Vibration tests are often performed to verify that a product meets specific requirements or to understand a product’s robustness to the conditions that it may meet during transport or use.

It can be quite a challenge to get optimal benefit from a vibration test, as the tester comes up against a great many technical questions regarding vibration that can be difficult to answer without years of experience in this field. Here are five useful tips that will help you get more out of your vibration test.

1. Prepare yourself well before commencing the test

There is a saying that “good planning is half the battle”, and this certainly applies to vibration testing. Having a clear specification with a description of all the necessary details is thus crucial to an efficient test procedure. Note that it is not enough to simply make reference to a standard, even if this might be an internationally recognised one. For example, it states clearly in IEC 60068-2-6 (a standard dealing with sine vibration) that there are a great many details besides frequency range, level, and time that must be determined in a relevant specification before it is time to perform the test. Whether a particular test shall be “operational” or “non-operational” along with a description of the specific acceptance criteria is something that needs to be determined for the specific task. Here are two examples of check lists for a vibration test:

ECR-205 and

IEC 60068-2-6.

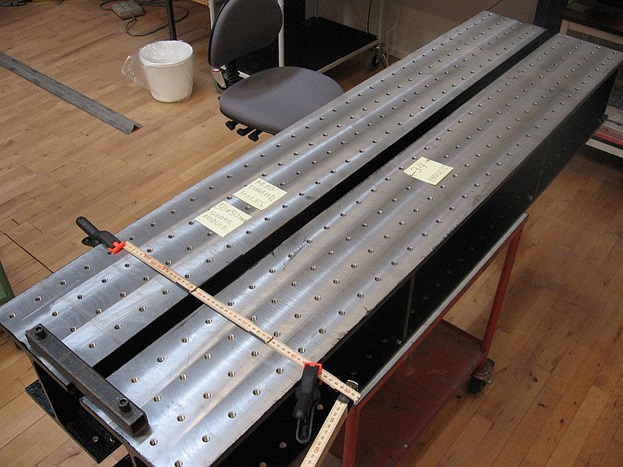

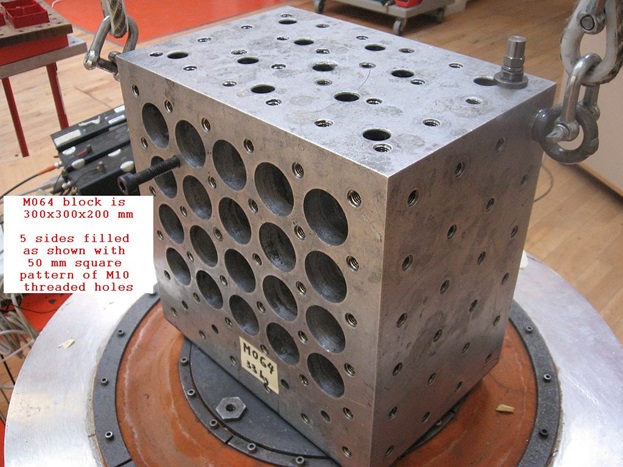

2. Remember to consider the fixture

In general, a test object should be mounted for a vibration test in the same way as it would be during normal use. In order to create a stable and stiff connection between the vibration equipment itself and the test object, it is important to use some kind of fixture. The main purpose of the fixture is to pass on the acceleration level from the vibrator to the test object without adding extra resonances. IEC 60068-2-47 contains good descriptions and useful information about the design and use of fixtures for vibration testing, but it will almost always take time to get a good fixture for a particular vibration test defined. Here are some photos of a couple of FORCE Technology’s standard fixtures.

3. Understand the parameters of acceleration vs. displacement

In general, we would prefer to describe every vibration test as “acceleration of a function of time”, as acceleration is the only absolute parameter that can be used to describe a random movement. However, it can be useful to know the displacement (position as a function of time), as it is this parameter which we can see with our eyes, and which often should be used when we need to link the results from a vibration test up to a calculation of mechanical stress in the test object. You just need to remember that displacement is always a relative parameter, i.e. that you need a reference point in order to measure or in any other way make a statement about a particular displacement. If you know the acceleration as a function of time and frequency, you can calculate the corresponding dynamic displacement. You are welcome to contact us if you would like to receive a small Excel file that can help you to calculate displacement for sine vibration.

4. Know the difference between sine and random

A vibration test can either be a sine test or a random test – but what is the difference, and how can the two be compared? In a sine test, acceleration as a function of time is always a simple harmonic motion (sinusoidal path) with one single frequency at a time, while to put it simply, random vibration has many frequencies at the same time. You can however easily perform a sweep of a particular frequency range during a sine test, but the acceleration signal will always be sinusoidal when you look at single oscillations. In most cases, random vibration more closely resembles vibrations “in real life” and is thus preferable for the majority of applications. IEC 60068-3-8 provides a good summary of various types of vibration and offers some good advice for how best to choose the “correct” test. Click here to receive a free copy of the preview version of

IEC 60068-3-8.

5. Spend time on extra analysis after the test

During a well-planned and well carried out vibration test you can find out whether the test object “passed the test” using specific acceptance criteria, e.g. by examining whether it functioned satisfactorily while being subjected to vibration or without major mechanical damage occurring (there will often be evidence of minor “damage” in the form of wear marks etc.). However, it is advisable to perform a detailed visual inspection of all the parts of the test object in order to reveal any potentially serious degradations or genuine damage that cannot be seen at first glance. One example of this is to check all the electric connectors with a visual inspection using a magnification device to see whether the contact points have been subjected to abnormal wear. It is also a good idea to check the test object’s EMC conditions, if wear is detected on the EMC gaskets.

More info

At FORCE Technology’s vibration test laboratories in Hørsholm, Nordborg, and Aarhus, we have many years of experience with the specification, planning, implementation, and analysis of vibration testing. Please use our contact form if you would like to know more about this.