Neutron analysis helps life science company Glysious develop adhesive patches

We have supported Glysious with advanced neutron techniques to improve their understanding of the Glysious material and, thereby, optimise the delivery of therapeutic drugs in a controlled way.

A counter-intuitive material with promising applications

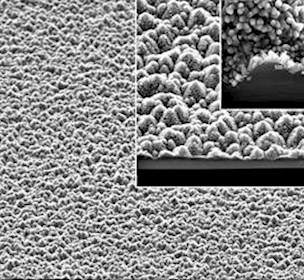

The Glysious technology is based on silicone rubber with microscopic glycerol droplets inside. The material combination is not supposed to be stable, but Professor Anne Ladegaard Skov and her team at the Technical University of Denmark have invented a technology to stabilise it. Silicone on its own is impervious to water, but the embedded glycerol droplets act as reservoirs for active substances like drugs. When the patch is placed on the skin, glycerol absorbs sweat and the patch releases drugs onto the skin. The spinout company Glysious is commercialising the technology.Microstructured elastomer material is tricky to characterise

The material's functionality depends on how the glycerol is distributed inside the silicone. However, the structure is complicated to study. For instance, using a microscope for assessment requires that the material is cryo-cut, i.e. frozen and cut into thin slices, which requires expertise, is time-consuming, and only provides information about a limited sample section.

Neutron analysis is the solution

We have identified neutron analysis as the ideal method to characterise the Glysious material. The neutrons allow you to see the inside of compound polymer materials, supported by relevant parts of the material being highlighted by the use of heavy water.

Neutron experiments are performed in a nuclear reactor. We have access to a large network of neutron facilities worldwide and can therefore identify the right technique and facility for a given challenge. The European Spallation Source (ESS) facility in Lund, Sweden, will become our go-to neutron facility upon its planned inauguration in 2025 due to its unprecedented scale and the wealth of opportunities it will offer local and global businesses. In the Glysious case, the research reactor at the Technical University (TU) of Delft in the Netherlands was identified to be the best fit for the challenge. In collaboration with Dr Wim Bouwman from TU Delft, the plan for measurements was developed. The samples were prepared by Glysious, inspected by Bouwman and his team upon arrival, and we analysed the data.

Structure revealed new insights

The analysis showed that the glycerol in the samples is evenly distributed as 3 μm spheres in the silicone matrix. The determination of the size distribution of the spheres also provided powerful insights: All the (heavy) water in the system was located in the glycerol droplets, thereby discarding the hypothesis that the water flows in channels created by the glycerol droplets within the silicone matrix.

This knowledge is essential for Glysious when designing patches to deliver therapeutic drugs in a controlled and targeted way to the skin and/or a wound, both from a modelling perspective and to predict long-time stabilities. Compared to other methods like microscopy of cryo-cut specimens, the neutron method analyses the entire sample rather than a tiny fraction and is significantly less time-consuming. The results will be published in a scientific article by Glysious.

Get access to neutron analysis

Analysing your material with neutrons can be helpful when the important structures are hard to observe with conventional microscopy or X-rays. This is relevant in any polymer production process where you want to see water/hydrogen, composite materials, or biological materials in solution, to name a few. We are experts in neutron techniques and have contacts with relevant global facilities.