Training in visual inspection improves Norsyn's supervision of district heating projects

A hands-on training course in visual inspection enhanced Norsyn's technical expertise and improved the quality of weld inspections in district heating projects

Solution

The visual inspection training equipped the inspectors for day-to-day supervision and communication with contractors more effectively.

Result

Norsyn's inspectors gained more substantial technical confidence, improved collaboration, and enhanced quality in weld assessments.

Challenge

Norsyn wanted a shared frame of reference for supervising district heating pipes, due to the inspectors' varied technical backgrounds.

Further training to ensure quality supervision

Supervising welds in district heating projects requires technical insight and the ability to make quick, well-founded decisions. At Norsyn, a consulting engineering company specialising in district heating and construction, inspectors come from various professional backgrounds, which required upgrading the entire team's skills. "We needed further training to establish a shared basis for assessing quality – especially regarding visual inspection," says Mike Jarvig, Senior Specialist and Technical Advisor at Norsyn.Practical knowledge with immediate application

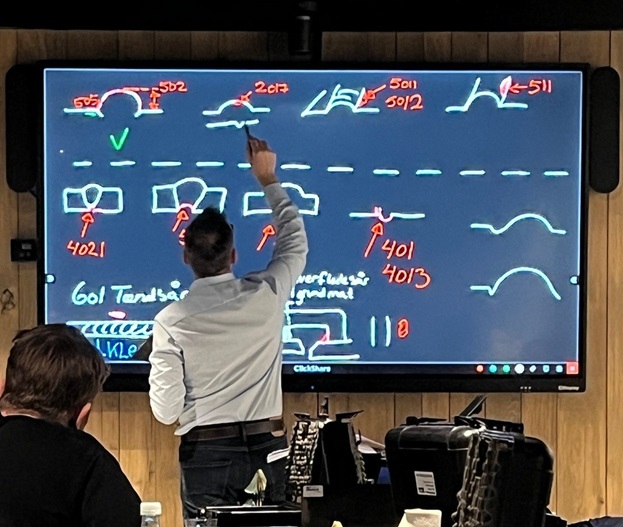

The solution was a tailored internal training course in visual inspection, developed in collaboration with FORCE Technology. The course lasted two days, with a two-week break in between to allow participants to test the methods and tools in practice.The first day focused on fundamental standards and prerequisites for visual testing. Using welded components with known defects, participants worked with inspection tools and hands-on exercises. The second day concentrated on the inspection role, contractor collaboration, documentation requirements and NDT activities.

"It was essential that the training reflected our reality. Our people learn best by doing – not by sitting still and listening for hours," says Mike Jarvig.

Upskilling improves judgement and reduces misunderstandings

The course has had a noticeable impact on daily supervision and is now part of the onboarding process for new inspectors. Staff feel better equipped to identify defects and assess when action is needed, and their technical confidence has grown.

"Today, our inspectors reach out faster when in doubt – which is a crucial culture to build. Our goal is not for them to become welding experts. But they must be able to spot when something is wrong and know when to act. We have gained that understanding, which makes a real difference," explains Mike Jarvig.

Collaboration with contractors has also become easier. Inspectors can now argue more clearly why a weld is unacceptable – and what needs to be done to correct it.

"This helps prevent conflicts and makes the dialogue more constructive. We are in a stronger position as the client's eyes on the project," concludes Mike Jarvig