Load, stress and vibration measurements for structures and machinery

We perform direct measurements of loads, deformations, stress, strains and vibrations, for general purposes and specialised projects.

A direct measurement approach combined with engineering tools provide knowledge on the condition of structures and machinery. It is an easy way to verify loads, stress, strains, structural strength/fatigue or vibrational response.

High class direct measurements for low cost

FORCE Technology offer direct measurements in various forms. Our primary tool for direct measurements is strain gauges These small measuring devices have a clear advantage in both price and measuring precision. Strain gauge measurements can be carried out on various materials such as steel, concreate, composite materials, etc.

We offer the service of long-time structural monitoring (several years) or shorter measurements with a frequency up to 50 kHz (0.02 ms). Measuring precision is 0.5-1 μstrain (0.2 MPa in steel) within a spectrum of 0 to 10.000 μstrain (2000 MPa in steel). This is formula one worthy measuring technology, with a price tag for general purposes.

Typical applications would be verification of loads (an alternative to load cell technology), design optimisation, design strength and fatigue life, weld fatigue analysis, failure analysis, Engineering Critical Assessment (ECA/fitness for purpose), FE model calibration, verification and integrity analysis.

What is a strain gauge, and how to use it?

The most common type of strain gauge consists of a resistance wire which is fixed to the structure. When the structure is loaded, the strain gauge resistance changes, and this change shows you the structure’s strain and stress. Strain gauges often comes in physical sizes from 1 mm to 10 mm in length.

The common strain gauge is glued to the surface of interest with super glue. Data is collected using a data logger, and subsequently stored on a PC. Based on the measured strains, you may calculate the stress, loads, deformations or vibrational response

What are the typical applications for strain gauges?

As mentioned above strain gauges can be installed on various materials, structures and machinery. The typical applications are:

- Steel structures

- Bolts

- Pressure equipment

- Bridges

- Machines and machine components, also rotating parts and bolts

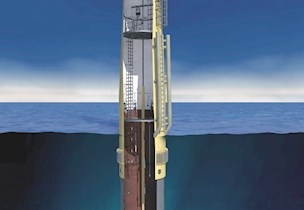

- Offshore structures

- Concrete structures

- Wind turbines

We also offer remote monitoring on e.g. offshore wind turbines. This way you can monitor the actual strains and stresses in real time or download saved data for analysis on a regular basis. The remote monitoring tool helps ensure structural integrity and prevents structural failure.

Please contact us, if you have any measuring applications and wish to know more about how you can benefit from a direct measurement.

Selection of critical areas on structures:

Fitting of strain gauges:

- What you want to measure

- The material you measure on

- The environment you measure in.

We can help you choose the correct strain gauge, with fitting of it and possible protection of the strain gauge that suits your needs.

Setting up of data collection system:

We can put a complete data logging system at your disposal, which you can either rent or buy as you please.

Analysis of measuring results:

Services

Monitoring of offshore wind turbine foundations

Our monitoring system for wind turbine foundations gives you early warning of possible flaws.

Status assessment and inspection

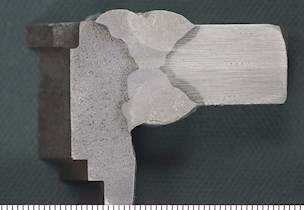

If failure is not acceptable, it is necessary to perform status assessments at suitable intervals.

Engineering critical assessment of welded structures

Is it safe to keep using a structure with flaws, without any risk of failure?