Prevent water and moisture from accumulating in "watertight" devices with EquiLung

EquiLung, an "artificial lung", may be able to solve the common problem of humidity and water penetrating outdoor products. The solution is undergoing practical testing.

Temperature changes create pressure changes

When a "watertight" device (i.e., one with a high IP rating) is subjected to temperature changes, they produce corresponding pressure changes inside the device. At lower temperatures, the pressure inside the device will be less than that of the surroundings; at higher temperatures, the internal pressure will be greater.

Devices may be rapidly cooled due to such influences as rainy weather, pressure washing, and ordinary temperature changes throughout the day.

Pressure drops can promote moisture and water penetration

Cooling and a subsequent pressure drop can give rise to the following common problems:

- Penetration of liquid water through gaskets, cables, and ports. This normally results in large droplets or accumulations of water that slowly disappear when the device is opened.

- Penetration of humid air (containing gaseous water; i.e., water vapour) through gaskets, cables, and ports. This normally results in a fine layer of internal condensation that rapidly disappears when the device is opened.

In some cases, the pressure differential may be great enough to deform gaskets, pulling them in and further reducing water tightness.

Liquid water, or "just" high relative humidity inside a device typically leads to:

- Condensation

- Electrolytic migration

- Corrosion

- Increased leakage currents

- Actual short circuits

- Degradation of insulating materials, etc.

How can these penetration problems be mitigated?

Problem 1 described above can normally be mitigated by drilling a suitable hole in the bottom of the device (5-10 mm in diameter), or by using a membrane* popularly known as a "Gore-Tex® membrane". The latter is clearly the better solution if there is a risk of dust or water entering from multiple sides, as they could pass directly through the drilled hole.

However, neither of these solutions can prevent Problem 2 from occurring. Humid air will still be able to accumulate inside the device via diffusion through a hole or membrane. Ultimately, this means that the humidity inside the device will eventually be equal to—if not higherthan—the ambient humidity. If the device has a significant thermal mass inside, humidity accumulation may occur. This can present a risk of humidity condensing onto critical parts.

EquiLung: a possible solution

FORCE Technology is working on a solution designed to prevent the penetration of both liquid water and humid air when pressure changes occur. We call it EquiLung (from "equipment lung").

EquiLung is part of "Long Live Products and Materials", a project FORCE Technology is conducting for the Danish Agency for Higher Education and Science. At its core, the project aims to improve product sustainability based on longer, known lifetimes.

How EquiLung works

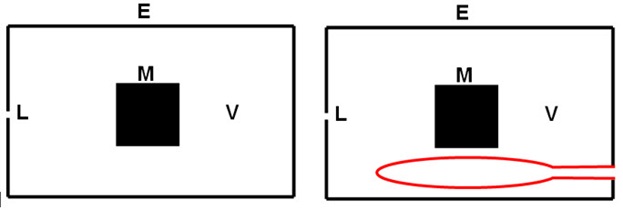

An EquiLung is essentially a balloon or bag (in red) placed in an opening on a device, as shown in Figure 2.

In the figure: E is the device enclosure, V is the free volume inside the unit, M is a thermal mass (e.g., transformer, large condenser, coil, etc.), and L is the equivalent leakage from suboptimal gaskets, ports, and cables (due to flow along the wires inside) expressed as the diameter of a hole. Typical values of L are 0.01–0.3 mm for "watertight" devices.

Pressure changes caused by temperature changes

Supposing that the temperature in Figure 2 has been stable at 25°C for some time, there is no pressure differential between the inside and outside of the device. This, in turn, means that there is no air flow through L, and the EquiLung remains as it is.

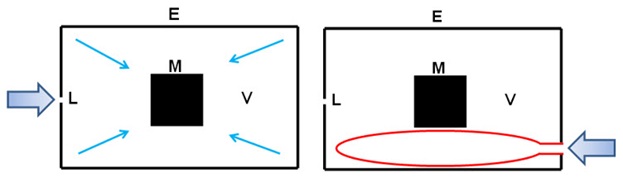

If the temperature in the device then falls to 10°C, as it might in rainy weather or when being pressure-cleaned, the air inside will become denser, producing a drop in pressure. The result of this is shown in Figure 3.

According to the ideal gas law (p * V = n * R * T), the pressure falls by about 5%, or 5500 Pa. This means that the device's walls, gaskets, and ports are subjected to an inward force of about 550 kg per m2, which is a significant load.

Without the EquiLung (left), this pressure differential causes air to flow into the device through L, as indicated by the blue arrow. During rainy weather and pressure-cleaning, the air is nearly saturated with water, and it may even contain small droplets that will be pulled into the device.

With the EquiLung (right), air is pulled into the sealed EquiLung, inflating it. The inflation equalises the pressure differential between the device and its environment. If the EquiLung is easily inflated and the diameter of its insertion point is much greater than L, the flow of air through L will theoretically be zero.

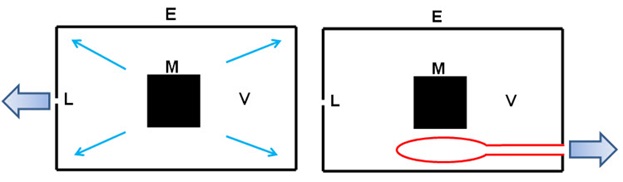

If the temperature inside the device then rises above 25°C, such as to 40°C, the opposite happens, as shown in Figure 4.

Here, the air in the device expands, causing the pressure to rise.

Without the EquiLung (left), this pressure differential causes air to flow out of the device through L, as indicated by the blue arrow.

With the EquiLung (right), the air is forced out of the sealed EquiLung, collapsing it. The pressure differential between the inside of the device and its environment is again equalised, and the air flow through L will theoretically be zero.

Under what conditions does the EquiLung work best?

Basic requirements for the EquiLung to function optimally are as follows:

- It must be easily inflated and collapsed (ideally without force).

- It must be airtight.

- It must inhibit diffusion (< 0.01 gH2O / m2 * day).

- It must be mechanically strong.

Examples of suitable candidates include:

- Metallised (> 5-10 µm) polymer "balloon" or bag (e.g., metallised PE/PET)

- Rubber "balloon" (e.g., made from butyl rubber)

Feasibility study of EquiLung

EquiLung works in theory and it has been tested in practice that EquiLung provides effective moisture and water protection for electronic devices.

Two test runs have been conducted:

- 10- to 30-day HACT (highly accelerated corrosion test), periodic spraying with fresh water

- 10- to 30-day cyclic humidity per IEC 60068-2-38, Test Z/AD (composite temperature/humidity cyclic test)

These two tests were selected for their ability to determine the effects of ingress and accumulation by a combination of either liquid water and water vapour or water vapour alone, at varying temperatures and high humidity. Several types of EquiLung have been tested in a standard electronics enclosure (made of aluminium) with an IP69 rating.

* The word "membrane" is also commonly used in reference to "breathable" fabrics used for clothing, potentially causing confusion. A "true" Gore-Tex® membrane is made of expanded PTFE (polytetrafluorethylene, or Teflon). This is essentially a material full of very small holes that allow air and water vapour to pass, but not liquid water.

Source: SPM report 176 ”Humidity testing of electronics and mechanics”.