neutral by 2045 and to reduce greenhouse gas emissions by 110 percent by 2050 compared with 1990 levels. This means that Denmark must not only be neutral and eliminate all its emissions, but also remove more from the atmosphere than it emits, for example CO₂.

Pyrolysis has significant potential for CO₂ storage and for the recycling or utilisation of organic waste streams [2], [6], and the Danish government has identified pyrolysis as a possible pathway to achieving the climate targets [1]. The government has therefore allocated financial resources and initiated projects to promote the deployment and technological development of pyrolysis, and to investigate the environmental impact, regulatory needs and climate effects of the process [1].

Interest in pyrolysis is increasing, both in Denmark and abroad [2], [3], [4], but the method is far from new. For example, pyrolysis oils were used throughout history in Egypt for embalming the dead [3], and in the Amazon, pre-Columbian societies used pyrolysis to produce charcoal for soil improvement several thousand years ago [5].

This article provides an overview of emissions from pyrolysis plants and the applicable legislation that regulates the environmental impact of emissions to the surrounding environment.

The pyrolysis process explained briefly

Pyrolysis is a thermal treatment process that takes place at high temperatures, typically above 300-400 °C, under oxygen-free conditions. The absence of oxygen allows the formation of synthesis gas/pyrolysis gas, pyrolysis oils and solid carbon (biochar). In addition, the heat generated in the process can potentially be utilised.

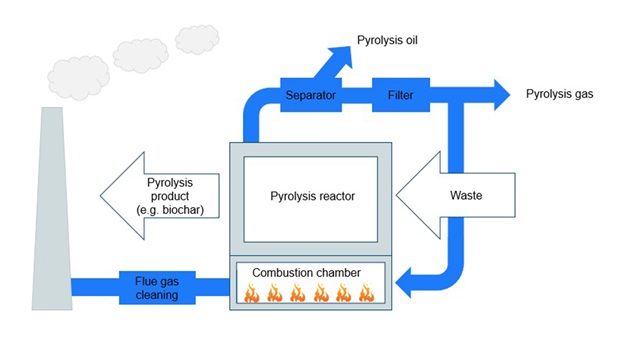

Figure 1 below shows a simplified example of a pyrolysis plant.

The material used in the pyrolysis process typically consists of different types of waste and residual products. What these materials have in common is that after pyrolysis they can be used in a more appropriate way – for example as a raw material, a complex material with specific chemical properties or an energy resource. In the following, these materials are collectively referred to as “waste”, regardless of their original nature.

Waste type, temperature profile and residence time play a decisive role in which pyrolysis products are formed – and in what quantities. By controlling the heating rate, final temperature and gas residence time, and possibly the addition of air or steam, it is possible to optimise the production of biochar, pyrolysis oil and gas [3], [6]. Slow heating, low final temperature and long gas residence time maximise the production of biochar. Rapid heating, moderate final temperature and short gas residence time instead maximise oil production, while slow heating, high final temperature and long gas residence time maximise gas production.

The pyrolysis process can take place either endothermically or exothermically, depending on the material and the process conditions. An endothermic reaction requires external heat input to maintain the pyrolysis process, whereas an exothermic reaction can contribute to energy production, as certain materials release heat during decomposition. For endothermic pyrolysis processes, the pyrolysis gas produced is often used to generate heat for the process itself. This combustion leads to emissions to the ambient air. The national legislation that applies to these emissions is addressed in this article.

Waste types used for pyrolysis in Denmark

In Denmark, commercial pyrolysis production takes place at plants of varying size, from 0.2-20 MW [1]. In 2024, around 6 commercial plants were in operation nationwide, with several more planned [1]. A common feature of the existing pyrolysis plants is that the heat is not utilised in the energy supply.

Emissions from the combustion of pyrolysis gas are highly dependent on the chemical composition of the feedstock and thus on which materials are subjected to pyrolysis [3], [6].

