Comply with standards for climatic and mechanical testing

Well-defined and reproducible tests in accordance with international standards are fundamental to successful testing that is recognised globally.

FORCE Technology is participating in standardisation in DS/S-604 – ‘environmental conditions, classification and methods for testing’ and therefore are at the forefront when it comes to developing standards in climatic and mechanical testing.

Information about storage, transport and use environments and the different influences they have is crucial in relation to specifying relevant tests. IEC Technical Committee 104 (TC 104) covers standardisation within environmental conditions and the classification of these, as described in IEC 60721, i.e. the description and quantification of environmental parameters such as temperature, humidity, vibration, shock and corrosive effects, classification of environmental parameters and related test requirements. It is a well of useful information, which companies and FORCE Technology can exploit when specifying environmental testing for a product.

Help in specifying and performing excellent tests

The individual test methods are described in IEC 60068 “Environmental testing”– Part 2-X. To put it simply, the standard series describes how you perform a good test of electrical, electro-mechanical or electronic equipment or devices, their subassemblies, modules and components. The numbers of the standards are organised so that X stands for the individual test. For example, IEC 60062-2-6 describes sinususoidal vibration and IEC 60068-2-30 cyclicic humdity. One of the most recent standard to be added has been designated with the number IEC 60068-2-85 and concerns vibration and “long time history replication”. At some point IEC decided to add 60000 to the number, so you can find old references to the standards that are named IEC 68-2-X.The standards describe a range of preferred severities, but it is up to the companies themselves or with help from FORCE Technology to define the severity of a given test. This contrary to popular belief that it is enough simply to refer to the standard. It is also necessary to indicate the severityof a test, e.g. temperature and duration or frequency range, amplitude, number of axes and duration.

There are also special standards found within the series IEC 60068-1 and IEC 60068-3, which guide the user and provide background information on e.g. test equipment.

Checklists in the standards

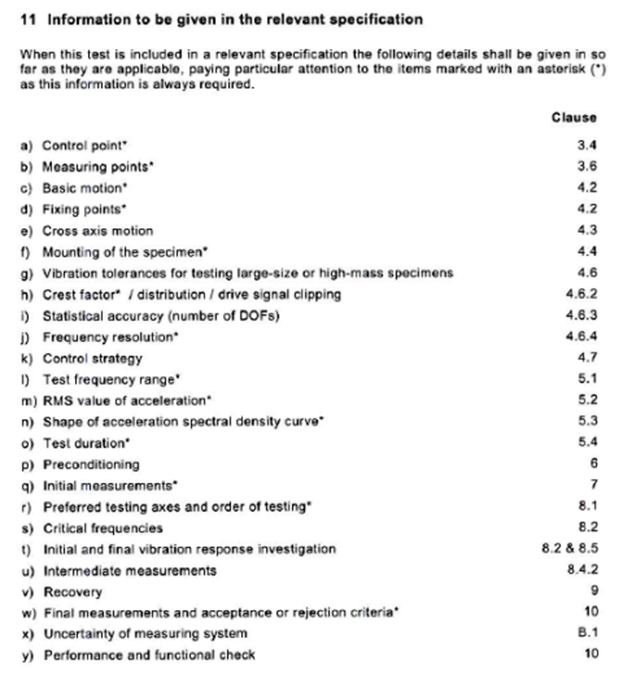

The standards help by having a checklist for each individual standard that shows the user what needs to be specified before the test can be initiated. As an example, the checklist for random vibration (IEC 60068-2-64, Test Fh) is extremely detailed and can be seen below:

Not a recipe book

Despite detailed checklists, the mechanical standards in particular describe the need for “engineering judgement”, because they are concerned with physical testing, where the test specimen may have significant influence on the exposure, i.e. this is not simply a recipe book that can be blindly followed.For climatic testing, requirements on determining preconditioning and recovery are especially important. The purpose of a steady state humidity test is not condensation, so preconditioning in the form of temperature stabilisation at the test temperature ensures that you avoid condensation when the humidity is added. Similarly, recovery at room temperature after a cold test before opening the climatic chamber also helps to avoid undesirable condensation, or in other circumstances to ensure that there are well-defined conditions for function testing or measurements to be performed under.

Important changes

As opposed to standards for EMC and radio technical tests, the current standards in climatic and mechanical testing do not differ fundamentally from the standards that were drawn up 10 years ago. This is because the standards deal with fundamentally physical things, that are not so dependent on technological development.The most significant changes relate to the test equipment. Previous standards for high and low temperature testing of heat-dissipating test specimens operated primarily with tests under free air conditions. In the more recent standards from 2008, the tester works instead with “low” and “high air speed”, where the dividing line is whether the air flow reduces the test object temperature by more or less than 5K. A check of this is critical to obtaining accurate results when testing heat-dissipating specimens.