Batteryless electronics

Get advice about how to get started with realising energy harvesting.

With the spread of more and more smart-products, the Internet of Things (IoT), and wearable gadgets of all shapes and sizes, the need for changing and charging batteries will only become greater and greater. This growing number of batteries is not only bad for the user experience but even worse for the environment. Therefore, a lot of people are looking at batteryless solutions, where energy is harvested from the surrounding environment through light, motion, temperature gradients or radio frequencies.

Sweet-spot in microwatt – milliwatt range

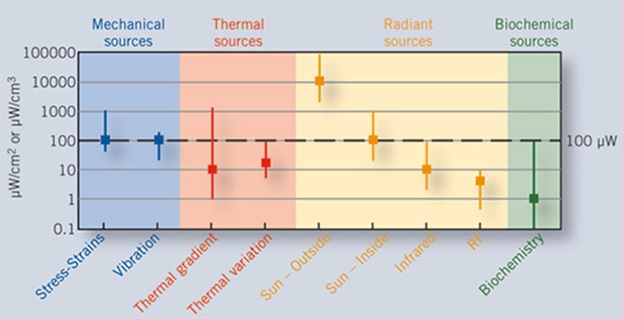

Energy harvesting is particularly relevant for products that have a low energy consumption in the range 100 µW – 5 mW, as many energy harvesting technologies lie in the energy density of 100 µW/cm, as shown in figure 1.

A standard button cell battery CR2032 can supply 1 mW for more than 45 hours, but when we go down to a consumption of a few µW, where the button cell battery can last for 2–4 years, in many cases it is not profitable to use energy harvesting because the battery can last for the lifetime of the product.

With the outdoor solar cell as their benchmark, a lot of people have high expectations for the performance of other technologies, which, however, often have completely different energy conditions. The sun is our most energy-rich source and therefore cannot be matched.

The primary barriers in wireless battery solutions

There are several barriers that need to be overcome if wireless battery solutions are to be realised. For a company that has a battery-driven product, it can be difficult to assess the potential for energy harvesting.

Read also: Powering IoT sensors using ambient energy

The surrounding environment and practical circumstances mean everything in energy harvesting

Several questions rise: E.g. how much light is there actually on the wall in the office or by the machine in the production centre, with what frequencies will vibrations arise on the engine, and how large a temperature gradient is there actually between a particular hot water pipe and the surrounding air?These questions must be known before it can be assessed whether there is potential for making the product energy self-sufficient. Likewise, it must be assessed how energy harvesting technologies work in practice in contrast to a datasheet, which provides peak performance during perfect conditions, something which is rarely achieved in the real world.world. At the same time, the practical implementation is another factor where the final installation has a big impact on the angle of the solar cell compared to the light source, the thermal generator’s contact with the heat source, the vibration harvester’s mechanical connection to oscillating movement, etc. This is challenging compared to just integrating a battery. Functional prototypes should, therefore, be tested in the intended environment as early as possible during the process.

Power management – the key to a successful battery-free product

Because of natural changes in the product’s surrounding environment, energy harvesting generator technologies rarely produce a stable 3 V, which batteries otherwise deliver. A converter can deal with a few mV from a thermo-electrical generator at low-temperature differences or over 50 V in the case of a piezoelectric generator in a vibrating environment, while at the same time it must be ensured that the generator maintains its maximum output point.Sourcing of new energy harvesting technologies

Some technologies for harvesting energy from the surrounding environment are widely available, while other technologies are only offered by a single or a just a few suppliers. When assessing which technologies should replace batteries, it is important to evaluate supplier risk.Five tips when evaluating battery-free solutions

- Start by evaluating whether your product is within the 100 µW – 10 mW power consumption range.

- Carry out thorough data logging of the energy level, so that there is a real data basis for assessing the energy potential.

- Make functional prototypes for early testing in the concrete environment, incl. testing of mounting.

- Power management circuits define the efficiency of the energy harvesting generator.

- Keep an eye on the energy harvesting manufacturer’s supply stability.