The waste and residual products that are particularly suitable for use in Denmark include: sewage sludge, plastic waste, end-of-life tyres, residual biomass from biogas plants, agriculture and the food industry, garden and park waste, seaweed and sediments [2], [6]. Certain waste types require size reduction and pelletising before pyrolysis, and some types contain so much water that pre-drying is necessary [6].

Emissions from combustion of pyrolysis gas

Regardless of the composition of the waste material, pyrolysis gas always contains CO₂, CO, H₂O, H₂ and CH₄. In addition, it contains several lighter hydrocarbons and tar compounds in varying amounts. Other compounds may also be released or formed (see Table 1), depending on the waste type, impurities in the waste, the type of plant and the pyrolysis process, including temperature and residence time [3]. The components released or formed during the pyrolysis process may create challenges for the plant in the form of corrosion of materials and deposits/blockages. Moreover, environmentally harmful emissions can be formed during the combustion of the pyrolysis gas [6].

The flue gas from combustion of the pyrolysis gas has the potential to contain fewer problematic substances than flue gas from the combustion of solid material. Likewise, condensation of oil and heavy volatile compounds, as well as gas cleaning prior to combustion, can further reduce the amount of undesirable substances in the gas and protect the plant.

Flue gas from combustion of pyrolysis gas contains particles that primarily consist of unburned carbon and possibly metals. If oil mists are not removed effectively, combustion will lead to increased soot formation. During combustion of the pyrolysis gas, a large proportion of the CO is converted to CO₂. However, CO can also be formed in the combustion process, which may contribute to the total CO emissions [6].

Examples of emissions from different waste types

Table 1 shows examples of emissions that may be released during combustion of pyrolysis gas, based on selected waste types. The overview includes both theoretically expected emissions [6] and measured components that have been reported in the scientific literature [3]. The overview is not exhaustive. The measured emissions vary in quantity and may occur at concentrations both below and above the applicable emission limit values, depending on process conditions and waste composition [3].

| Waste type | Typical pyrolysis products | Selected expected emissions associated with the waste material (theoretically released) [6] | Reported measured emissions in the literature |

| Tyres (non-biobased) | Primarily Carbon Black secondary pyrolysis oil |

H₂S and other sulphur compounds in the pyrolysis gas are converted, for example, to SO₂. HCl and HF are expected in lower concentrations. Tar compounds, including PAHs, if combustion is not optimal. NOx in lower concentrations. CO from the pyrolysis gas and from the combustion process. |

PAHs [7], [8], [9] TOC, SO2 [10] PM, CO, NOx, HCl, HF [7], [10] PCDD/Fs [7], [9], [11] PCPh, ClBz, PBPh, PBDD/Fs [9] |

| Plastics (non-biobased) |

Pyrolysis oil | PAHs are expected to condense with the pyrolysis oil. Components in plastic waste, such as melamine containing nitrogen, can lead to emissions of, for example, NH₃ and HCN. PVC and salt from food residues can result in chlorinated compounds, such as HCl. |

PCBs, PCDD/Fs [12] |

| Sewage sludge (non-vegetable) | Biochar | Heavy metals, for example Cd and As. PM, NOx, SO₂, HCl, possibly dioxins and furans. |

Chlorinated VOCs, 1,3,5-trimethylbenzene and xylene [14]. PM and metals (As, Cd and Pb) [15]. |

| Biomass (for example garden/park waste and agricultural residues, biobased and vegetable) | Biochar | - | CO, C4H8, C3H6O, C2H4O2, C4H10, C2H4O2, NH3 [16] H2S, NO, NO2, SO2 [17] PM [17], [18], [19], [20], [21], [22], [23] CH4, NMVOC, CO2, SO2, HCl [19] CO, NOx, SO2[22] ΣPAH-16, CO, NO2, NMVOC, CO2, PM10 [24] CO2, CO, NMVOC, CH4, PM, NOx [25] PAHs [26] |

| Polyurethane foam (PUF) (non-biobased) | Pyrolysis oil | - | ClBzs, PCDD/Fs [27] NH3, HCN, NO, NO2 [28] |

| Household waste (partly biobased) | Biochar and pyrolysis gas | - | NOx, CO, PM, HCl, HF, PCDD/Fs, PAHs [7] SO2, NO, NO2, NH3, HCN [30] |

