Aerodynamic tests for offshore structures

We perform wind tunnel studies for the offshore industry on numerous types of offshore structures: FPSOs, GBSs, SPARs, semi-submersibles, LNG-terminals and wind turbine installation vessels.

Our extensive experience and our five in-house wind tunnels supplemented by CFD calculations form the basis of our aerodynamic consultancy.

Our aerodynamic services provided to the offshore engineering, operators and construction industries are carried out by FORCE Technology’s Maritime Division previously known as the Danish Maritime Institute (DMI). The services include:

- wind and current loads

- analysis of smoke dispersion

- helicopter operation studies

- anemometer calibration curves

- wind comfort studies

- flow field measurements and visualisations

Wind and current loads

Any vessel or platform will be subject to considerable wind and current forces during operations. This affects the operational requirements, stability, manoeuvring, mooring and propulsion.

Wind tunnel tests at the design stage can be used to assess the environmental loads acting on the vessel or platform. The environmental loads are important with regard to propulsion, manoeuvring, dynamic positioning, mooring and stability. Thruster units can be dimensioned to handle manoeuvring up to a certain wind speed, as dynamic positioning units can be dimensioned to a certain combination of wind and current speeds.

To determine the environmental loads, the above-water part of the model is exposed to a wind profile, which resembles an ocean wind with regard to velocity distribution and turbulence intensity. The underwater part is exposed to a uniform wind profile with low turbulence intensity to resemble a vertical current profile.

We have developed a software tool, DPLab, for analysing the holding capability of a vessel or platform with dynamic positioning. The wind and current load coefficients derived from wind tunnel tests are used in the program to simulate the correct environmental loads.

Analysis of exhaust plumes – smoke dispersion

A platform or offshore vessel can be subject to unfavourable wind conditions when at sea. It is essential for the operator that the vessel is operational at all times. Adverse wind conditions can severely decrease the exhaust stack or funnel performance, thereby leaving outdoor working areas or ventilation inlets engulfed in smoke.

Ship designers and owners face a major challenge to ensure that smoke nuisance on such outdoor areas is minimised, thus enabling the crew to work without experiencing the discomfort of smoke or noxious gases, e.g. SO2 and NOX, near ventilation inlets. The latter – if exceeding given exposure limits – can cause severe health problems and cause shutdown of the vessel in periods of operation.

Helicopter operation investigations

A large number of offshore platforms and vessels are equipped with a helicopter landing deck or helicopter operation zones (e.g. winching zones). The helicopter landing deck and operation zones can be used for commercial, exploration or safety purposes. Especially for safety purposes, a permanent serviceability even under difficult and adverse wind and sea states is of paramount importance.

Testing a model vessel in a wind tunnel experiment at an early stage of the design is an ideal tool to explore potential risks concerning helicopter operations. We have decades of experience with wind tunnel testing related to helicopter operations.

Anemometer calibration curves

Any anemometer installed on a vessel will be subject to the local flow field. By testing a model of the vessel in the wind tunnel, the ratio between the relative wind direction and wind speed to the undisturbed true wind direction and wind speed can be determined and presented in term of anemometer calibration curves. Having accurate data on the wind speed and direction is important in terms of both helicopter operation, harbour manoeuvring and dynamic positioning situations. Furthermore, the anemometer calibration curves can be used during sea trials to correct for the wind resistance.

Wind comfort

Open areas on offshore vessels are often subject to strong wind due to the wind speed at sea and the wind speed created by the ship’s forward motion. The same applies to outdoor working areas on service vessels, drill ships etc. These environmental conditions typically reduce crew comfort or sets expensive limitations to the working time. Therefore, it is important to take the wind comfort into account in the design stage of the vessel.

To meet the comfort criteria, it is essential to produce reliable data on the implications that the local gusty winds will have on the actual design of the recreational or working areas.

Facility

Wind tunnels

Related services

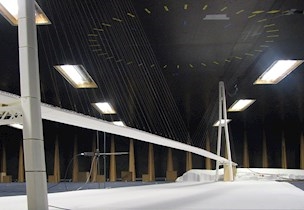

Aerodynamic assessment of bridges

/Service

Test of components, sections and scale models of bridges.

Aviation aerodynamics

/Service

Aerodynamic services related to the operation of aircrafts and planning of related facilities.

Aerodynamic assessment of vessels

/Service

Wind tunnel test can ensure that the vessel meets the operational and class requirements.

Aerodynamic assessment of wind turbine wings

/Service

Aerodynamic services related to wind energy, e.g. sitting in complex terrain or icing on blades.

Wind loads on buildings and structures

/Service

A good wind environment around a structure or area is central to usability and financial success.