Retrofit and life extension of cathodic protection systems

We deliver highly cost-efficient retrofit solutions for life extension and repair purposes.

Our Cathodic Protection (CP) retrofit/life extension systems have been designed based on more than 30 years’ experience with cathodic protection design, computer modelling verifications and offshore inspections. From offering our customers detailed status of their subsea CP, by using FiGS® technology and CP computer modelling we deliver highly cost-efficient retrofit solutions for life extension and repair purposes. Not only will our CP retrofit design be optimised with respect to number and positioning, our CP retrofit sleds are designed for maximum utilisation and handling from shipment, offshore transit and deployment.

FiGS® CP inspection technology

Our FiGS® CP inspection technology can provide current requirement data for optimising the CP retrofit design and solutions for installation for any type of asset (see FIGS)

Our Galvanic Anode Cathodic Protection (GACP) retrofit/life extension sleds are designed compliant with the prevailing standards for offshore lifting and handling to withstand harsh weather condition during deployment.

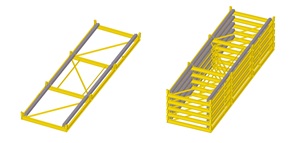

Standardised anode sled solutions

We offer standardised anode sled solutions with optimised anode dimensions and distribution for optimised current efficiency and anode weight allowing short lead time from order to delivery. Our three standardised anode sleds can provide cathodic protection and life extension to any structure in range of anode sleds installed on the seabed. Custom made anode sleds can be designed upon request.

With our partners in Scandinavia and United Kingdom we can fabricate and mobilise from several ports minimising logistics and transportation costs.

Features of our anode sled solutions

All our anode sled solutions are fabricated and delivered with following features:

- Volume/surface area ratio optimised for deployment through splash zone

- Al-Zn-In anodes certified according to DNV RP-B401/Norsok M503

- Dual seawater resistant rugged tieback cables to minimise voltage drop

- ROV/diver operable connection clamp systems for any type of structure

- Footprint area optimised for anode current efficiency and logistics

- Stackable (horizontal sleds) for transportation and minimising vessel deck space

- Lifting sling can be delivered upon request.