MEGA loop revitalised

The expansion of the laboratory facilities for gas flow calibration at FORCE Technology in Denmark, better known as the MEGA loop project, has been revitalised in the wake of the COVID pandemic.

The MEGA loop project has been long underway and is one of the largest investments in the history of FORCE Technology. As it became apparent that the COVID-19 could have a long-term effect on the Oil and Gas industry, the MEGA loop was put through a series of stress tests - socially, technically, economically and financially during 2020 to confirm the relevance of the new facility.

From these tests, it was concluded that the MEGA loop is still a key parameter in meeting customers from the entire natural gas value chain with an increased and in-demand capacity in flow calibration.

Revitalisation to adapt the MEGA loop to the latest insights

The MEGALOOP has thus been revitalised in regards to technical capabilities and futureproofed towards the changing energy mix. The main enhancements to the project are:

- The MEGA loop will be hydrogen ready (initially up to 25% hydrogen content)

- The MEGA loop will be split into two independent calibration strings

- The MEGA loop will be larger than first intended in the initial phase.

The COVID-19 pandemic has had an impact on the industry, but our customers are still introducing gas flow meters and spools that are getting larger by the year – and to meet the demands for increased capacity, reduced waiting times and calibration of all meter sizes and systems, we have decided to make the MEGALOOP larger from the beginning, even though we thereby have to postpone the opening to 2023. We believe, it is the best solution for our customers.Jesper Busk, Vice President of Gas Flow / FORCE Technology

Existing calibration technology magnified

Once finalised, the MEGA loop will add more capacity to the existing facilities in terms of both better time slots and additional space for all meter sizes and metering lines in both the upstream and downstream sector.

Upon delivery of the first stage of the project, the MEGA loop will have the following specifications:

- Flow of 65.000 m3/h

- Pressure up to 65 bar g

- Dp over the MUT system up to 1,5 bar

- Meter lines of 48 meters in length

- 30” lenght compensator with a horizontal movement of 2 meter

- Meter sizes up to 56” - 60”

The proportions of the MEGA loop will open for new opportunities for calibration of long meter systems with two meters in series, which has been in high demand from end-users in the upstream and downstream sectors for many years.

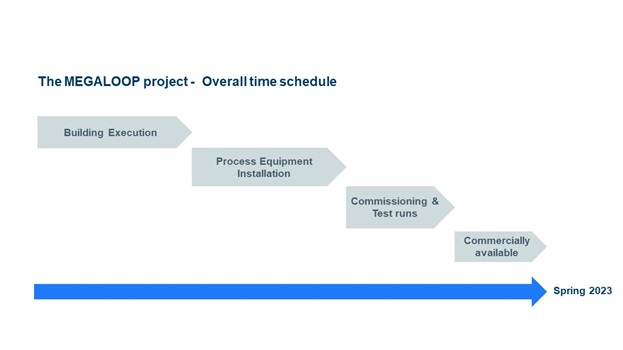

The first calibrations at the MEGA loop are expected to be performed in the spring of 2023.

For any further questions, please contact Vice President of Gas Flow Department, Jesper Busk.