How to measure and reduce emission of particles and black carbon from ship engines

The IMO has banned the use of heavy fuel oil with a high sulphur content aiming at a reduction of particle emissions from ships by 2020. However, new initiatives are underway from the IMO to regulate black carbon emissions. Learn how MAN Diesel & Turbo and Alfa Laval Aalborg (DK) prepare and optimise measurements of black carbon emissions.

New regulations underway regarding black carbon emissions

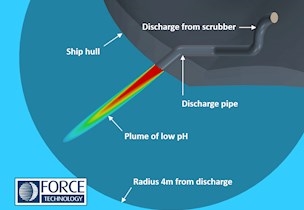

With the reduction of sulphur, emissions of sulphate in the stack gas will be reduced, thereby generally reducing the particle emissions from ships by 2020. However, the content of harmful soot particles – often characterised as black carbon – will not be affected. As black carbon has a global warming potential, the effect of emissions from ships poses a concern to the IMO.

This is specifically the case in the Arctic regions, where the deposition of black carbon particles may cause a strong global warming effect. The IMO is presently preparing a set of regulations for the control of the emission of black carbon from ships.

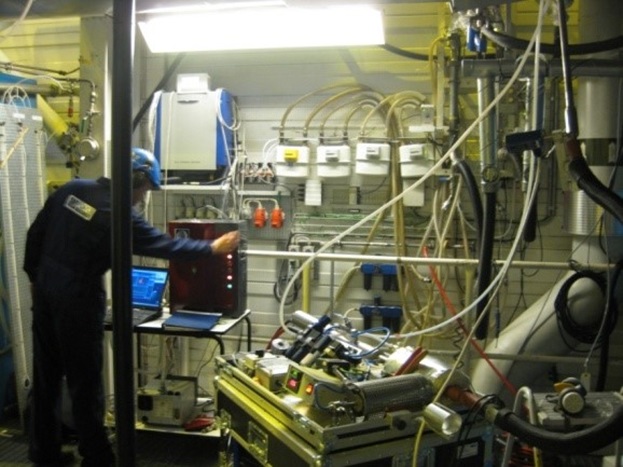

To meet the new initiatives, MAN Diesel & Turbo, Alfa Laval Aalborg and FORCE Technology have developed and tested methods to measure the emission of particle mass and black carbon from ship engines at sea. The aim of the test was to assess the efficiency of exhaust gas cleaning equipment with respect to reducing the emission of particles and black carbon from ship engines at sea.

Measurement method: Particle mass (PM)

The reference method for measurement of PM is based on the international standard ISO8178-1. This standard has been developed for test-bed operation and prescribes methods to measure particle mass (PM). With slight modifications, the ISO8178 can also be used for PM measurements according to US regulations (40 CFR 1065 Subpart J).

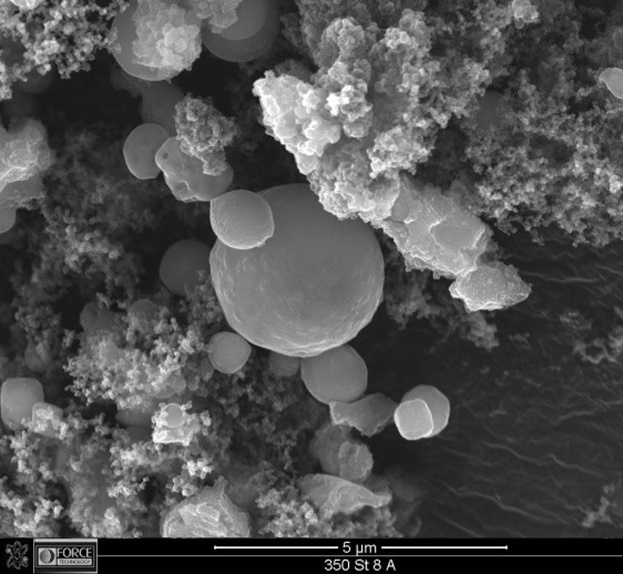

Particles are sampled on a filter after dilution of the stack gas. The dilution step is unique as compared to PM measurement methods used at stationary sources. Dilution has been introduced for PM sampling from large diesel engines because a large fraction of the emitted particles is semi-volatile (e.g. lube oil particles).

The semi-volatile particles would not be included in the measurement result if the hot stack gas was sampled without dilution. The objective of introducing a dilution step in the ISO8178 measurement is to simulate the amount of total PM emitted to the atmosphere, i.e. the total PM formed in the plume after the exhaust gas has been cooled to atmospheric conditions.

In order to use the equipment at sea during actual operation, the equipment has been downsized and validated.

Black carbon emissions measurement

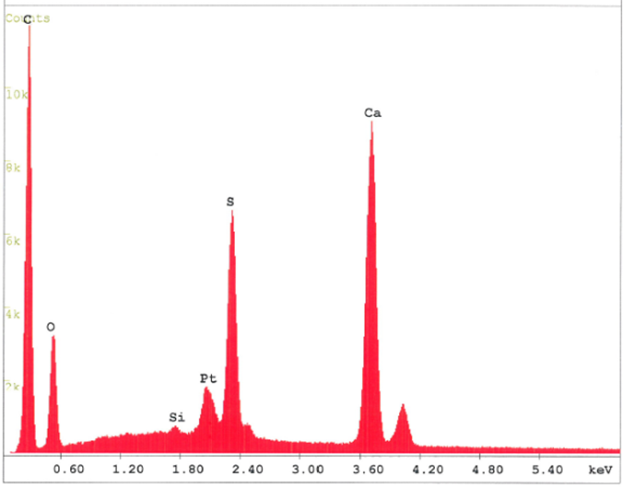

One of the reference methods for measurement of black carbon (BC) was performed by analysis of the particles collected on the filters by means of the PM equipment described above.

The content of black carbon was analysed through thermal-optical analysis, giving the result for elemental carbon (EC). EC was used to express the content of black carbon in the sample.

Results of the field test

As part of the Blue INNOship project “Scrubbers – controlling PM emissions”, the measurement equipment was tested at MAN Diesel & Turbo’s test site in Copenhagen, and at Alfa Laval’s test site in Aalborg. The results showed that the downsized equipment performed well compared to the reference equipment, and that results could be reproduced within a relative standard deviation of 10 % at steady state engine load.

The method is therefore now offered to ship owners in order to test the efficiency of exhaust gas cleaning equipment with respect to reducing the emission of particles and black carbon from ship engines at sea.

Future outlook

As the IMO is gradually moving towards the implementation of a regulation for the emission of black carbon, we have experienced an increasing interest for monitoring of particle mass and black carbon.

Ship owners and suppliers of exhaust gas cleaning (EGC) equipment wish to prove the efficiency of EGC to reduce particle mass and black carbon.

In the future, it is expected that EGC equipment such as scrubbers must be optimised to reduce not only sulphur emissions, but also emissions of particles and black carbon from ship engines.