Do you remember to service your cathodic protection system?

Even if you have a cathodic protection system on your concrete structure and the reinforcement should be protected it may not function optimally. It may be expensive with respect to unforeseen repairs

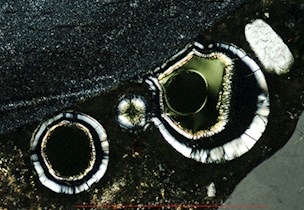

Reinforcement corrosion in a concrete structure may have serious consequences. Over time, the steel reinforcement will start to corrode, and this affects the stability and safety of the structure.

The reinforcement corrosion occurs when the passive layer, which exists naturally on the steel reinforcement, slowly disintegrates. A cathodic protection system may ensure that the corrosion is halted by applying a weak current to the steel reinforcement.

Cathodic protection systems are typically installed here:

- Bridges, especially with column bases partly submerges in sea water

- Swimming pools

- Tunnel and drain/discharge pipes

- Balcony access/cantilevers/suspension posts

- Balconies

- Multi-storey car parks

- Subsea structures such as harbour/quay structures, cooling water channels

- Industrial plants, especially concrete tanks

- Wind turbine foundations.

Avoid expensive repairs with service of your cathodic protection system

Now, you shouldn’t think that all is well just because you have installed a system for cathodic protection on the concrete structure. Annual service is at least just as important.

Unfortunately, we have seen a lot of examples that the system has not been maintained, so in many cases it does not function as intended but rather provides a false sense of security.

If it has not functioned for approx. four months there is an imminent risk that the steel reinforcement has begun to corrode again. This may result in major damage to the concrete structure which is very expensive to repair. If worse comes to worst, the structure may collapse.

Examples of reasons for absence of cathodic protection

There may be many reasons that a cathodic protection system is no longer functional. Below are some of the typical examples observed during inspection of the systems.

The timer is an important component in swimming pools

The reinforcement in a swimming pool is naturally exposed to aggressive salts such as chlorine from the pool water. It is therefore quite common to have a cathodic protection system to preserve the reinforcement in the structure.

If the system does not function optimally the facility inspector or the builder usually does not discover the problems until there is visual damage in the form of corrosion in the pool walls, or when the tiles begin to loosen or fall off. Now, repair becomes really expensive.

The reason for the absence of protection of the steel reinforcement may sometimes be found in the timer on the system. The system is set to be functional during the period where there are no guests in the pool, and movement sensors automatically disconnect the system when there are guests. However, in case of a power failure, the timer may be activated in the morning instead of at closing time but will then be turned off due to the movement sensors.

There may therefore be minimal protection or perhaps no protection at all around the clock. In rare cases, the timer may also be set incorrectly from the beginning.

Fire may destroy the cathodic protection in a larger area than expected

In case of a fire, for example along a balcony access in residential construction, all wires for the local cathodic protection system may have melted. The builder/contractor may not think of this during repair of the damage. The builder may thus erroneously think that the remaining part of the balcony access is still cathodically protected.A constant feed current is a requirement for optimal protection

In order for a cathodic protection system to be functional it must have a constant 220 V feed current. We have seen examples that a service passage in a public swimming pool facility has been filled up with a lot of discarded objects from the facility, which has unintentionally caused the cabling for the system to be destroyed. Part of the steel reinforcement is then no longer protected.

There are also examples that contractors have unknowingly cut the wire for the system because they believed that it was not in use. If it is not detected the corrosion may accelerate and result in expensive repair.

Changed conditions near the structure change the protection of the reinforcement

All cathodic protection systems are designed to suit exactly the structure it is intended to protect. It is therefore important to adjust the system in case of changes near the concrete. If, for example, it becomes drier around the structure because asphalt is laid where rainwater used to run directly into the ground, conductivity is reduced, and now the current cannot reach as far as it used to.

The opposite may also apply if the system is flooded and thus short-circuits, leaving the structure unprotected.

If there will be no salting in the winter in a multi-storey car part in the future and snow and slush are only removed mechanically a new situation arises where the system needs to be adjusted to provide maximum protection.

If the surfacing on the balcony access is worn, and a protective surface coating is applied this also changes the original conditions resulting in reduced protection of the steel reinforcement.

Service contract prevents expensive and unforeseen repairs

If you want to obtain maximum protection from your cathodic protection system, it is important that you have it serviced 1-2 times annually depending on the essential significance of the construction for the total structure. All systems are different and require different maintenance.

If you have spent a large amount of money having it installed the cost of maintenance is very low. On the contrary, the money paid for the system may have been wasted, and you end up with major and expensive repairs.

FORCE Technology services many cathodic protection systems annually, and we are able to service all types of systems no matter who has supplied it.

Our service contract includes:

- Control and assessment of the degree of protection

- Any adjustment of applied current

- Inspection of previous repairs

- Visual review of damage to adjoining concrete structures

- Troubleshooting of systems and replacement of defective components

- Recommendation for repair of damage.

In, for example, a public swimming pool facility, we examine whether the entire pool is properly protected. We also examine unprotected areas, which could be a promenade deck, both from above and from below to assess any damage. It may be necessary to increase the protection of the concrete structures.

Please contact us if you want to find out how we can help you service, troubleshoot or adjust your cathodic protection system.