Laser welding improves productivity and quality

Laser welding improves quality and productivity – simultaneously. FORCE Technology possesses knowledge and equipment to laser weld your items.

Do you weld in large wall thickness or in thin foils? Or in between? Laser welding can increase quality and productivity - at the same time, so you get faster production and better products simultaneously.

Laser welding opens up new possibilities

With laser welding, it is possible to weld thinner or thicker materials than by any other method. In addition, you save time on finishing and money on less scrapping. Laser welding may increase productivity by its speed and, due to automation laser welding ensures a consistent, low error rate.

Compared to traditional MIG/MAG and TIG welding processes, laser welding gives you:

- shorter process time and thus increased productivity

- lower heat input and thus less deformation

- automated welding resulting in a uniform quality

- control of the heat so that even ultrathin or very thick items become weldable.

Laser welding may reduce costs

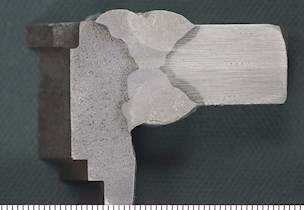

Laser welding may lower the costs in weld production. High welding velocity results in increased productivity, and a higher quality and less scrapping are typically achieved. Laser welding reduces thermal deformations and stresses, and the dimensions of the item remain practically unchanged after welding. At the same time, you achieve a finer surface quality with less spraying and a narrower weld seam.

- nozzle houses, high volume, high velocity

- window lists in aluminium for double-glazed windows

- plastic welding in the pharmaceutical industry

- thick plate welding with laser-hybrid welding.

- welding of magnets

- construction steel

- stainless steel and alloys

- aluminium

- titanium

- plastics

- items holding magnets or electronics or other temperature-sensitive components such as sensors.

Let us help you get started with laser welding

- design of items and joint preparation

- tolerances

- choice of laser type (YAG, CO2, diode, disc or fiber laser)

- laser safety

- pilot production.

Downloads

Facility

Laser centre - centre for laser welding

Services

WPS - Welding Procedure Specification

Get help designing the required WPS so your welders can perform the welding work.

Engineering critical assessment of welded structures

Is it safe to keep using a structure with flaws, without any risk of failure?

Laser safety - get the necessary risk assessment

Lasers are subject to EU directives and AT's regulation, and require regulatory risk assessment.