Hygienic Design Risk Management

If your company is certified under FSSC 22000, BRCGS, or an equivalent GFSI-recognized certification program, managing risks related to equipment design, application, and maintenance will be a key area of focus.

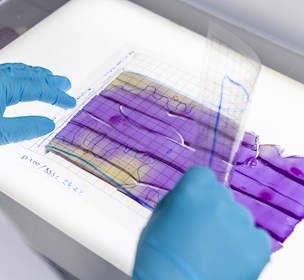

The latest versions of both FSSC 22000 and BRCGS certifications introduce new guidelines for equipment management in food manufacturing. These requirements emphasize the importance of considering hygienic design when purchasing new equipment or modifying existing processes. Hygienic design is crucial for minimizing the risk of microbiological, chemical, and physical contamination in food. By adhering to these principles, food safety can be significantly enhanced.

Operators must learn to comply with these stricter requirements in a beneficial manner. FSSC highlights that essential knowledge about hygienic design and risk minimization can be obtained from the European Hygienic Engineering and Design Group (EHEDG). The theme meeting is based on tools from EHEDG, CFS, and FORCE Technology.

Price: 1.500 kr. On-line participation is possible for the morning part (10.00 – 12.00) for the price of 500 kr.

Trainers from EHEDG and FORCE Technology.

Programme

| 09.30 – 10.00 | Registration |

| 10.00 – 12.00 | Hygienic Design Risk Assessment according to EHEDG guideline 58, as well as relationships to certification and legal demands including references to Global Food Safety Initiative (GFSI). Focus on the new requirements for equipment specification from FSSC 22000 and BRCGS. |

| 12.00 – 12.45 | Lunch |

| 12.45 – 13.30 | Examples from EHEDG guideline 58 and other tools relevant for hygienic design risk evaluation, e.g., based on EN1672-2:2020 and other EHEDG guidelines. |

| 13.30 – 15.30 | Practical work on cases (participants may bring their own case). Topics include specification of requirements, communication between food and equipment manufacturers, risk assessment, and compliance checks via FAT/SAT. Includes a short break. |