Table 1: Theoretical and published measured examples of emissions from pyrolysis, by waste type

Regulation of emissions from pyrolysis plants

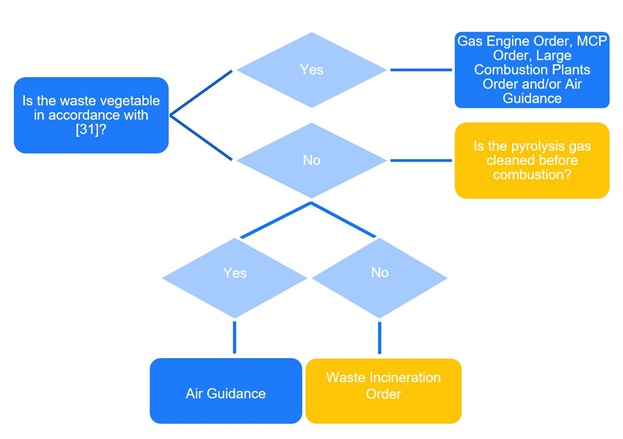

The regulation of emissions from combustion of the pyrolysis gas depends, among other things, on the type of waste and the type of plant, as well as on whether the gas is cleaned before combustion.

The environmental permit for each individual pyrolysis plant determines the emission limit values that must be complied with. The emission limits may derive from either the Waste Incineration Order (Affaldsforbrændingsbekendtgørelsen) [31], the Air Guidance (Luftvejledningen) [32], the Large Combustion Plants Order (Store fyr-bekendtgørelsen) [33], the MCP Order (MCP-bekendtgørelsen) [34] or the Gas Engine Order (Gasmotorbekendtgørelsen) [35].

Figure 2 shows an overview of the legislation that regulates emissions from combustion of pyrolysis gas.

As shown in Figure 2, it is important for regulation whether the input material is vegetable biomass waste. In the Waste Incineration Order, vegetable biomass waste is defined as:

a) Vegetable waste from agriculture and forestry

b) Vegetable waste from the food industry, if the combustion heat is utilised

c) Fibrous vegetable waste from the production of virgin pulp and the production of paper from pulp, if it is co-incinerated at the production site and the combustion heat is utilised

d) Cork waste

e) Wood waste, except wood that may contain halogenated organic compounds or heavy metals as a result of treatment with wood preservatives or surface treatment, including in particular wood from construction and demolition waste.

Conditions in the Air Guidance

The Air Guidance (Luftvejledningen) sets out two conditions that pyrolysis plants may be subject to. Condition 1 requires that emissions do not exceed the values allowed for natural gas-fired combustion plants (see Table 2). This can, in some cases, be achieved by cleaning the gas before combustion.

| Nominal input thermal capacity (1) | Substances with emission limit values | Regulatory framework with emission limit values |

| < 120 kW | - | - |

| ≥ 120 kW and < 1 MW | NOx and CO |

Air Guidance Gas Engine Order |

| ≥ 1 MW and < 50 MW | NOx and CO | MCP order |

| ≥ 50 MW (2) | NOx, SO2, dust and CO | Large Combustion Plants Order and BAT conclusions for large combustion plants |

Table 2: Emission limit values applicable to natural gas-fired combustion plants

(1) The nominal input thermal capacity of the plant that combusts the gasification and pyrolysis gas.

(2) The total nominal input thermal capacity of the plant, cf. Section 3 of the Large Combustion Plants Order.

If the combustion of the cleaned gas results in emissions of other substances or in higher quantities than from natural gas-fired plants, condition 2 applies. In that case, the pyrolysis process must comply with the relevant emission limit values in the Waste Incineration Order, cf. section 7.6.2.1, even if the gasification and pyrolysis plant is not covered by the Order.

Knowledge of waste type and process forms the basis for the environmental permit. It is also the environmental permit that ultimately determines which components and associated limit values must be complied with.